Internal wall panel construction structure capable of mounting and detaching

A technology for building structures and interior wall panels, applied in building construction, construction, covering/lining, etc., can solve undisclosed problems, achieve the effect of preventing damage and improving constructability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

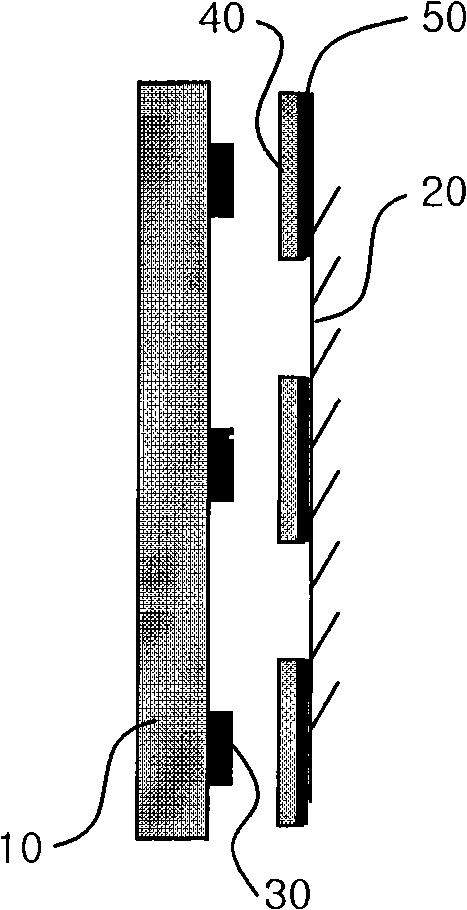

[0046] First, if Figure 4 As shown, three iron sheets 40 are glued on the wall surface 20 by using double-sided adhesive tape 50 .

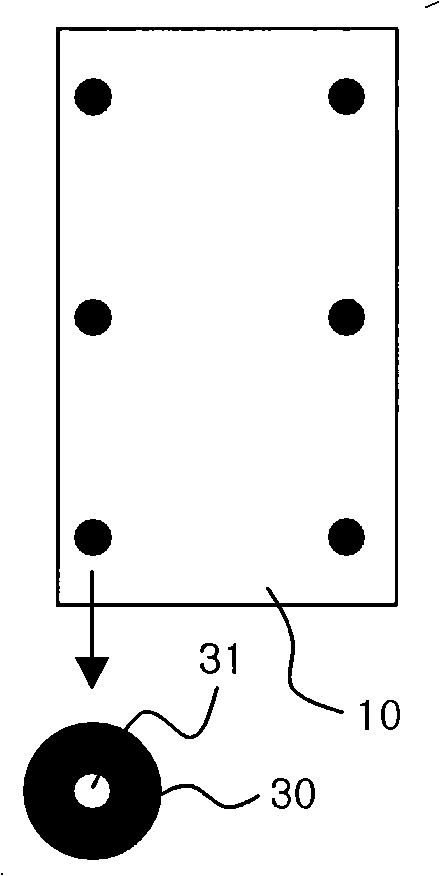

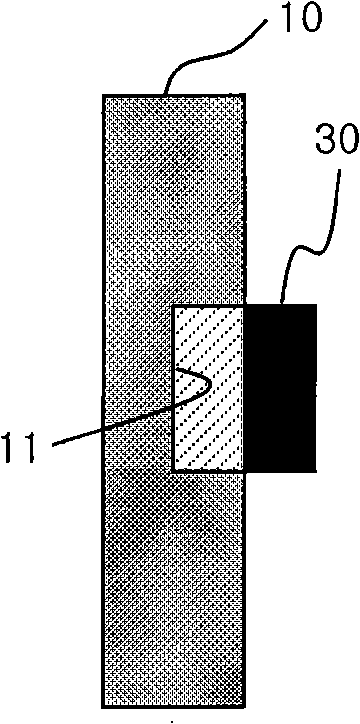

[0047] Subsequently, if figure 2 with 3 As shown, six grooves 11 are formed on the back surface of the interior wall panel 10 . Such as figure 2 As shown, six magnets 30 having screw holes 31 at their centers are inserted into slots 11 and fixed with screws. In this case, the surface of the magnet 30 and the back surface of the interior wall panel 10 form a plane.

[0048] The interior wall panel 10 is constructed by wrapping fabric over a base member of MDF.

[0049] A neodymium magnet with a magnetic force of 2,500 Gauss was used as the magnet 30 . Except for the surface of the magnet that is in contact with the iron piece 40, the other surfaces of the magnet 30 are treated with stainless steel. The stainless steel treatment is performed by a method of inserting the magnet 30 into a cap made of SUS.

[0050] Subsequently, the interio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com