Stepping type non-mask digital exposure device based on digital micro-lens array

A technology of digital micromirror array and exposure device, which is applied in photolithographic process exposure device, microlithography exposure equipment, optics, etc., can solve problems such as difficult to meet, low cost, high equipment cost, etc., and achieve strong technical extension and process compatibility, avoiding high cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

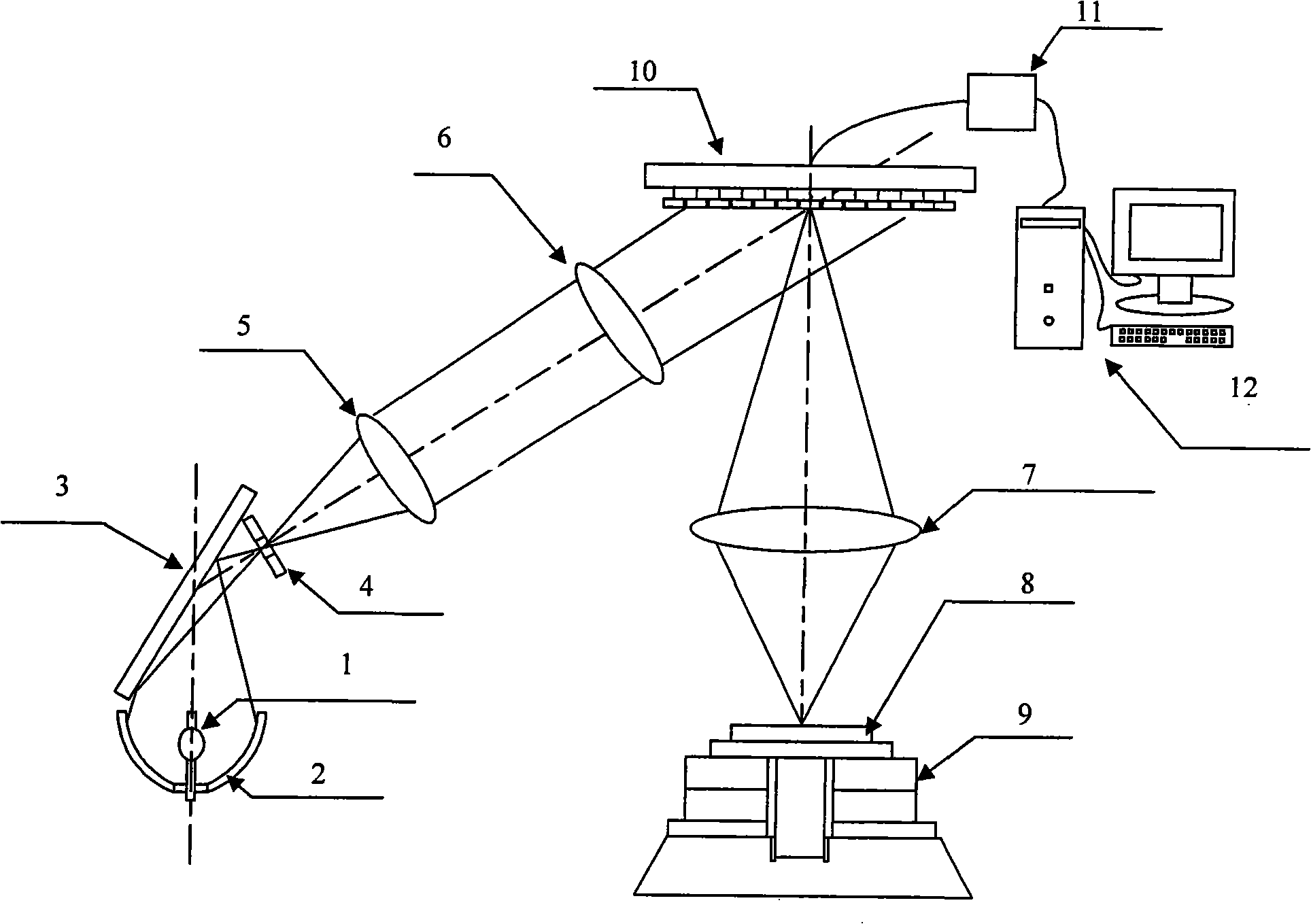

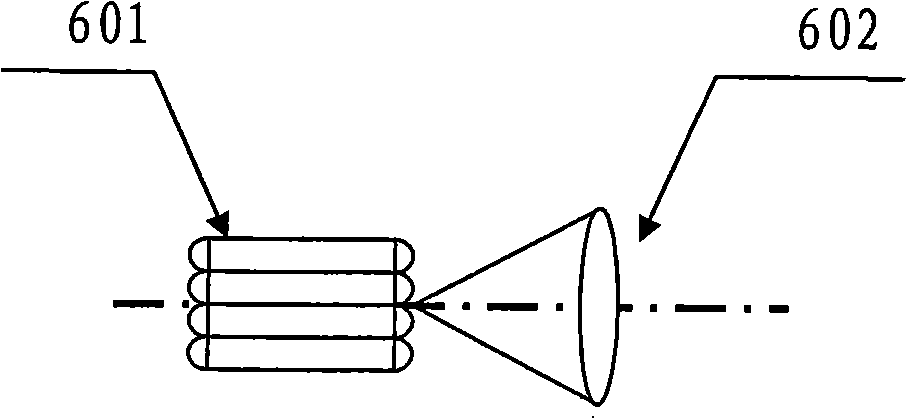

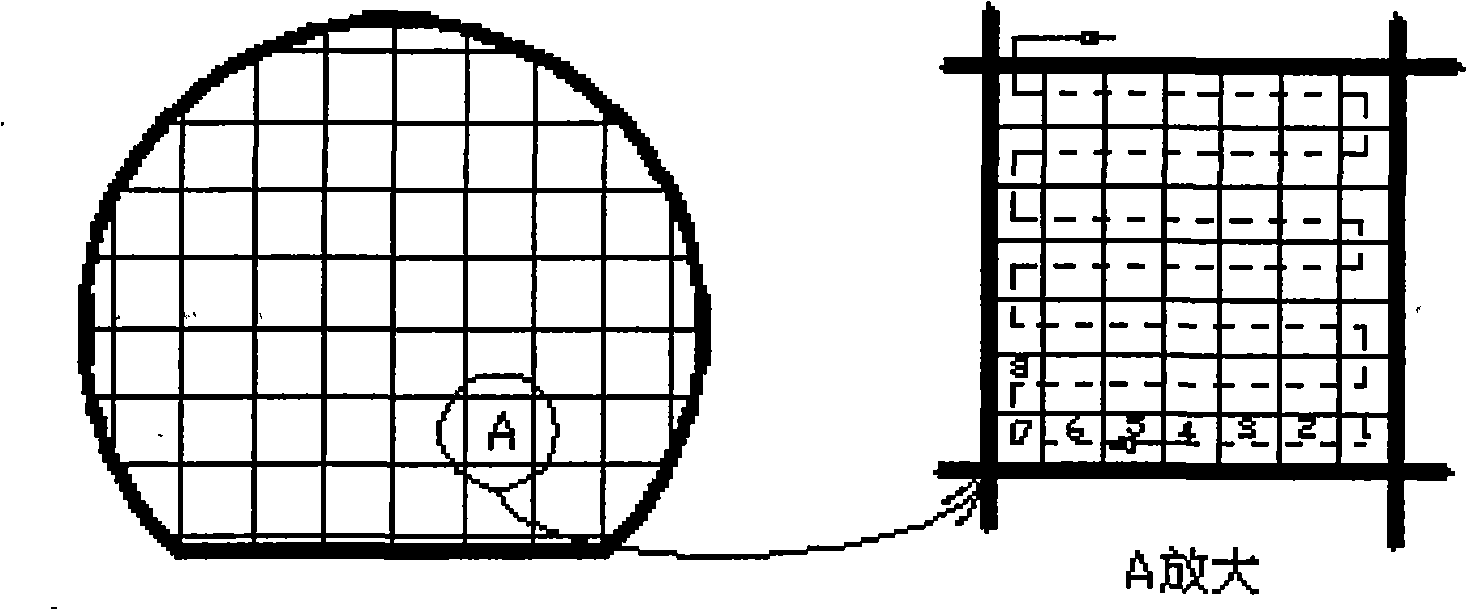

[0028] A step-by-step maskless digital exposure device based on a digital micromirror array in this embodiment is composed of an illumination light source 1, an ellipsoidal mirror 2, a reflector 3, a light block 4, a collimating mirror 5, and an energy integrating homogenizer 6. Projection objective lens 7, lithographic sample 8, X-Y stepping workpiece table 9, digital micromirror array 10, digital micromirror array control card 11, and computer 12; when the lighting source 1 adopts a non-point light source, the light it emits Concentrate the light by the ellipsoidal mirror 2 to ensure that the light energy is fully utilized; the light collected by the ellipsoidal mirror 2 is reflected by the reflector 3 placed at the opening of the ellipsoidal mirror 2 and converges to the light block 4, and the light block 4 will Illumination light source 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com