Optical disk device

An optical disc device and optical disc technology, which is applied in the recording of information on the magnetic disc, instruments, magnetic recording, etc., can solve the problems of lubricating oil leakage, attachment to the optical disc or optical disc device, oil leakage, etc., and achieve high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

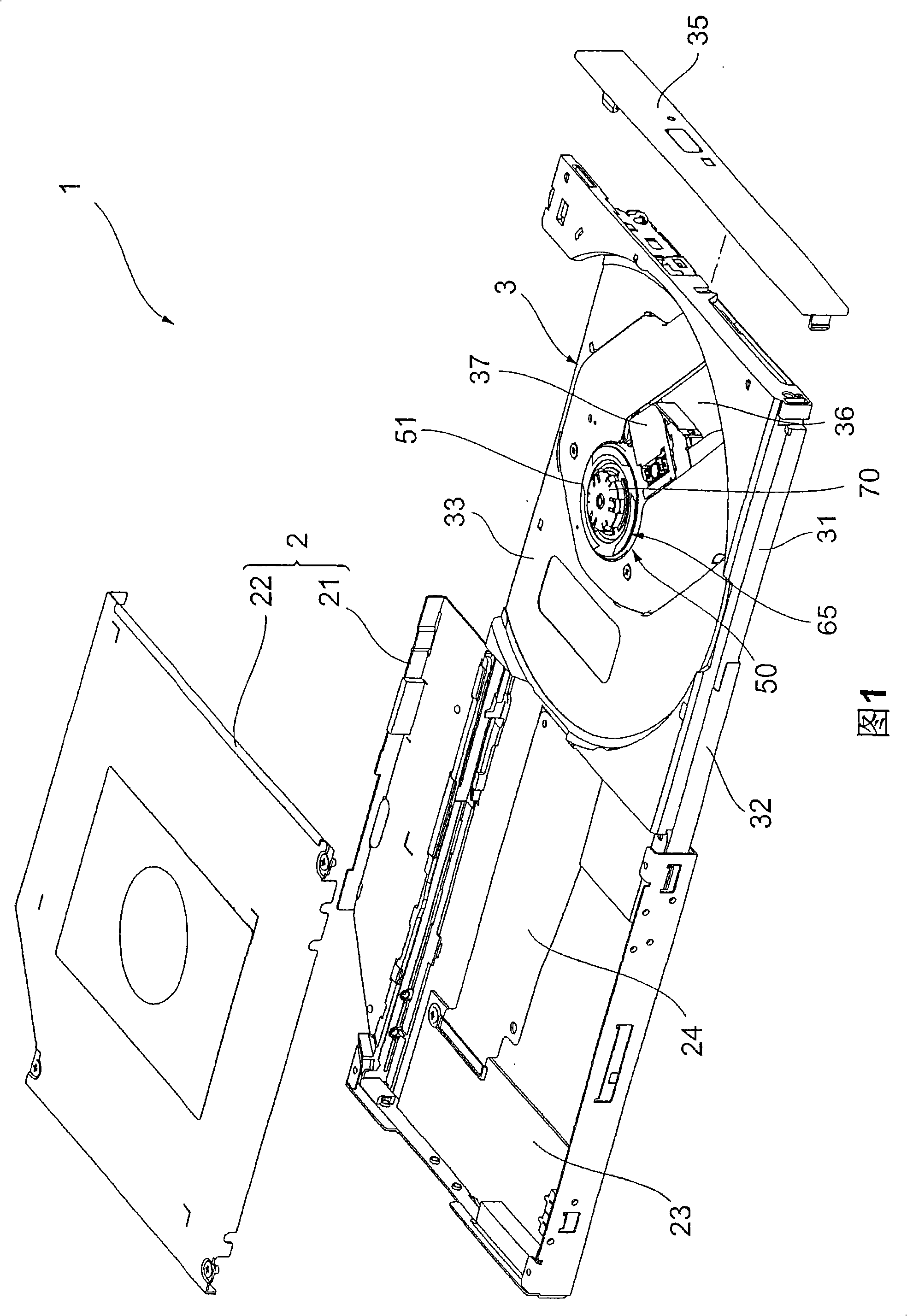

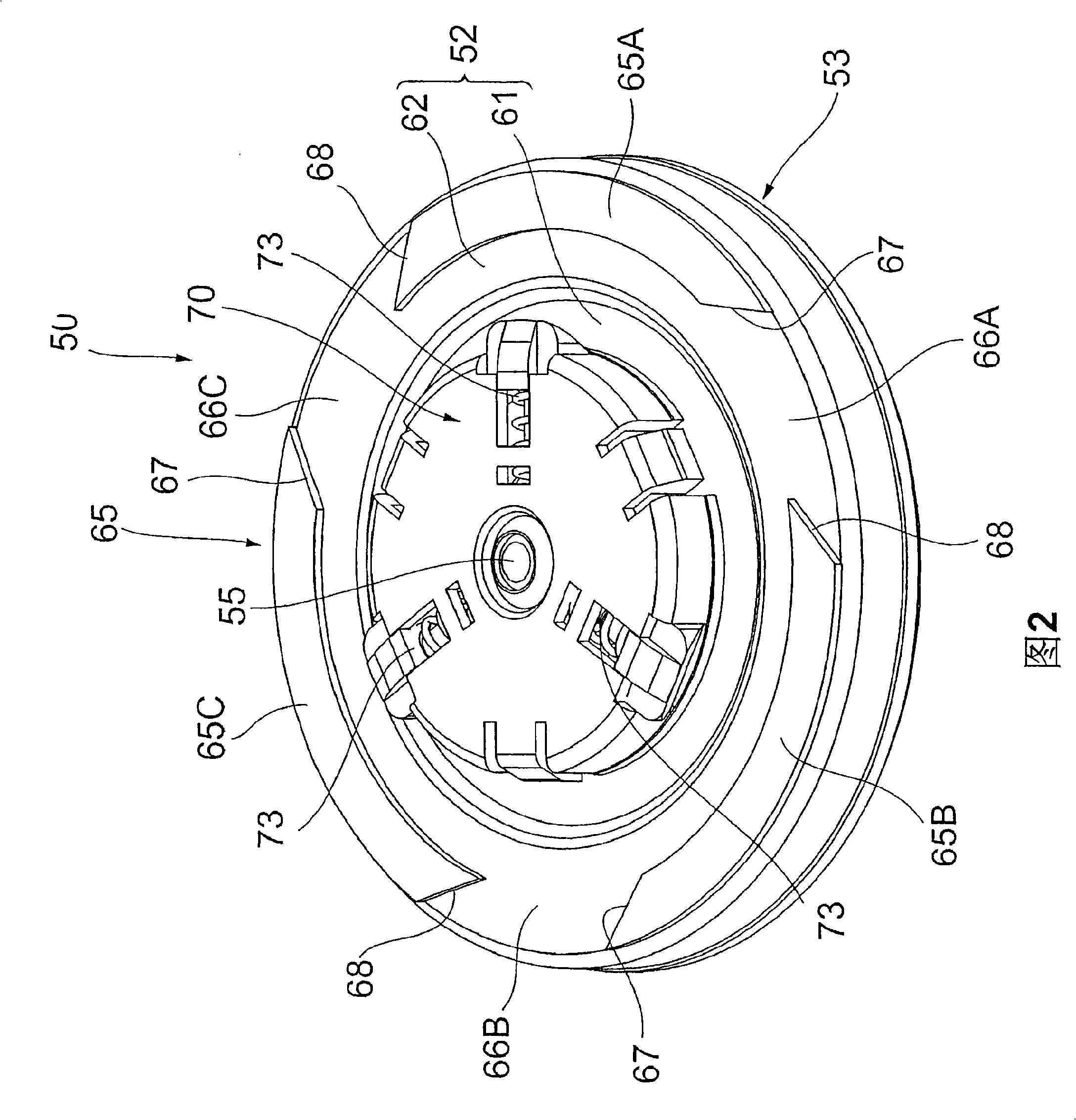

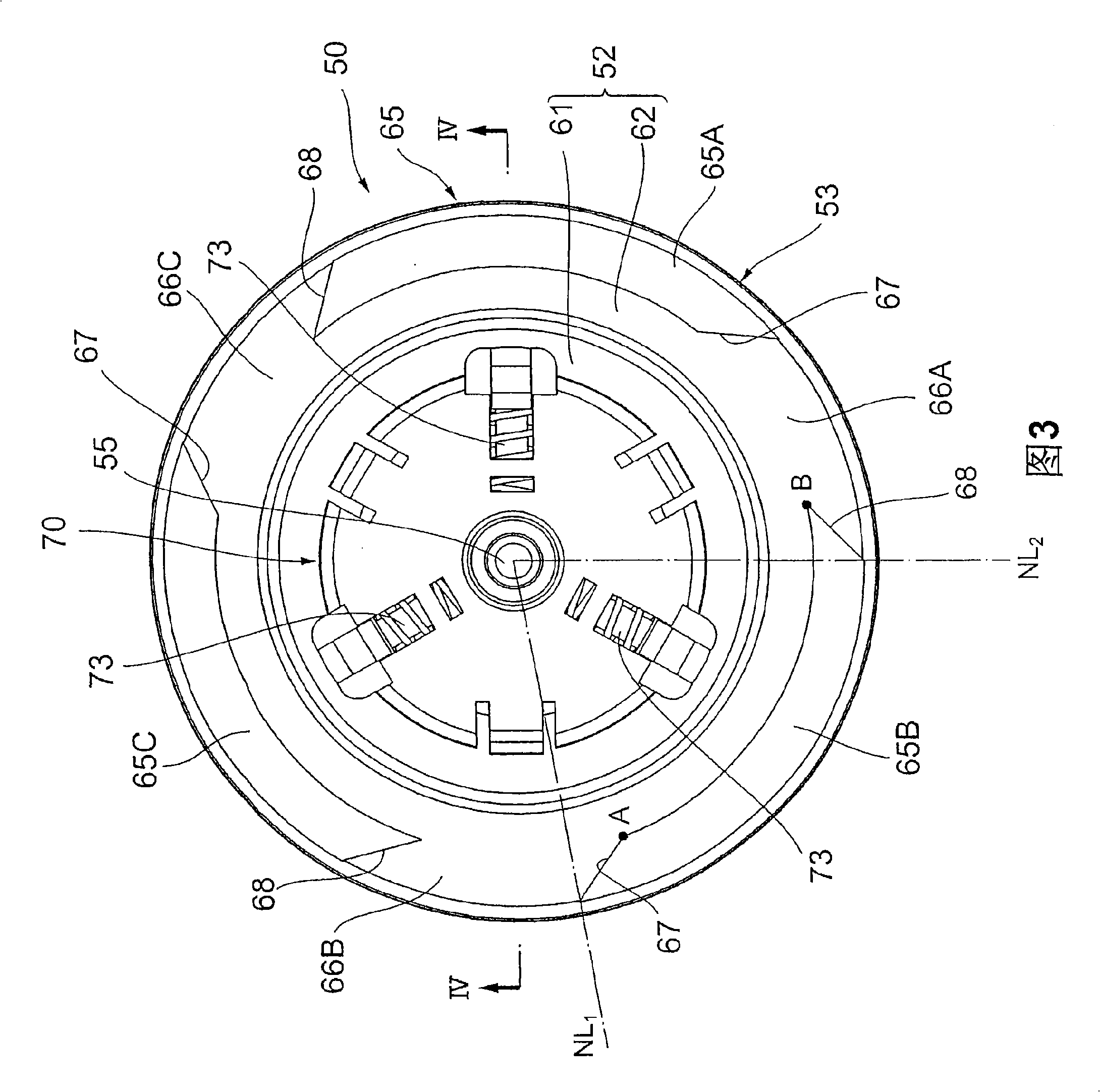

[0034] 1 is an exploded perspective view of an optical disc device according to Embodiment 1 of the present invention. FIG. 2 is a perspective view showing main parts of the optical disc device shown in FIG. 1. FIG. 3 is a cross-sectional view taken along line IV-IV, and FIG. 5 is a view showing a state in which an optical disc is mounted in the optical disc device shown in FIG. 1 on a cross-section corresponding to FIG. 3 .

[0035] In each of the above-mentioned figures, in order to facilitate understanding of the description, there are some parts where the thickness, size, magnification ratio, etc. of each member are not consistent with the actual description. In addition, the optical disk device according to Embodiment 1 will be described as a device that rotates the mounted optical disk clockwise.

[0036] As shown in FIGS. 1 to 5 , an optical disc device 1 according to Embodiment 1 includes a housing 2 and a tray 3 disposed on the housing 2 so as to be detachable. The f...

Embodiment approach 2

[0052] Next, an optical disc device according to Embodiment 2 of the present invention will be described with reference to the drawings. In the second embodiment, the same components as those in the first embodiment are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0053] FIG. 10 is a perspective view showing main parts of an optical disc device according to Embodiment 2, and FIG. 11 is a plan view showing main parts shown in FIG. 10 .

[0054] As shown in FIG. 10 and FIG. 11 , the main point of difference between the optical disc device of Embodiment 2 and the optical disc device 1 of Embodiment 1 is that flow paths 166A to 166C are formed on the disc-facing surface 52 of the rotor case 53 , and flow paths 166A to 166C are formed on the disc-facing surface 52 of the rotor case 53 . An annular support member 165 is disposed on the outer peripheral portion 62 of the surface 52 .

[0055] That is, on each position of the outer perip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap