Middle and small dry powder pressing machine single side ejection mechanism

A demoulding device and demoulding technology, applied in presses, manufacturing tools, etc., can solve the problems affecting the accuracy of the demolding movement of the machine, the inclination of the lower beam, and the processing inconsistency, etc., to ensure the demolding accuracy, reasonable design, and use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

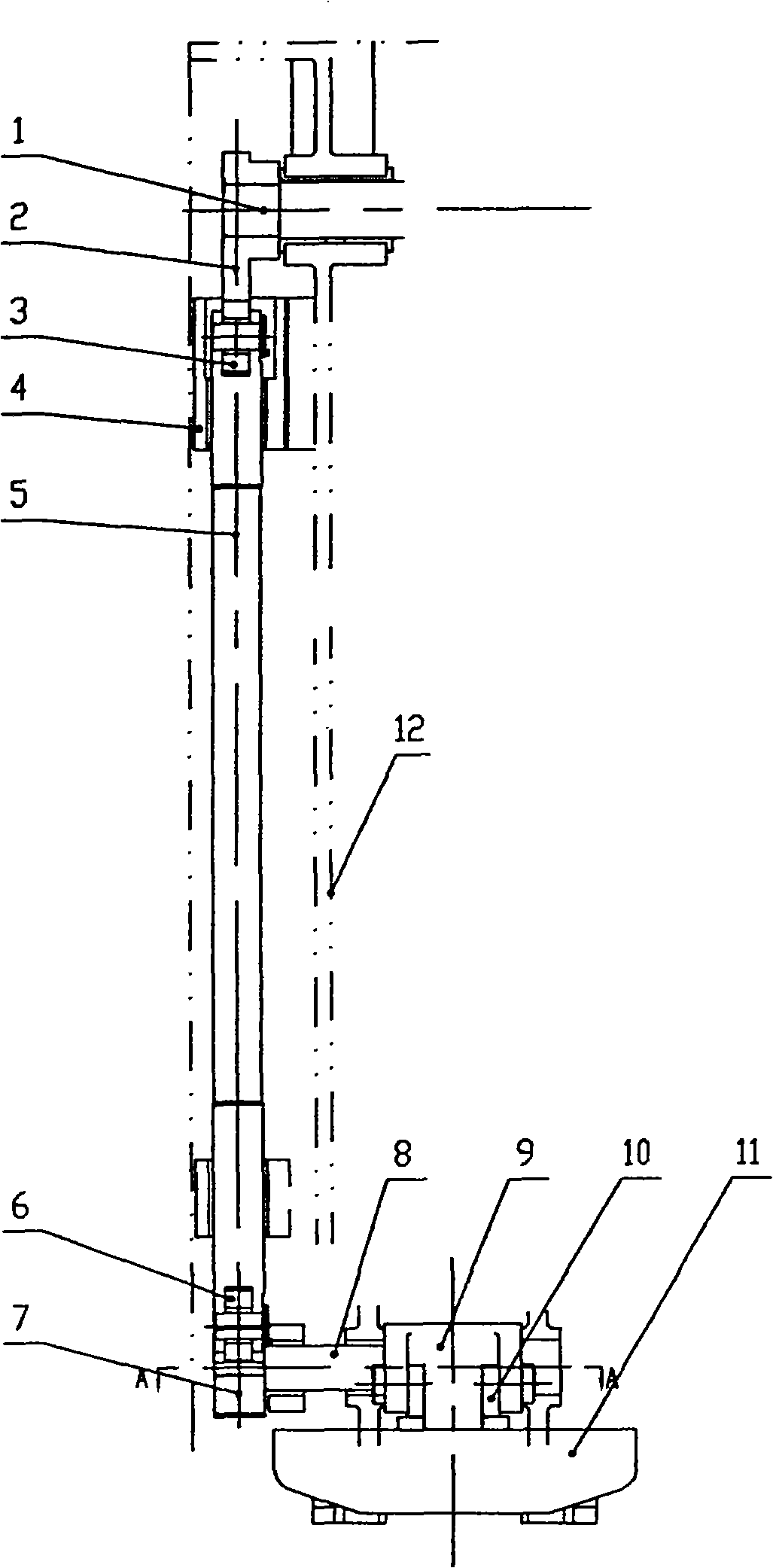

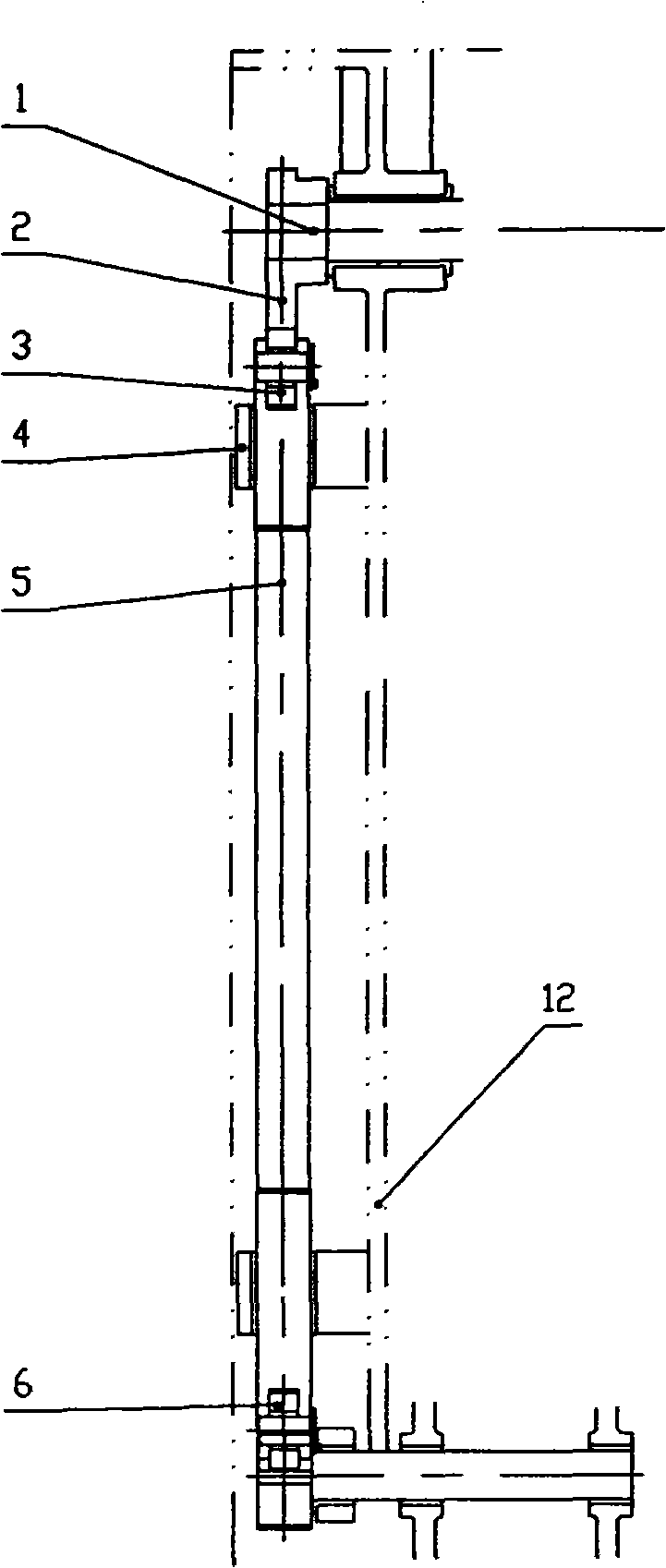

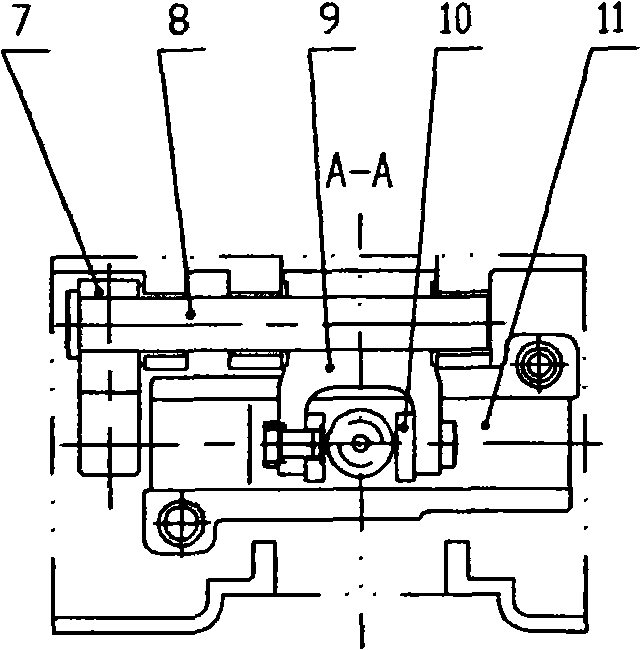

[0011] Refer to attached Figure 1~3 , The unilateral demoulding device of the small and medium-sized dry powder press includes a cam 2, an upper roller 3, a lower roller 6, a demoulding lever 5, a demoulding arm 7, a demoulding shaft 8, a demoulding lever 9 and a demoulding briquetting block 10. The cam 2 is mounted on one end of the main shaft 1 of the dry powder press, the demoulding rod 5 is mounted on the demoulding rod bracket 4, the demoulding rod bracket 4 is mounted on one side of the dry powder press frame, the upper part of the demoulding rod 5 is equipped with an upper roller 3, The upper roller 3 is in contact with the cam 2, the lower part of the demoulding rod 9 or one end of the demoulding arm 7 is equipped with the lower roller 6, the demoulding arm 7 is mounted on one end of the demoulding shaft 8, and the demoulding shaft 8 is mounted on the dry powder press frame 12 On, the demoulding lever 9 is contained in the demoulding shaft 8 other ends, and the demoul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap