Air pressure telescopic link

A technology of telescopic rods and air pressure, which is applied in the direction of gas shock absorbers, engine seals, springs, etc., can solve the problems of large automatic changes in the elastic coefficient of springs, the inability to automatically change the expansion and contraction force, and the impact of environmental conditions, etc., to achieve low cost, The spring stretching force can be changed automatically, and the effect is not affected by the climate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific example

[0018] The present invention will be specifically and further described below in conjunction with the accompanying drawings.

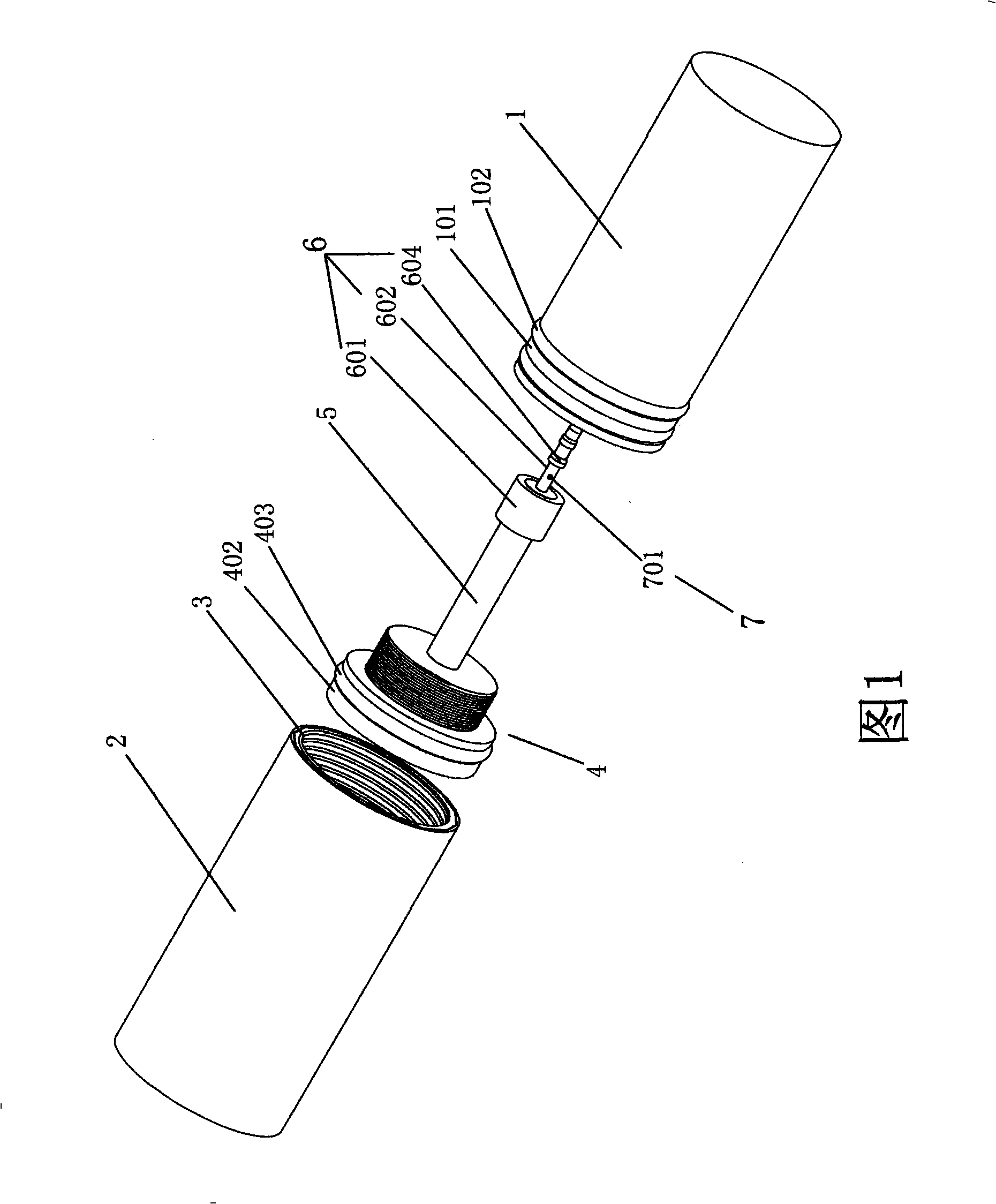

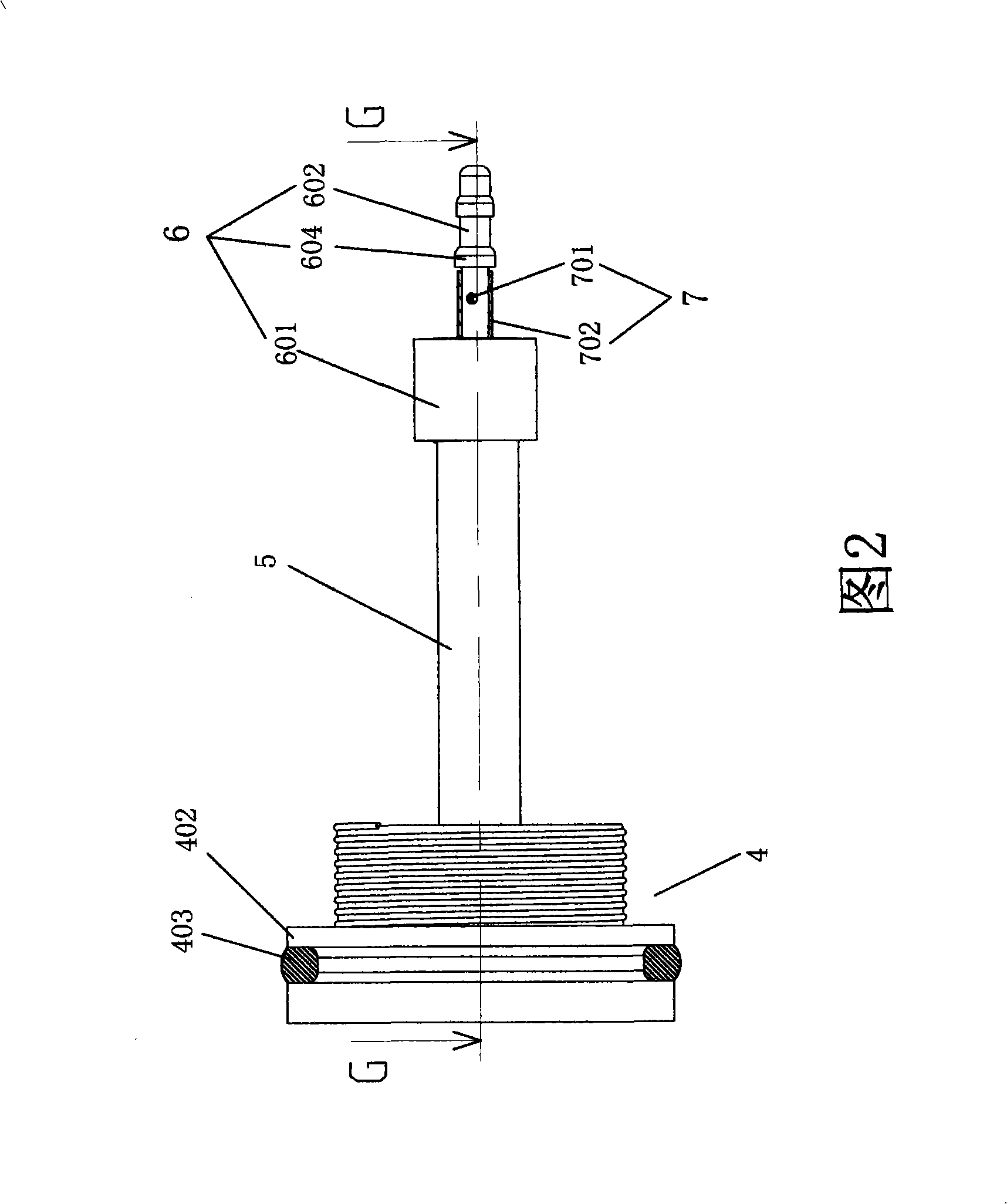

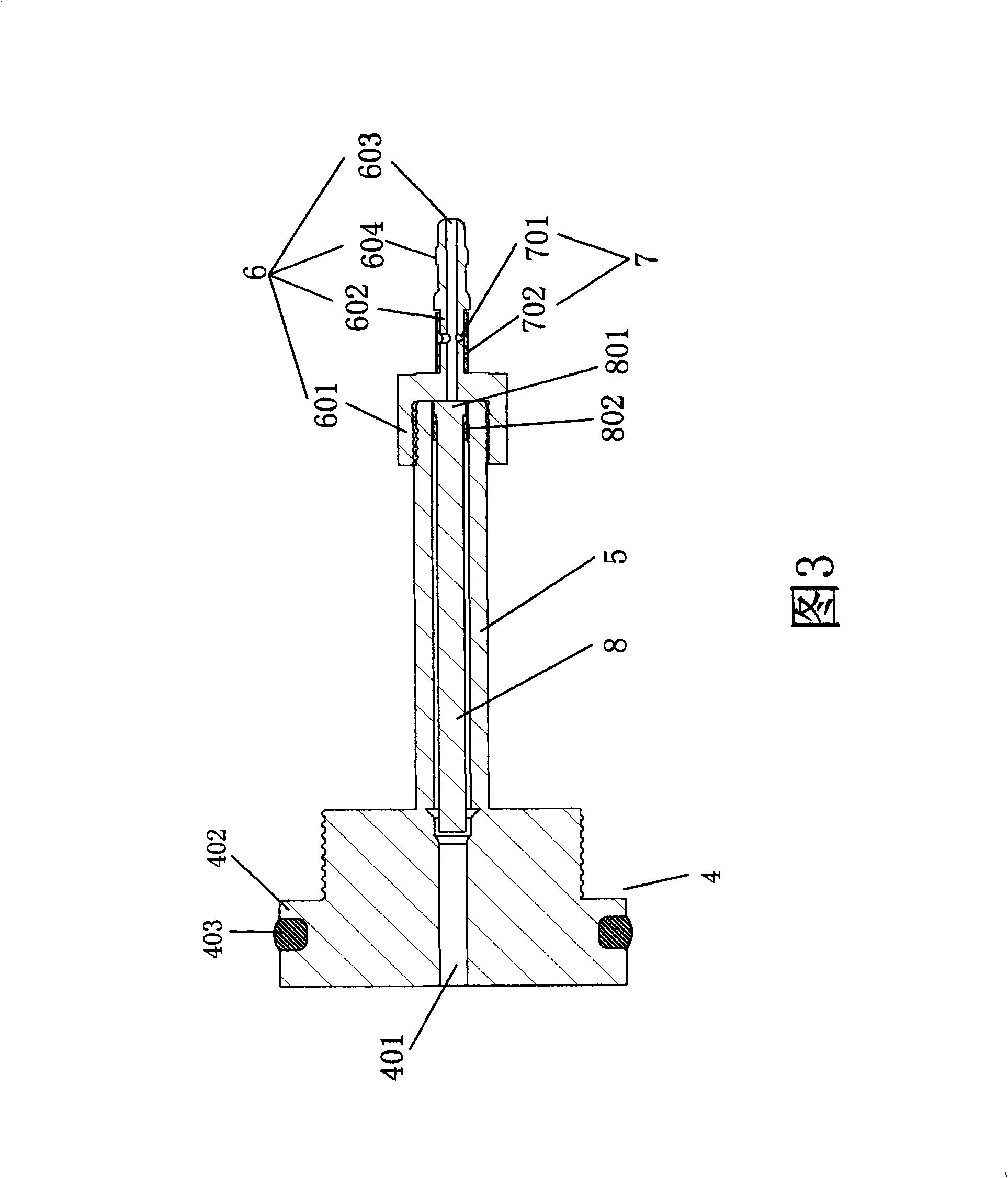

[0019] As shown in the figure, it includes air storage cylinder 1, air cylinder 2 and screw 3. The air storage cylinder 1 is inserted into the cavity of the air cylinder 2, and the screw 3 is set on the air storage cylinder 1 and screwed on the air chamber port of the air cylinder 2. The opening of the air storage cylinder 1 is screwed with a piston 4, the piston 4 is fixedly connected with an air pipe 5, and one end of the air pipe 5 is provided with a throttle valve 6 and a one-way valve 7, and a relevant air needle 8 is placed in the air pipe 5.

[0020] The gas closing needle 8, the throttle valve 6 and the one-way valve 7 are integrated, and the throttle tube 602 is extended from the connecting seat 601, and the related gas needle 8 is placed in the throttle tube 602, and the gas return hole 603 is arranged on the throttl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com