Casing of electronic apparatus and manufacturing method thereof

A technology for electronic devices and manufacturing methods, applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, etc., can solve the problems that plastic shells cannot meet the rigidity requirements, and achieve the effect of meeting the rigidity requirements and avoiding wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

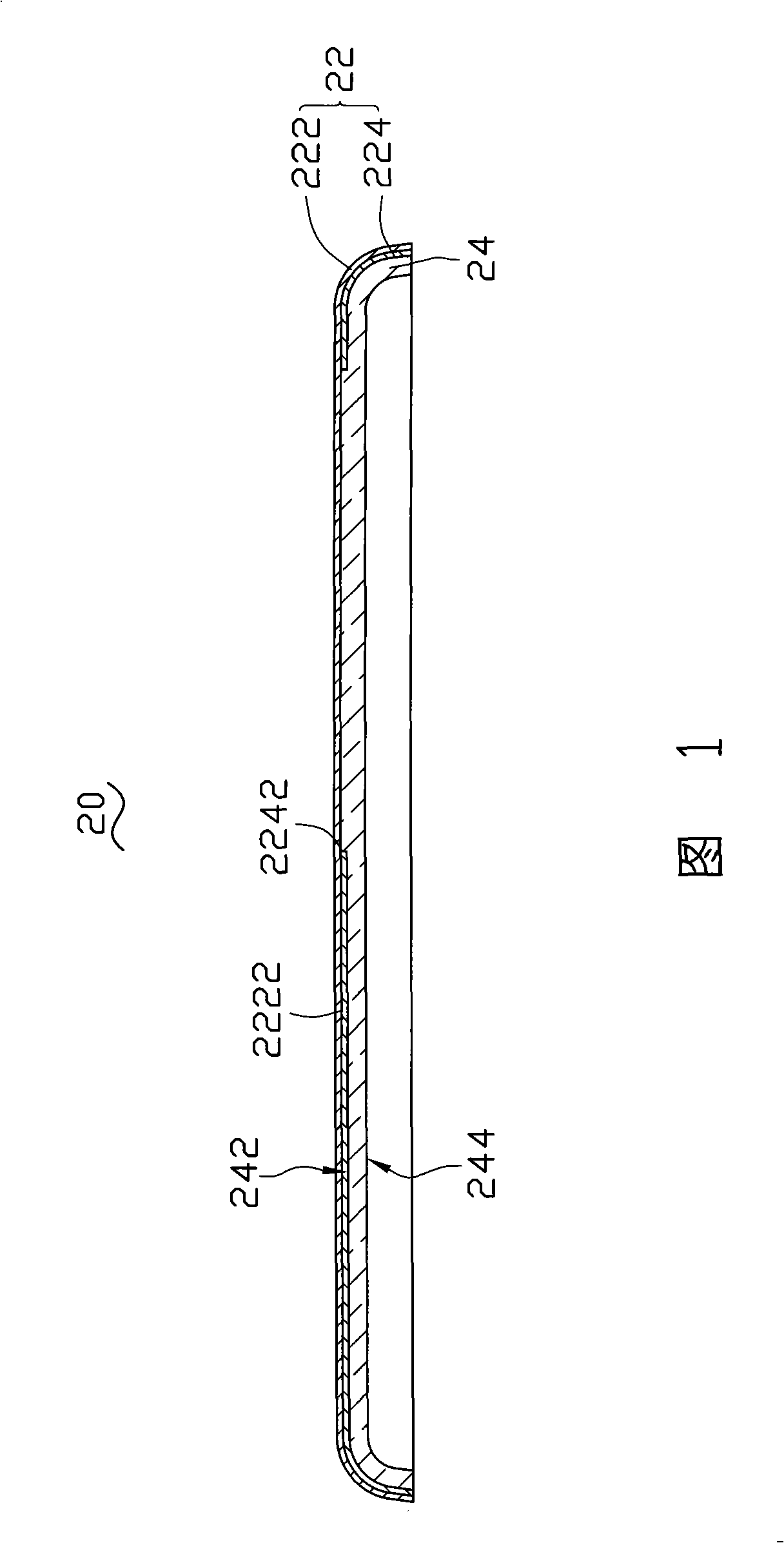

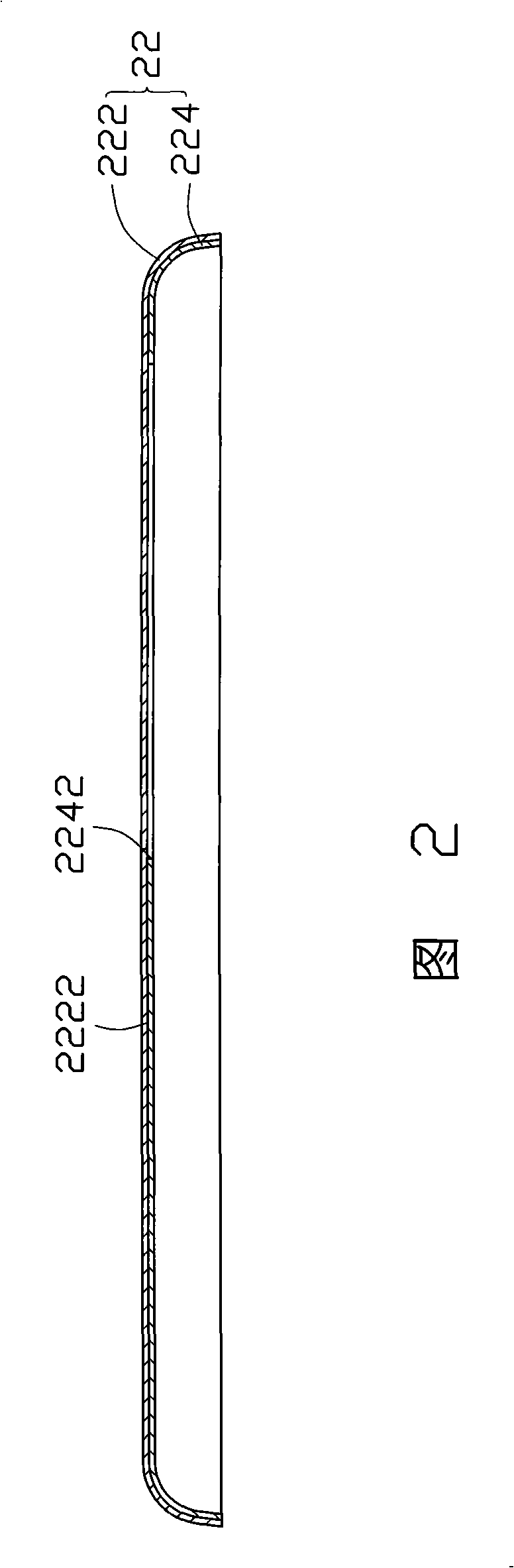

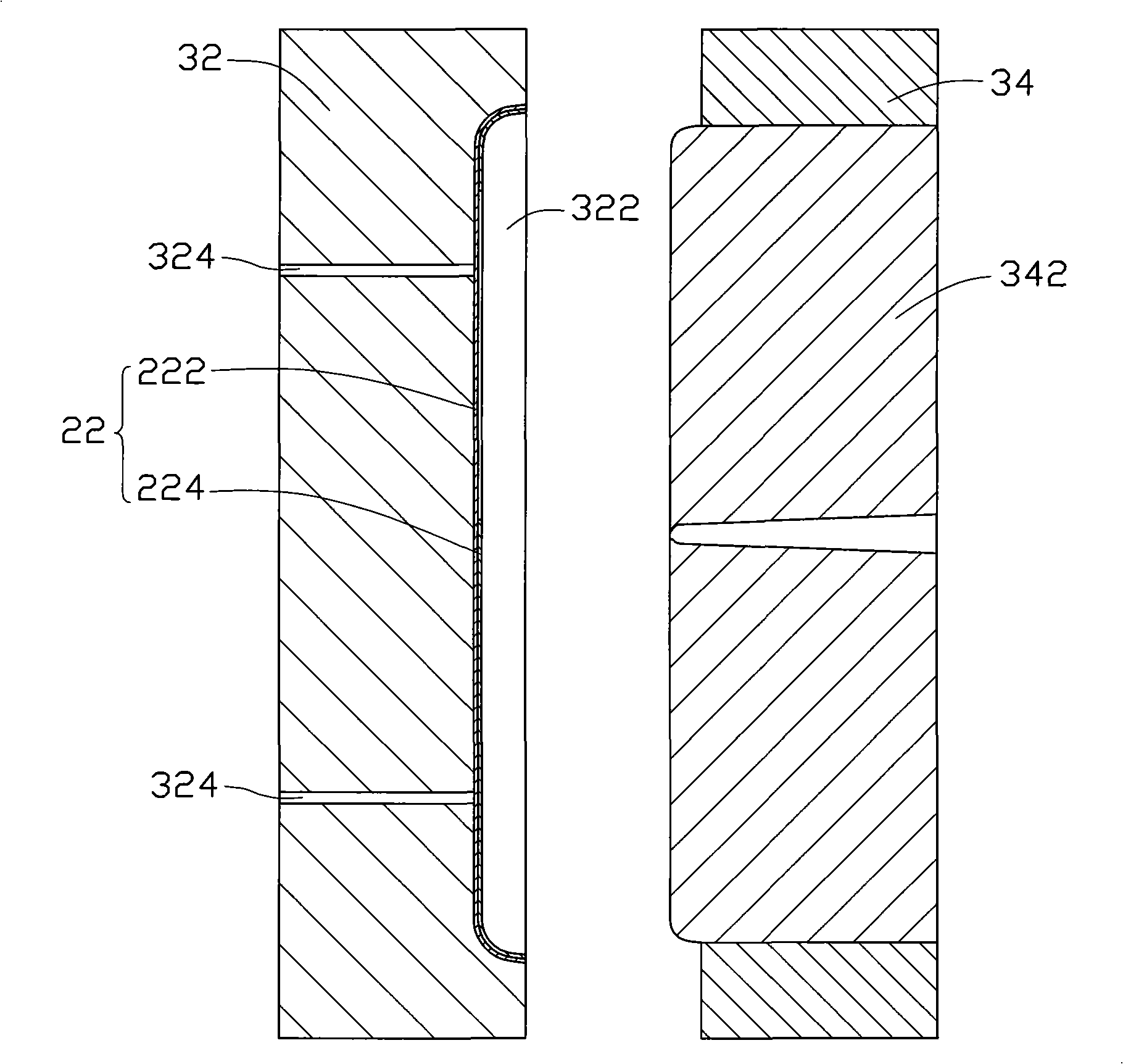

[0023] Please refer to FIG. 1 , which shows an electronic device casing 20 according to a preferred embodiment of the present invention. The electronic device casing 20 includes an insert layer 22 and a substrate 24 . The base body 24 includes an outer surface 242 and an inner surface 244 , the outer surface 242 is an appearance surface when the electronic device casing 20 is used, and the inner surface 244 is a surface opposite to the outer surface 242 . The insert layer 22 is disposed on the outer surface of the base body 24 , and the insert layer 22 and the base body 24 are integrally formed by in-mold injection.

[0024] The insert layer 22 includes a thin film layer 222 and a hard layer 224 , and the thin film layer 222 is formed on the hard layer 224 .

[0025] The hard layer 224 can be made of metal, glass or ceramics, and defines a through hole 2242 corresponding to the display window (not shown) of the electronic device using the electronic device housing 20 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com