Mold structure of water outlet of silica-gel gondola water faucet

A water outlet and shower technology, which is applied in the field of the mold structure of the water outlet of the silicone shower, can solve the problems of random shooting, messy burrs, and oblique water spraying, and achieve the effect of wide application and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in further detail below in conjunction with accompanying drawing (embodiment):

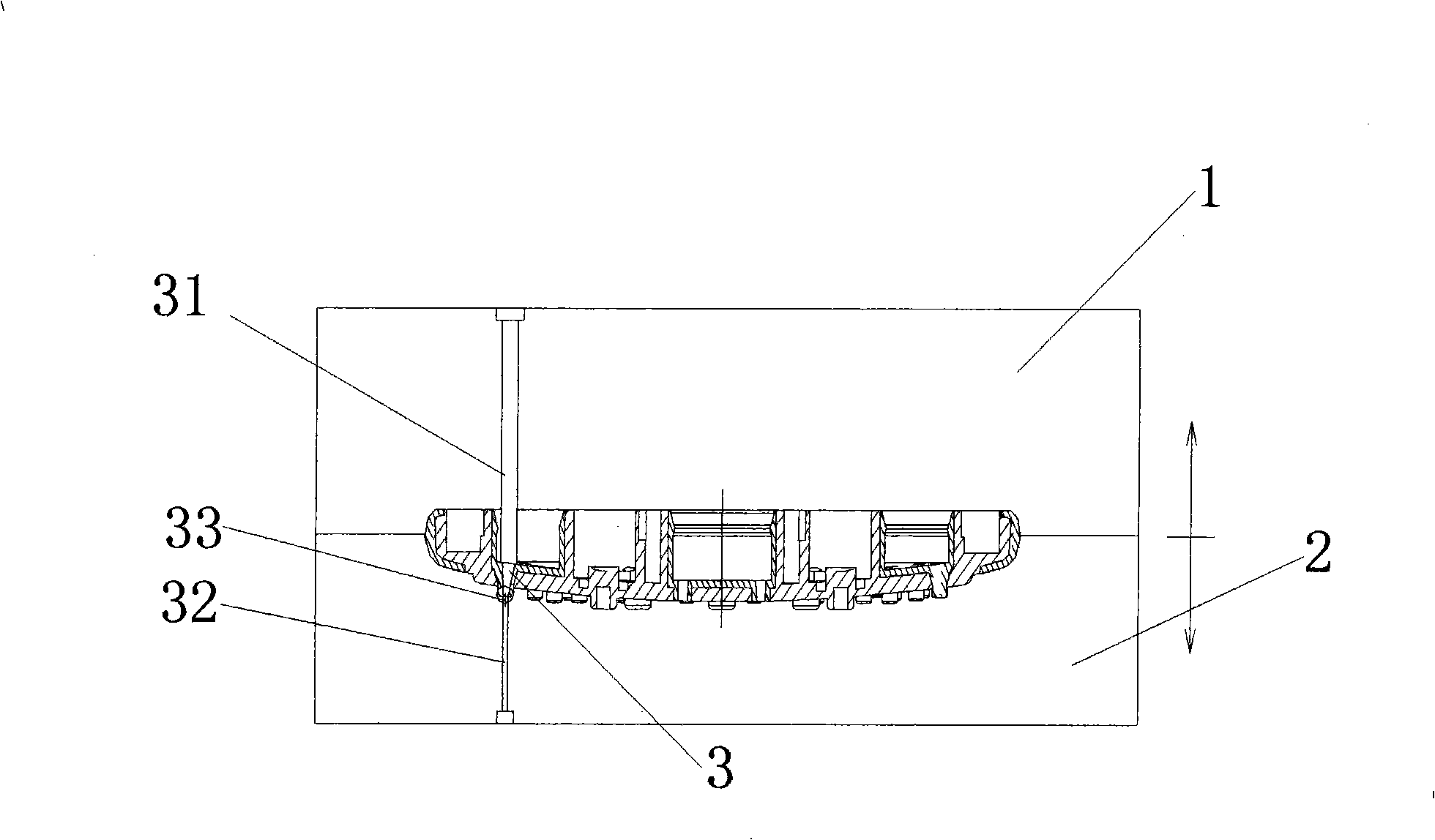

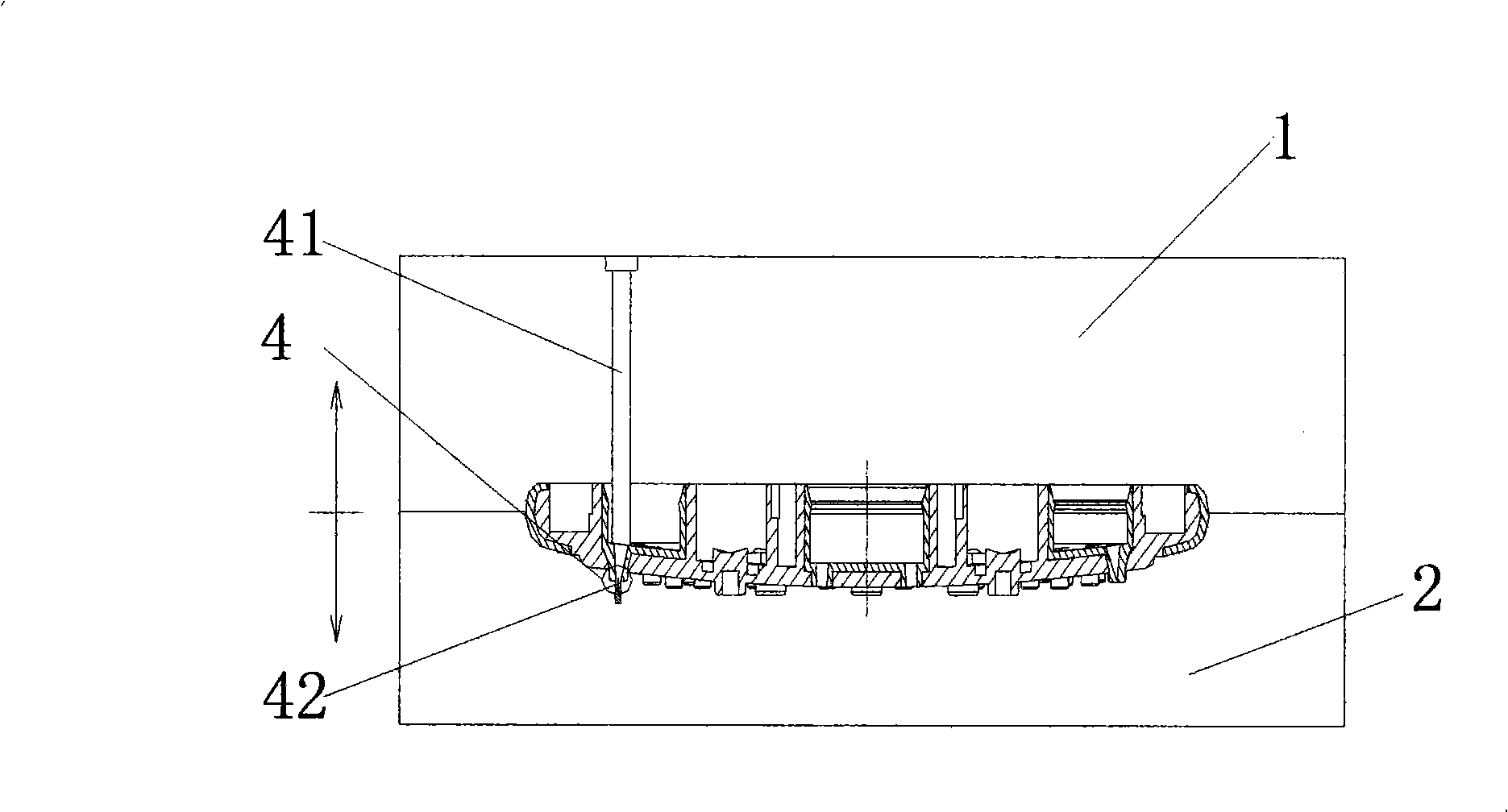

[0015] With reference to accompanying drawing 1, the present invention is made of front mold (fixed mold) 1, back mold (moving mold) 2, bump through structure 3, front mold (fixed mold) insert pin 31, back mold (moving mold) insert needle 32, touch The piercing position 33 is formed, and the penetration structure 3 is set at the small end face of the needle outlet hole of the front mold (fixed mold) 31 and the back mold (moving mold) 32 .

[0016] The puncture structure 3 described above includes a front mold (fixed mold) insert 31, a rear mold (movable mold) insert 32, and a puncture position 33, and a front mold (fixed mold) is set on the front mold (fixed mold) 1. Insert pins 31, rear mold (moving mold) insert pins 32 are set on back mold (moving mold) 2, front mold (fixed mold) insert pins 31 and rear mold (moving mold) insert pins 32 are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com