Panel with handle and manufacturing method thereof

A panel and handle technology, applied in furniture parts, household utensils, furniture accessories, etc., can solve the problems of unsightly appearance, low yield, and low quality of veneer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The product structure and manufacturing method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

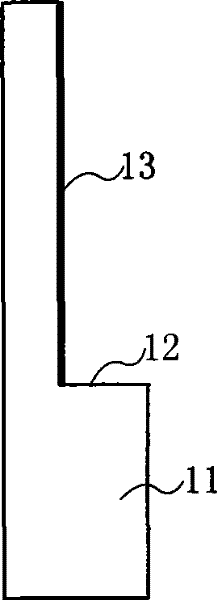

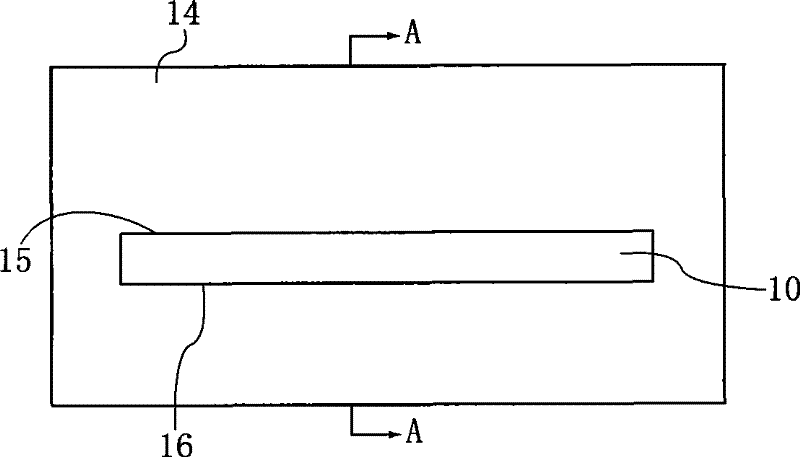

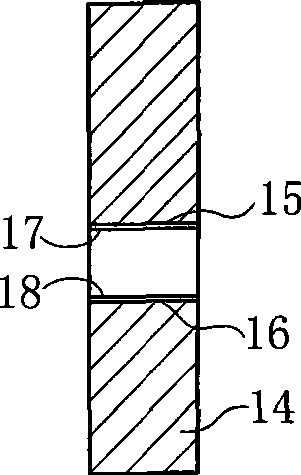

[0040] Such as figure 1 , figure 2 As shown, the bottom plate 11 is selected according to the shape and size of the panel required by the design, and the part 12 for bonding is cut out on the bottom plate 11, and the part 12 for bonding that is cut out is consistent with the size of the upper panel 14. That is, the length, width, and depth of the bonding portion 12 are consistent with the corresponding dimensions of the upper panel 14 . The position of the bonding part 12 is set so that after the upper panel 14 is bonded to the bonding part 12, the position of the handle groove 10 on the upper panel 14 is consistent with the position of the handle groove required by the design. Then, on the portion 12 cut out for bonding on the bottom plate, the facing material 13 is covered at the position c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com