Internal tooth snap ring of fluid pipe connection apparatus

A technology of connecting device and internal tooth snap ring, which is applied in the direction of mechanical equipment, couplings, etc., can solve the problems that it is difficult to embed into the pipe wall, the depth of internal teeth embedded in the pipe wall cannot be controlled, and it is stuck into the pipe groove, so as to achieve good protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

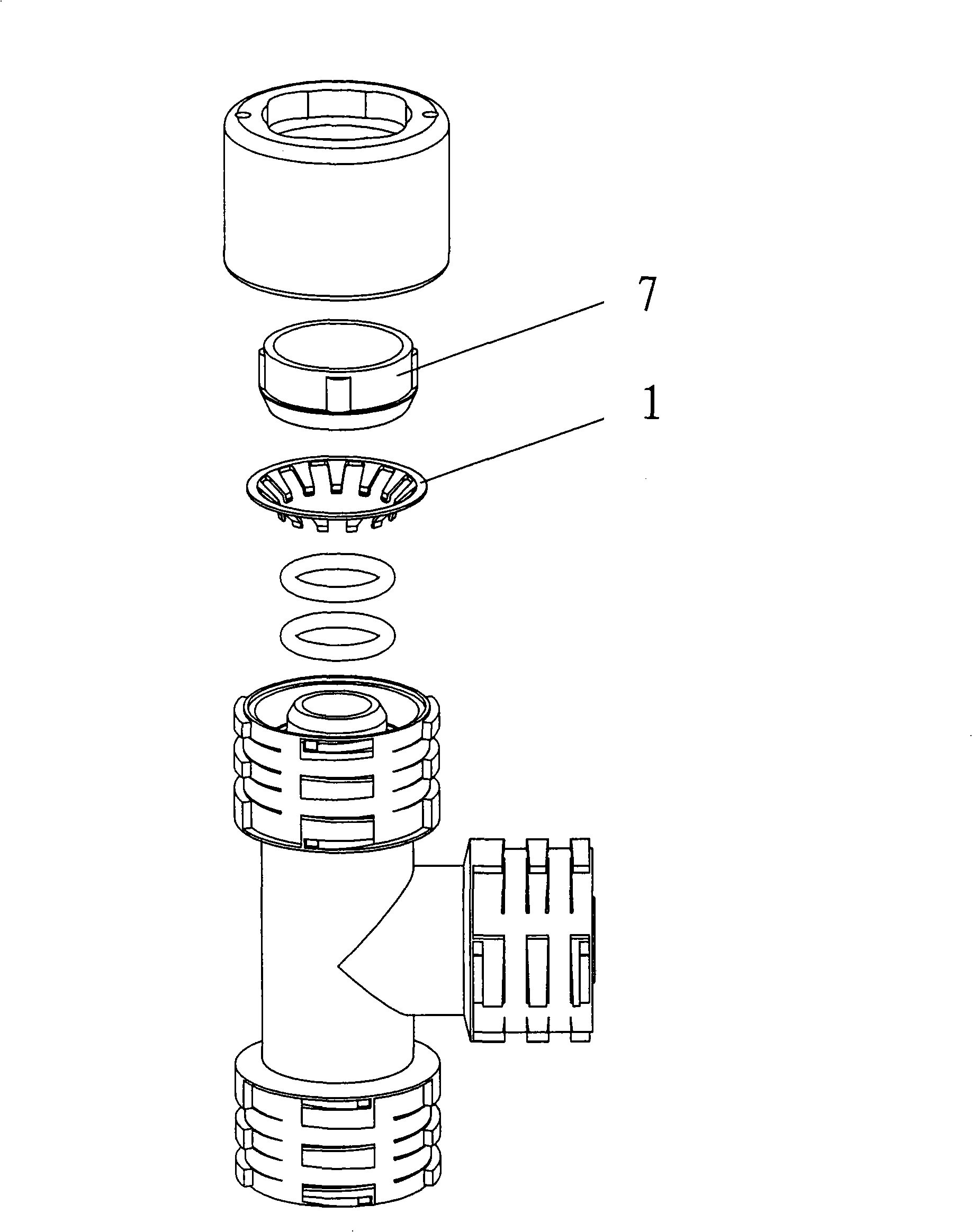

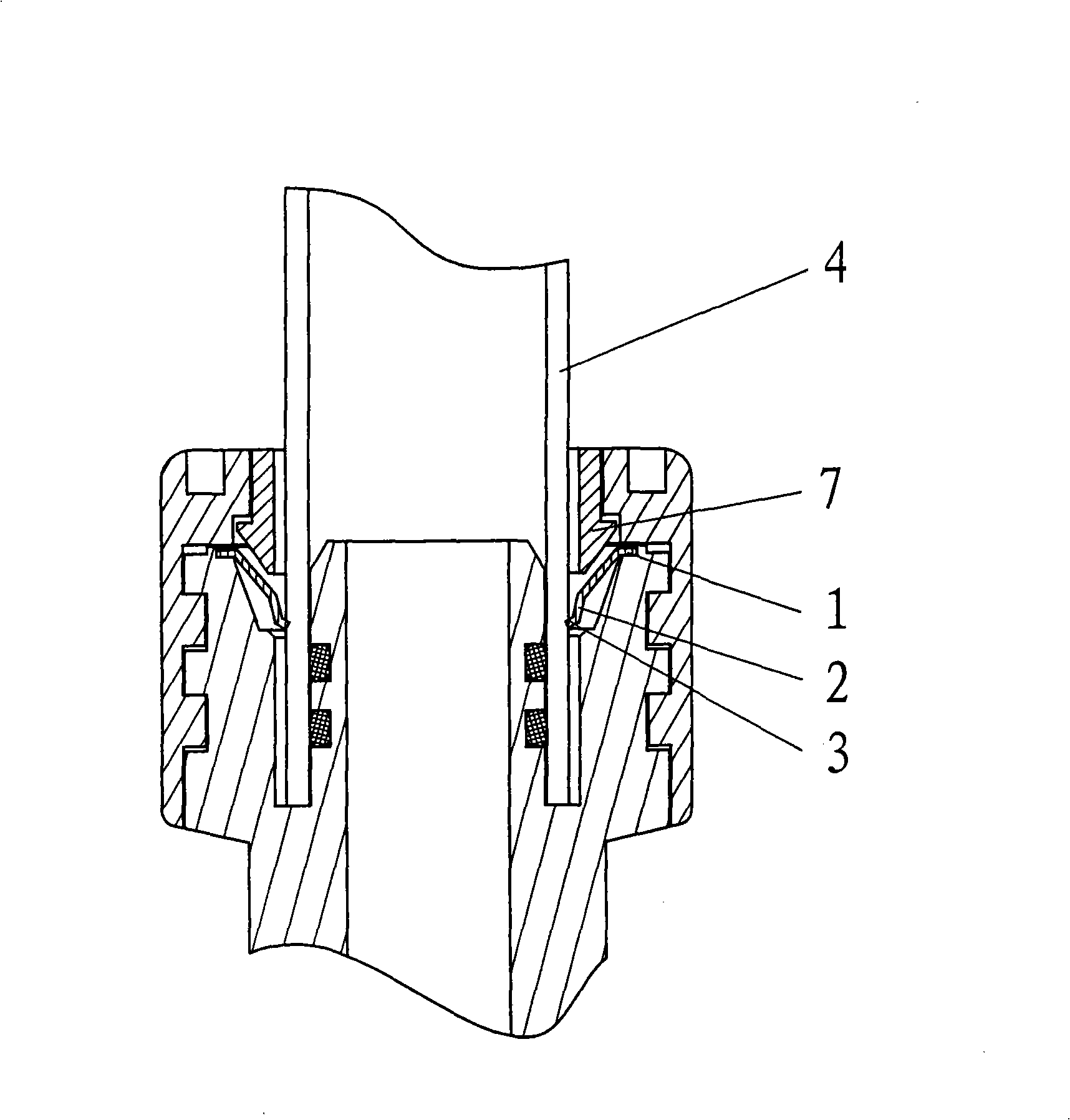

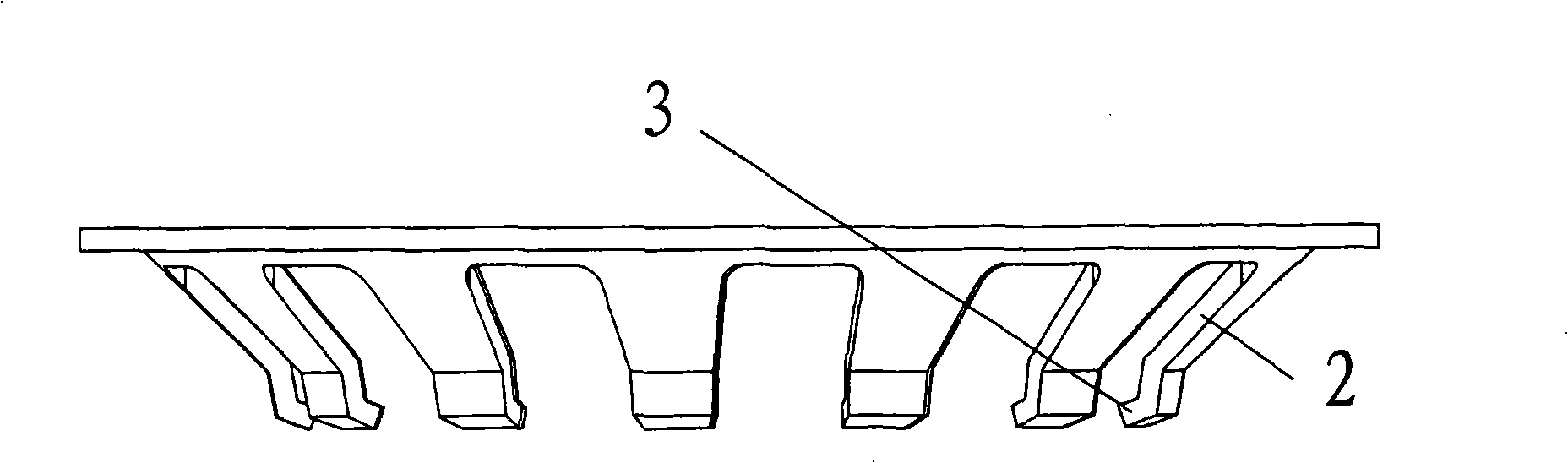

[0021] Such as figure 1 The fluid pipe connection device includes an internal tooth snap ring 1. After the fluid pipe connection is completed, if figure 2 As shown, the front end 3 of the internal teeth is embedded in the pipe wall 4, wherein the internal tooth snap ring 1 is as image 3 , 5 . The front end 3 of the inner tooth is bent toward the exit direction of the pipe, and the bent front end 3 of the inner tooth is about 2 mm long. The rear part 2 of the inner tooth protrudes toward the direction close to the pipe wall 4 .

[0022] In the docked state, the fluid flow in the pipeline causes the pipe wall 4 to be subjected to a force in the direction of the pipeline exit, and this force is transmitted to the rear part 2 of the inner tooth through the front end 3 of the inner tooth, so that the rear part 2 of the inner tooth is compressed and twisted. At this time, the inner tooth The rear part 2 of the tooth protrudes toward the direction close to the pipe wall 4, the...

Embodiment 2

[0024] Such as Figure 6 It is another internal tooth structure of the internal tooth snap ring of the present invention, and the front end 3 of the internal tooth is bent toward the exit direction of the pipeline. The rear part 2 of the inner teeth in this embodiment is basically in a straight line, which makes it difficult to push the inner teeth away by pushing the gear ring when removing the tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com