Reflux-ratio temperature automatic control device and method of fractionating tower

A technology of automatic control device and reflux ratio, applied in the direction of distillation regulation/control, etc., can solve the problems affecting the quality requirements of the distillate at the top of the rectification tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

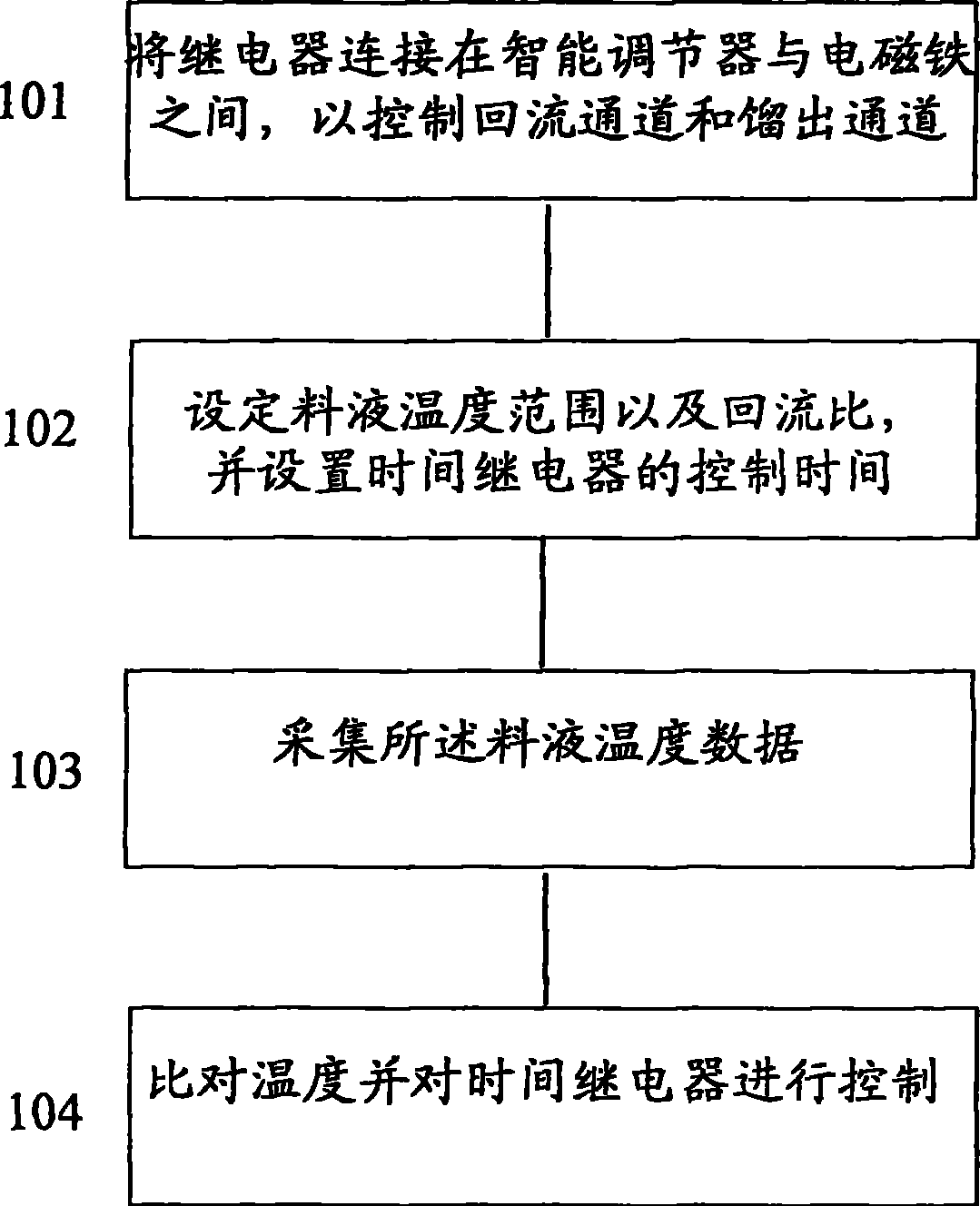

[0023] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

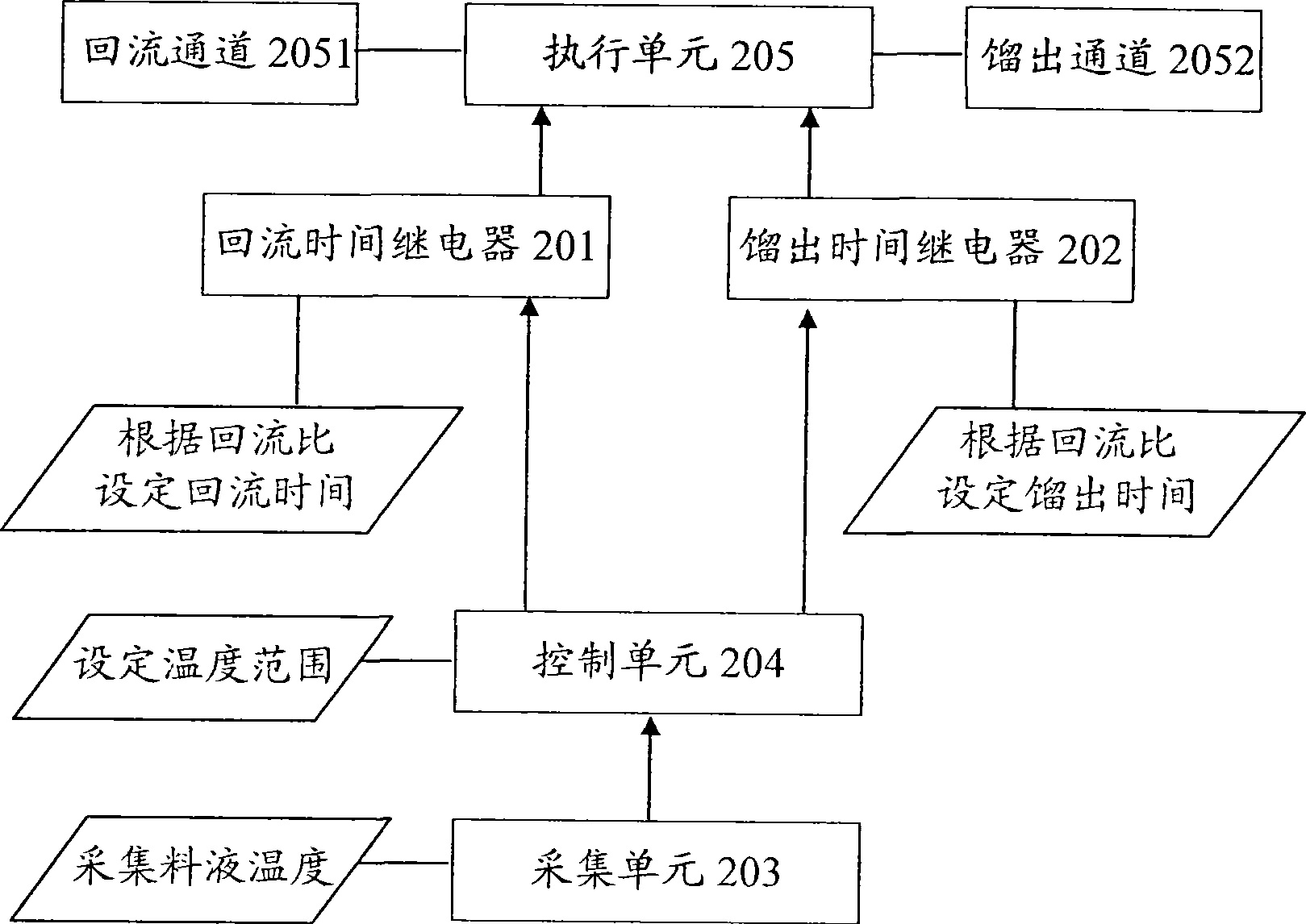

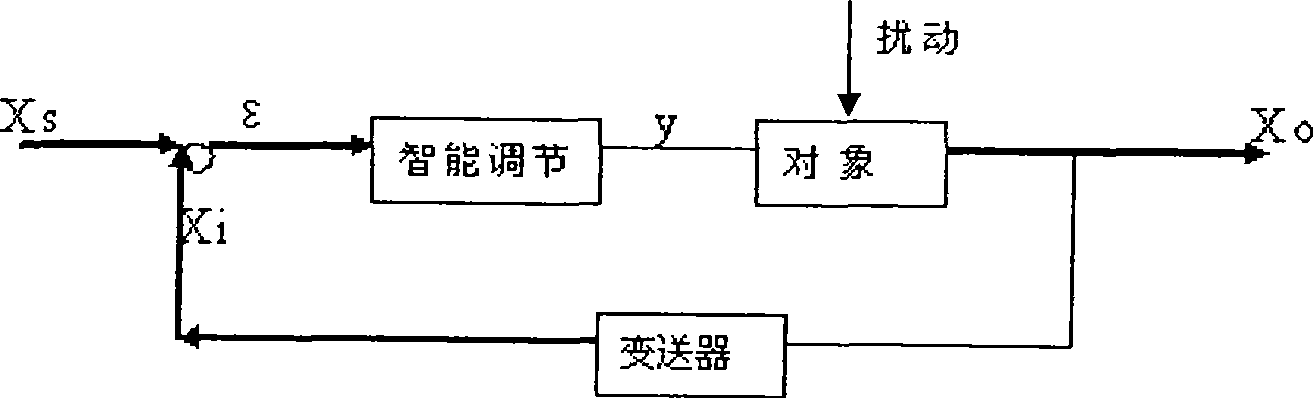

[0024] refer to figure 1 , on the one hand, the present invention is a kind of reflux ratio temperature automatic control device of rectification column, comprising:

[0025] The reflux time relay 201 is connected to the reflux passage 2051 of the rectification tower and controls its opening and closing. The distillation time relay 202 is connected to the distillation passage 2052 of the rectification tower and controls its opening and closing. The opening of the reflux passage 2051 means that the rectification The distillation column starts to reflux, and the opening of the distillation passage 2052 means that the distillation column has an output.

[0026] The collection unit 203 collects the feed liquid temperature data at the top of the rectification tower. The collection unit includes a temperature detector, and the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com