Drainage combined with sludge-cleaning vehicle sludge-water separating system

A mud-water separation and sewage cleaning vehicle technology, which is applied in dehydration/drying/concentrated sludge treatment, filtration separation, separation methods, etc., can solve the problems of complex structure, difficult and high cost of manufacturing, and difficulty in achieving long-term reliable work. Achieve the effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

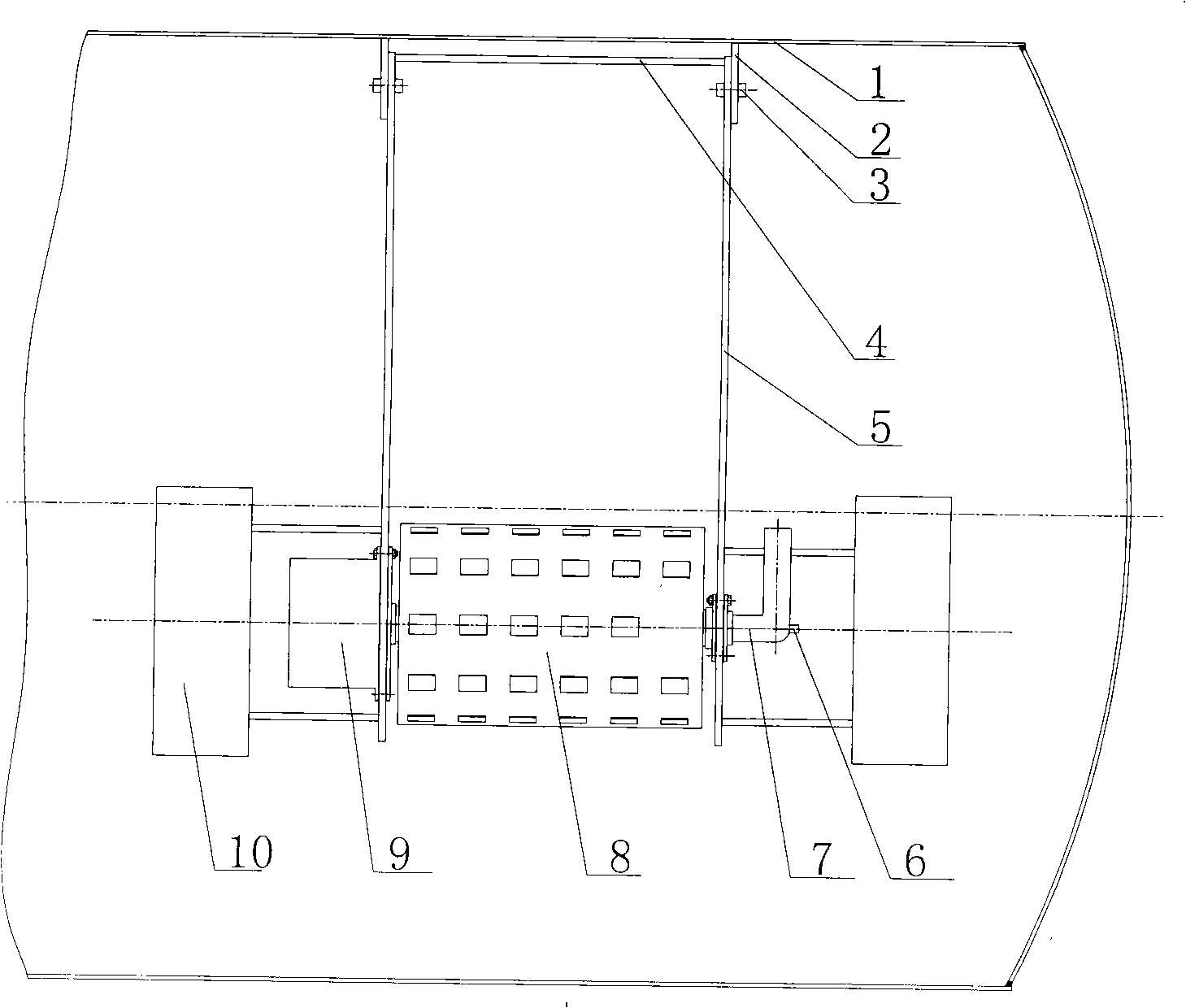

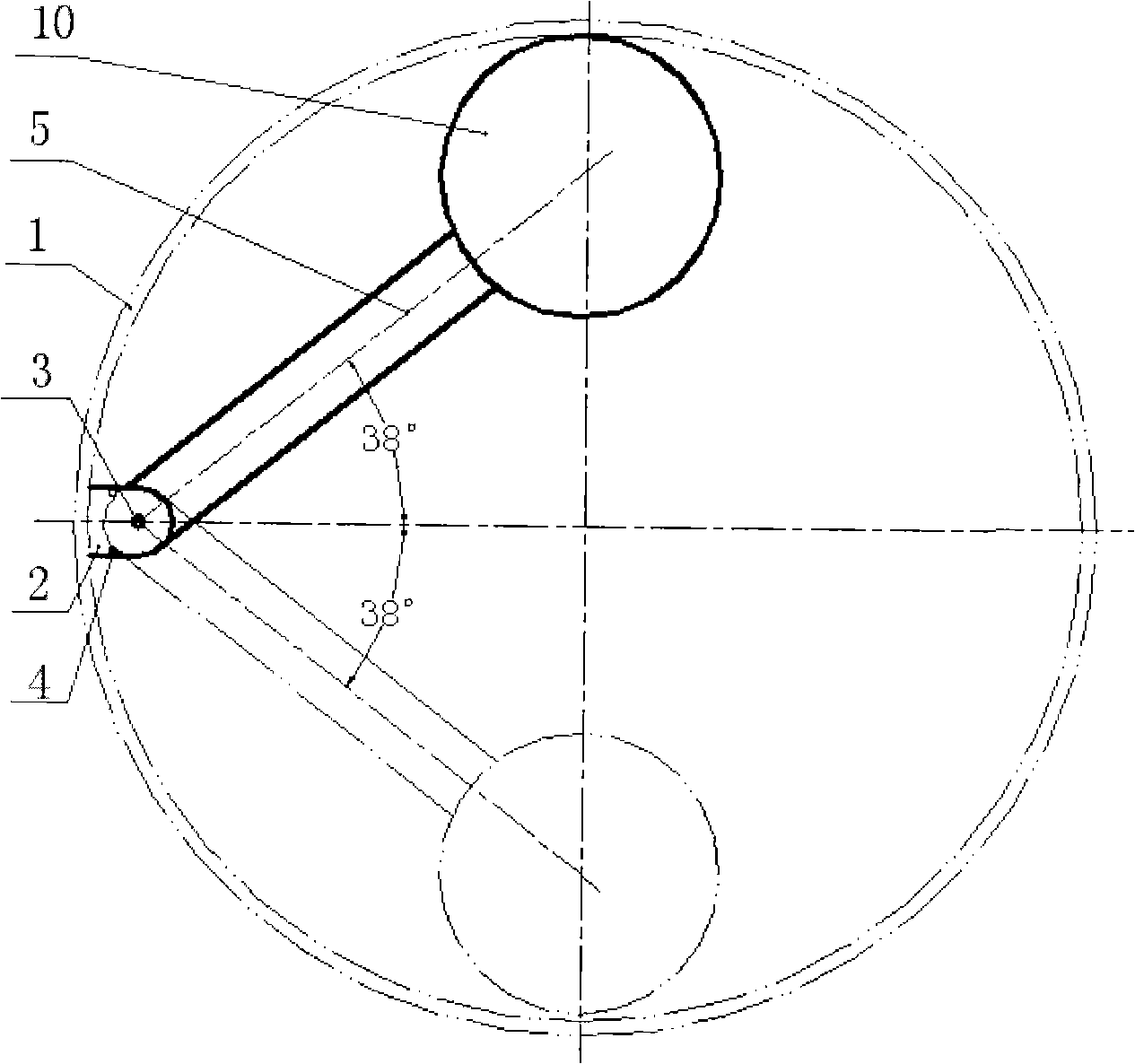

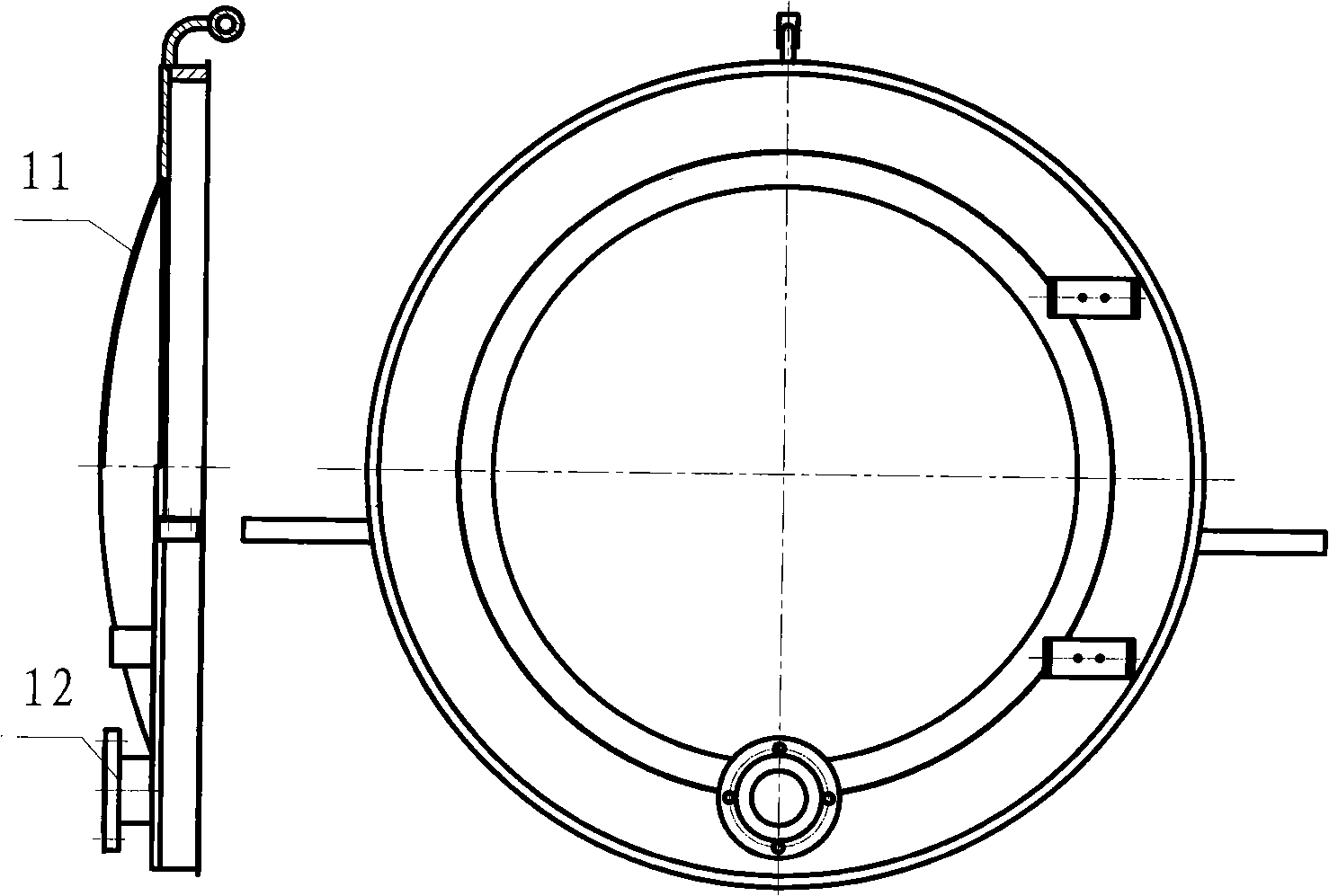

[0024] The structure of the sludge-water separation system of the sewer united cleaning vehicle of the present invention is as follows: Figure 4 shown. The system is mainly composed of a rotary filter cartridge 8, a bracket 5, a buoy 10, a sewage pump, a hydraulic motor 13, a backwash pipeline 6, a mud discharge valve 12, connecting pipes and various valves. The buoy 10 is coaxially installed at both ends of the rotating filter cartridge 8, and the journals at both ends of the rotating filter cartridge are respectively supported by deep groove ball bearing 14 and deep groove ball bearing 2 18 on the lower part of the bracket 5, and the upper part of the bracket 5 is passed through the hinge pin The shaft 3 is installed on the installation support 2 in the sludge tank 1. Under the buoyancy of the buoyancy drum 10, all the devices installed on the lower part of the support 5 are always suspended in the liquid, and the central axis of the rotating filter cartridge is always just ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com