Method for preventing rebound of coil when iron core sheet inserting

A coil and iron core technology, applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, electrical components, etc., to achieve the effect of small iron cores and ample insertion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A method for preventing springback of coils when used for iron core insertion, characterized in that the method is:

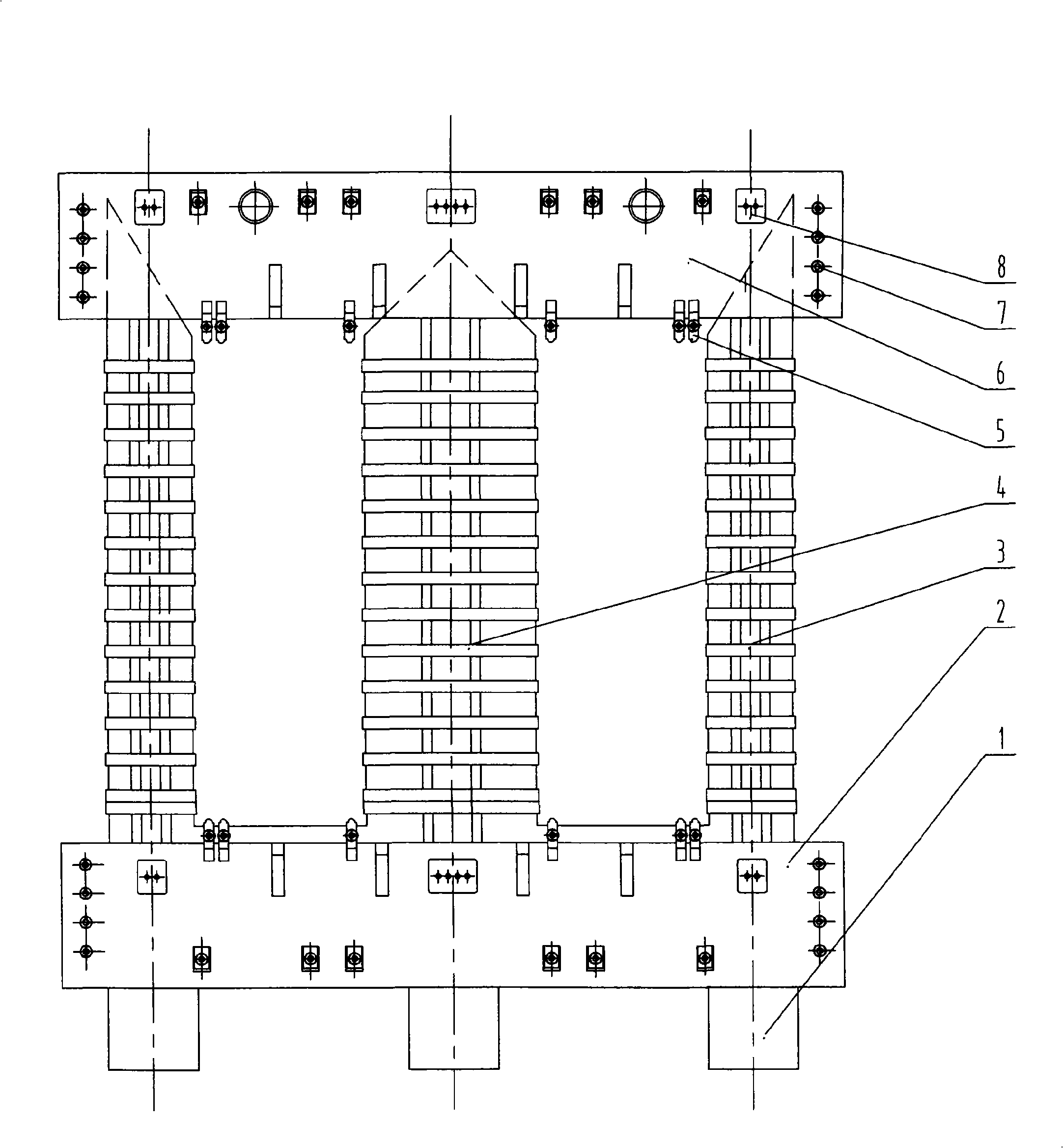

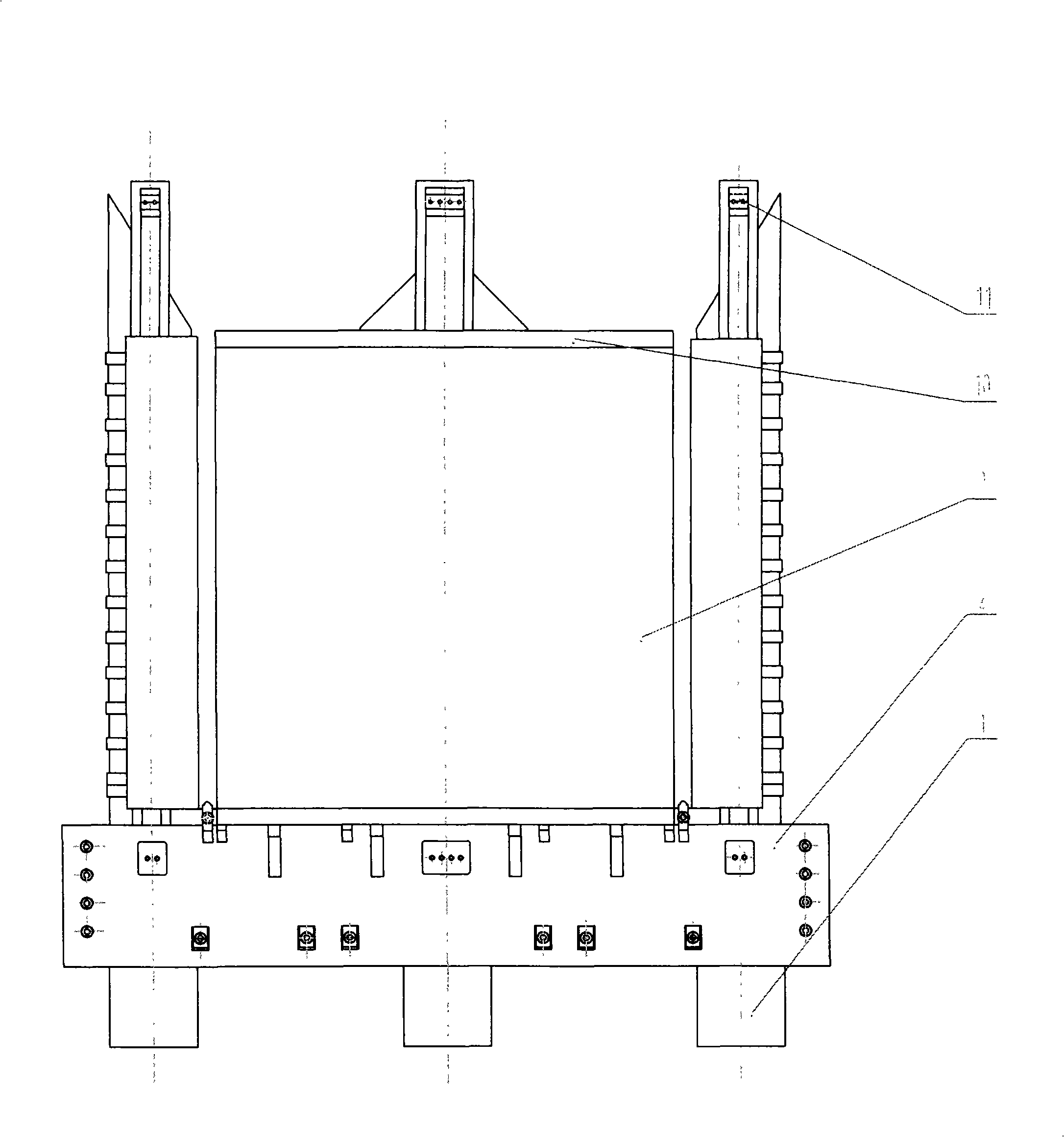

[0022] The first step. If figure 1 , 2 As shown, first put the iron core on the support iron 1 of length × width × height = 1400mm × 370mm × 340mm, and set the coil 9 on the iron core column 4;

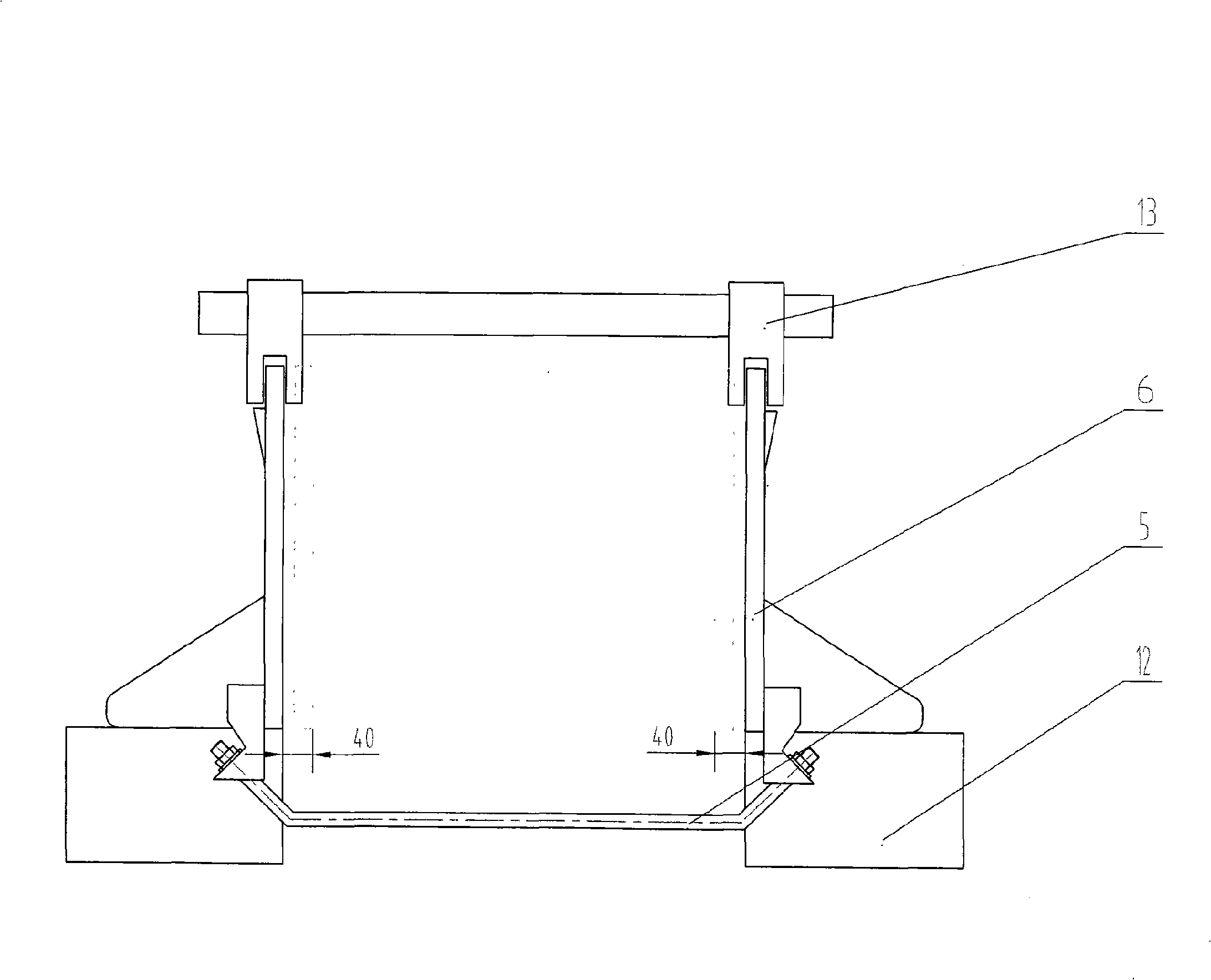

[0023] The second step. If image 3 As shown, the upper clamp 6 is fixed on the ground with the clamp fixing device 13, and the inner distance of the upper clamp 6 is enlarged by 80mm relative to the thickness of the upper iron yoke, so as to facilitate the insertion of the sheet, and the upper clamp 6 is made of laminated wood. After the block 12 is raised, install the pull screw 5 inside the iron yoke;

[0024] Step 3. Use the crane to lift the upper clamp 6 to the top of the body, gradually lower the crane hook, and after the pull plate head 11 is aligned with the pull plate hole 20 on the upper clamp web, drop the upper clamp 6. Put it on the coil to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com