Multipurpose thermal upsetting die cutter

A multi-purpose, hot heading technology, applied to lathe tools, manufacturing tools, tool holder accessories, etc., can solve the problems of cutter head wear, high use cost, and easy wear of the cutter head, so as to avoid high cost , to avoid the effect of wasting

Inactive Publication Date: 2014-02-12

RUGAO HUIYUAN CASTING

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The hot upsetting die cutter is used for cutting the hot upsetting die. The cutting edge of the current hot upsetting die cutter is directly processed on the cutter body. The disadvantage of this structure is: the current cutter material is mainly high-speed steel and hard alloy , using high-speed steel cutters for hot heading mold processing, the cutter head is easy to wear and needs to be replaced frequently, and if the hard alloy cutter with high hardness and good wear resistance is used, the cutter head wear needs to be replaced as a whole, and the use cost is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

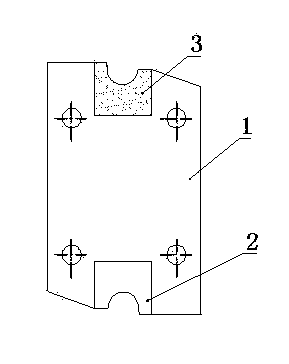

[0007] As shown in the accompanying drawings, including a high-speed steel cutter body 1, a high-speed steel cutter head 2 and a hard alloy cutter head 3 are respectively provided at both ends of the cutter body 1, and the hard alloy cutter head 2 is embedded in the cutter body 1 and is connected with the cutter body 1. The cutter body 1 has an interference fit, and the high-speed steel cutter head 2 and the cutter body 1 are integrally formed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a multipurpose thermal upsetting die cutter which comprises a high speed steel cutter body. The multipurpose thermal upsetting die cutter is characterized in that two ends of the cutter body are respectively provided with a high speed steel cutter head and a hard alloy cutter head which is embedded in the cutter body and in interference fit with the cutter body, and the high speed steel cutter head is integrally formed with the cutter body. The multipurpose thermal upsetting die cutter has the advantages that the end portions of the cutter body are respectively provided with the high speed steel cutter head and the hard alloy cutter head, the corresponding cutter head is adopted according to different machining portions, and the problem that cost is high when the alloy cutter head is exclusively used for machining is solved. If the alloy cutter head is abraded, the alloy cutter head only needs to be detached and replaced, the whole cutter body does not need to be replaced, and waste of resources is avoided.

Description

technical field [0001] The invention relates to a cutting knife, in particular to a multi-purpose hot heading mold cutting knife. Background technique [0002] The hot upsetting die cutter is used for cutting the hot upsetting die. The cutting edge of the current hot upsetting die cutter is directly processed on the cutter body. The disadvantage of this structure is: the current cutter material is mainly high-speed steel and hard alloy , using high-speed steel cutters for hot heading mold processing, the cutter head is easy to wear and needs to be replaced frequently, and if the hard alloy cutter with high hardness and good wear resistance is used, the cutter head wear needs to be replaced as a whole, and the use cost is high. Contents of the invention [0003] The technical problem to be solved by the present invention is to provide a hot heading die cutter with low use cost and long service life. [0004] In order to solve the above-mentioned technical problems, the tec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23B27/16

CPCB23B27/16

Inventor 纪学健

Owner RUGAO HUIYUAN CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com