Water sotrage bend for water drainage

A technology of traps and drains, applied in water supply installations, indoor sanitary plumbing installations, buildings, etc., can solve the problems of insufficient drainage flow, drainage backflow, unhygienic senses, etc., to solve garbage blockage, improve drainage flow, The effect of increasing drainage flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

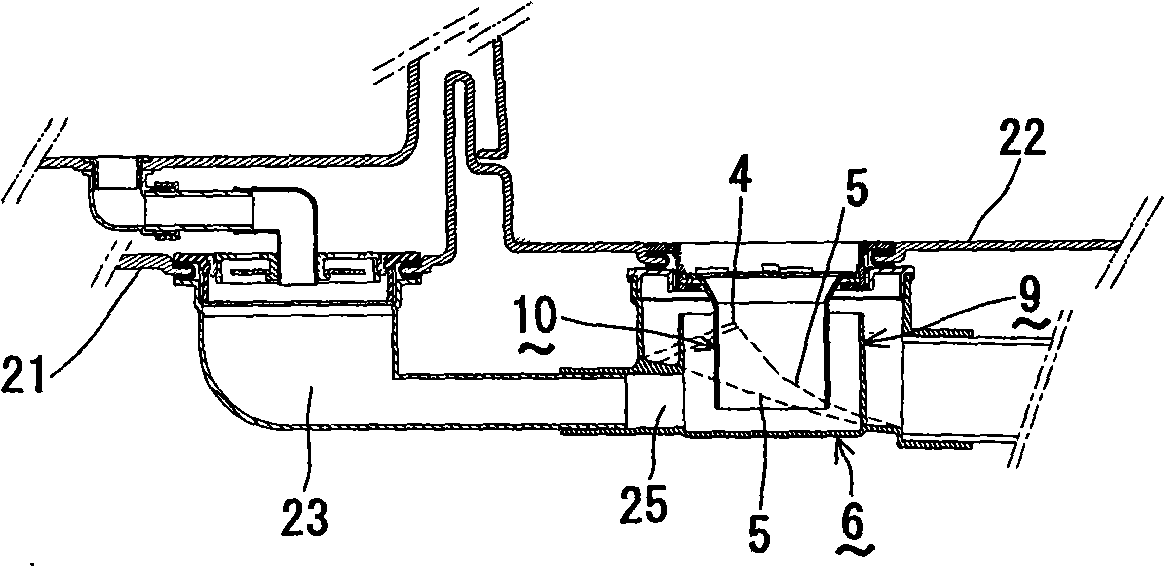

[0024] Embodiment 1 The drainage trap of the present invention is figure 1 , Figure 8-10 drain trap as shown in the illustration. Below, for figure 1 , Figure 8-Figure 10 The embodiment of the drain trap shown in the figure will be described with reference to the drawings. figure 1 , Figure 8-Figure 10 The drainage trap of this embodiment shown in the figure is installed in the bathroom described below. The bathroom is composed of a bathtub, a bathtub base 21 and a washing place base 22 , wherein the bathtub base 21 is used to place the bathtub, and the washing place base 22 forms a washing place adjacent to the bathtub base 21 . In addition, openings are formed on the bathtub base 21 and the washing place base 22, and a drainage trap is connected and arranged on the inner surface side of the openings. The drainage trap is composed of the trap body 6, the flange, the water sealing bowl 9, the water sealing cylinder 10, the sieve plate part 24, and the elbow joint p...

Embodiment 2

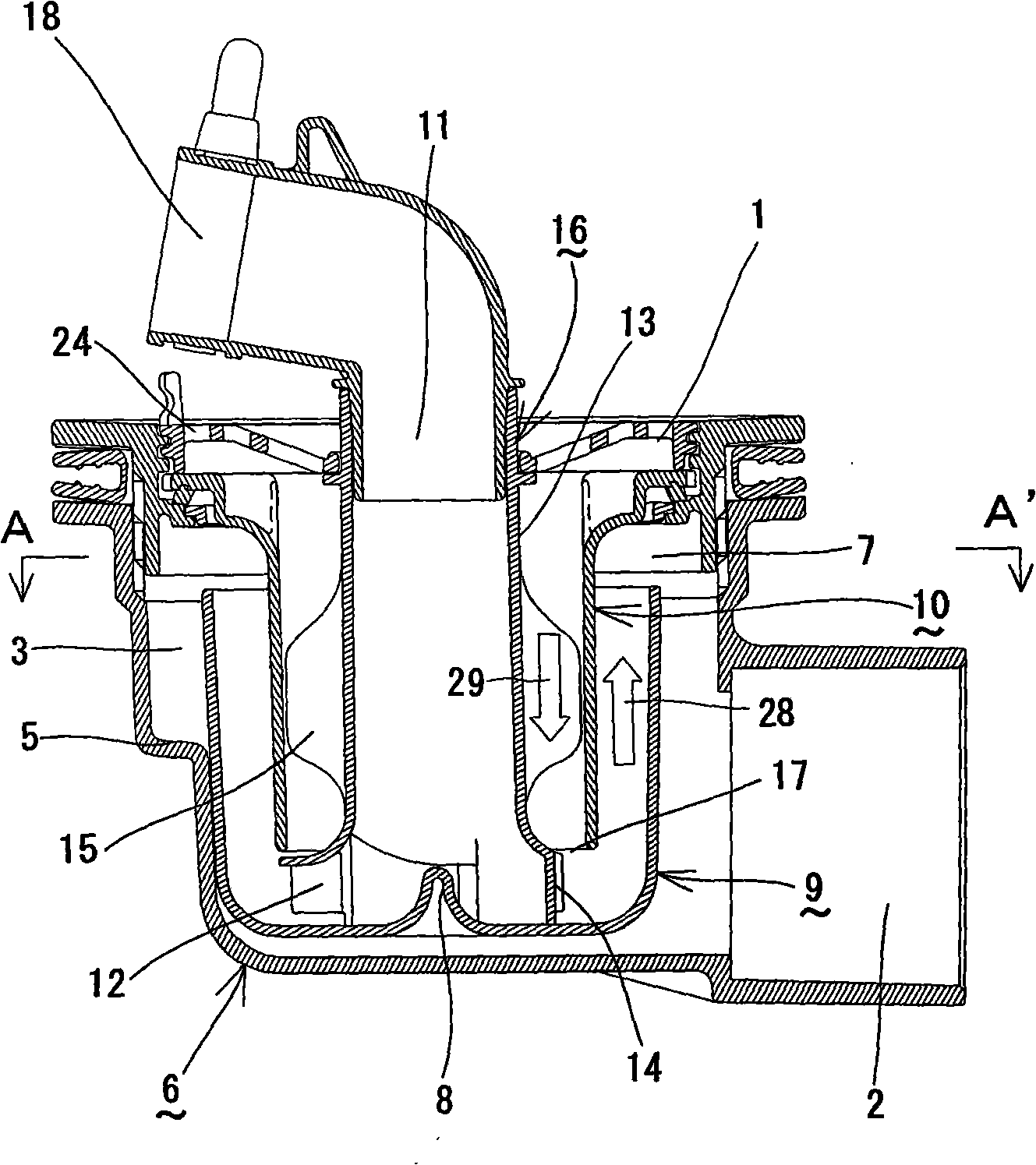

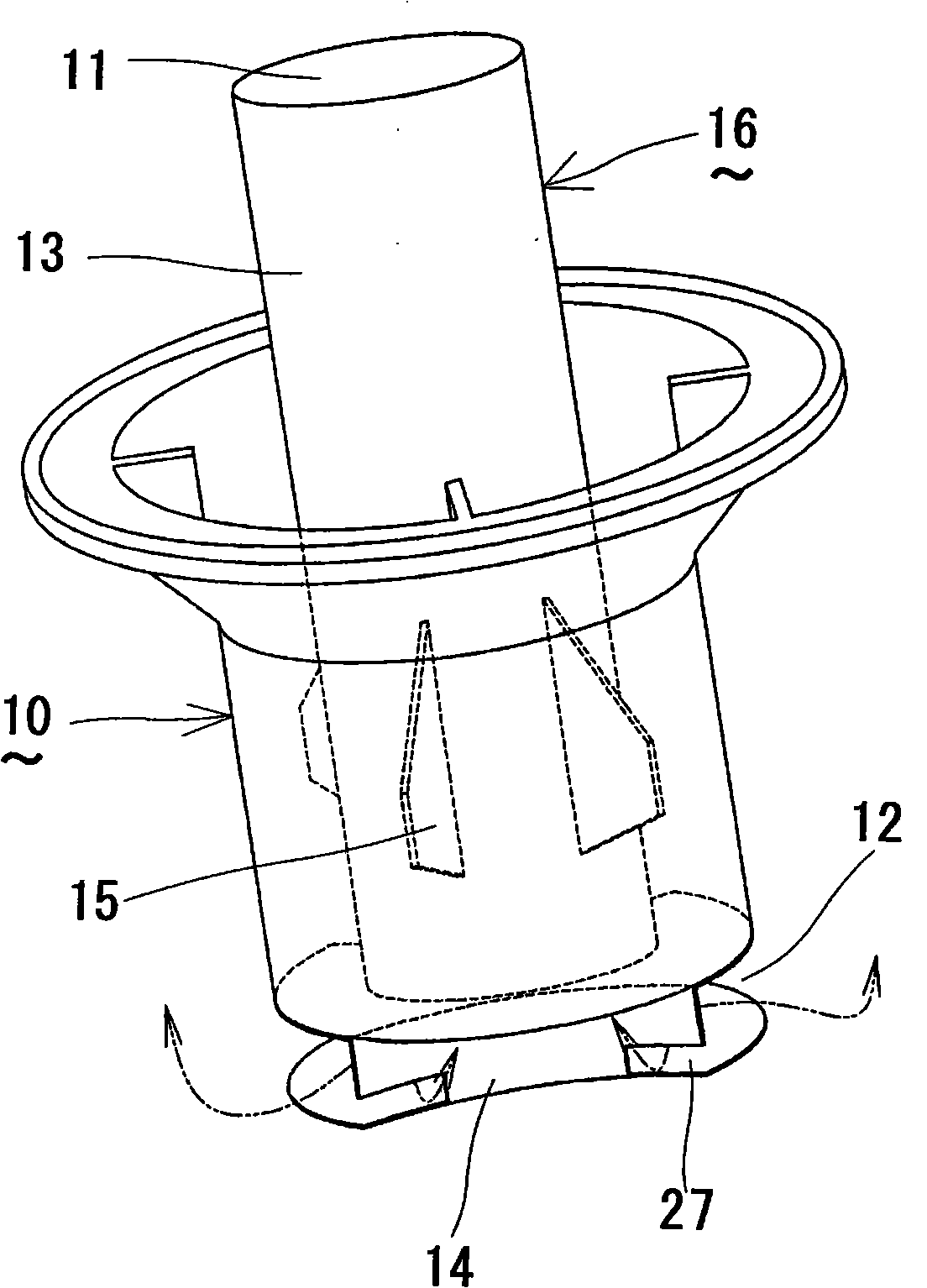

[0026] Embodiment 2 The drainage trap of the present invention is Figure 2-Figure 11 drain trap as shown in the illustration. Below, for Figure 2-Figure 11 The embodiment of the drain trap shown in the figure will be described with reference to the drawings. Figure 2-Figure 11 The drainage trap shown in the figure is installed on the waterproof base 20 for the washing machine described below. The top of the waterproof base 20 for the washing machine is just the washing machine body, and the bottom surface of the waterproof base has an opening. The drainage trap is composed of the trap body 6, the flange, the water sealing bowl 9, the water sealing cylinder 10, the anti-bubble pipe 16, the joint 18, and the sieve plate part 24 as described below. The water trap body 6 is in the shape of a container, and includes: a discharge port 1 through which the upper part of the drain flows in, and a discharge port 2 through which the drain is discharged from the side. In addition, ...

Embodiment 3

[0029] Example 3 Figure 2-Figure 11 The drain trap shown in is installed on the waterproof base 20 for the washing machine described below. The top of the waterproof base 20 for the washing machine is just the washing machine body, and the bottom surface of the waterproof base has an opening. The drainage trap is composed of the trap body 6, the flange, the water sealing bowl 9, the water sealing cylinder 10, the anti-bubble pipe 16, the joint 18, and the sieve plate part 24 as described below. The water trap body 6 is in the shape of a container, and includes: a discharge port 1 through which the upper part of the drain flows in, and a discharge port 2 through which the drain is discharged from the side. In addition, at the discharge port 1, a female thread screwed with the flange described later is processed, and the pipe body is connected to the discharge port 2, and finally connected to the downpipe. In addition, a water sealing bowl 9 to be described later is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com