A vibrating plate used in vibrating cotton feeder for hemp fiber spinning

A technology of vibrating disc and cotton feeder, applied in the direction of fiber opening and cleaning machine, etc., can solve the problems of low fiber hitting force, large gap between hemp fibers, affecting the uniformity of rolls, etc., and achieve the effect of improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

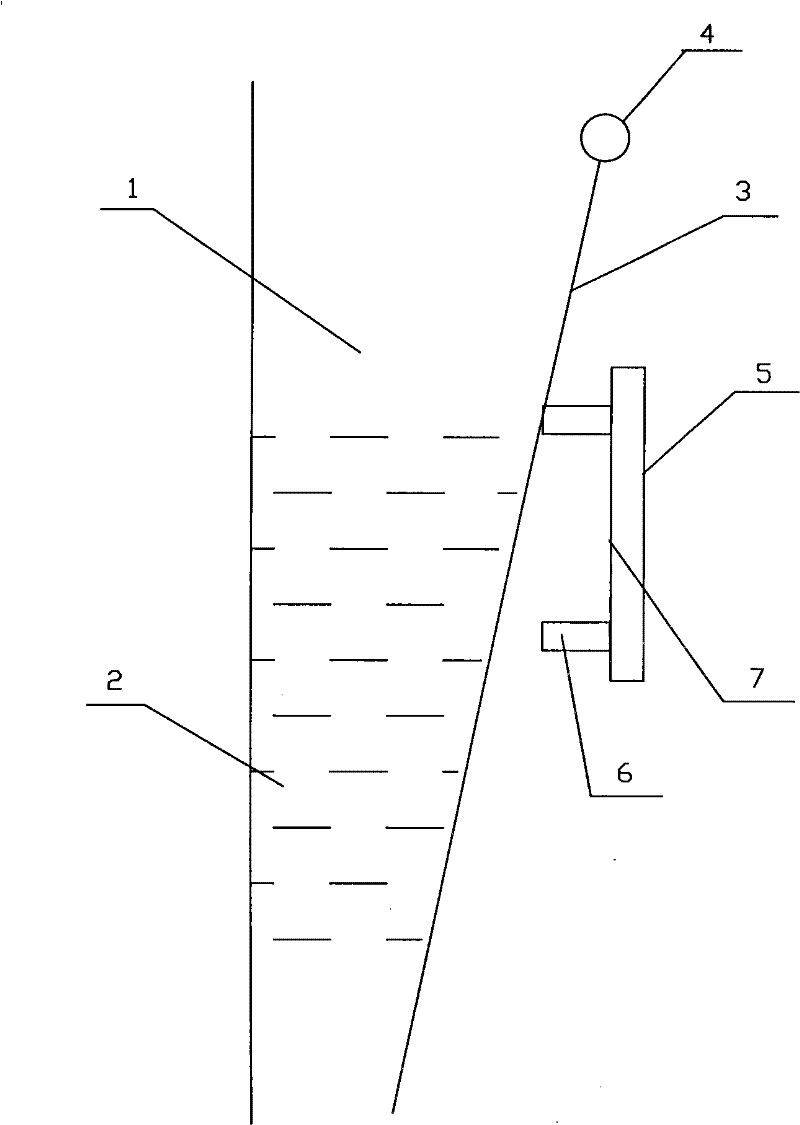

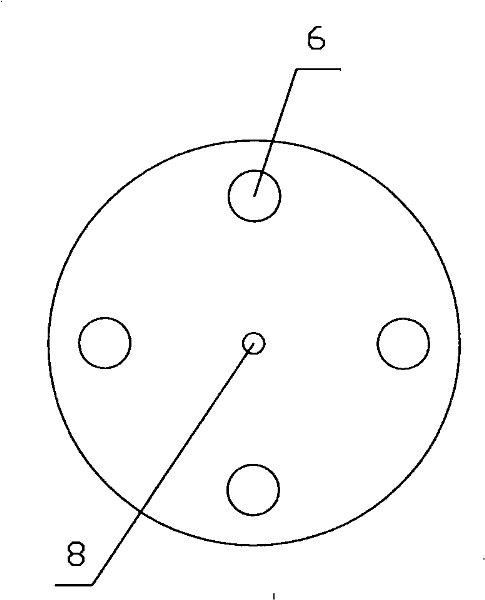

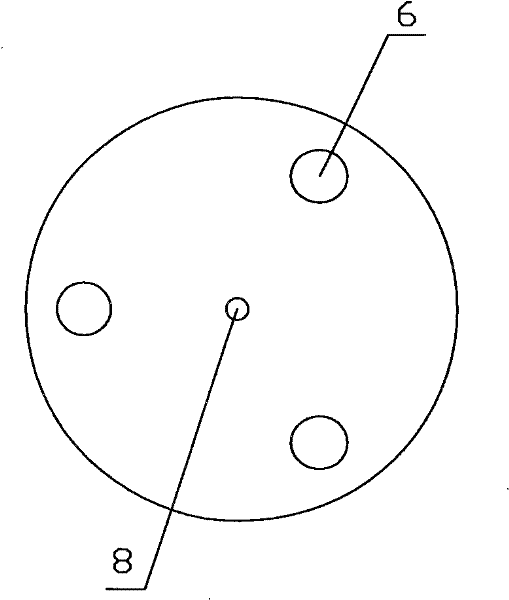

[0020] Such as figure 1 and figure 2 As shown, the vibrating plate used for the hemp fiber spinning vibrating cotton feeder of this embodiment includes a vibrating plate body 5 and 4 striking points 6 arranged on the working surface 7 of the vibrating plate body 5, the vibrating plate The working surface 7 of the main body 5 is circular, and the four striking points 6 are equally spaced and evenly distributed on the circumference concentric with the circular working surface 7, so that the impact on the vibrating cotton feeder is even and stable. When the vibrating disc body 5 rotated around its axis 8, the four striking points 6 on its working surface 7 contacted and hit the vibrating plate 3 of the vibrating cotton feeder in turn, and the vibrating plate 3 could therefore be controlled by gravity and the The vibrating plate body 5 swings around the fulcrum 4 under the joint action of the supporting force of each striking point 6, so that the striking force of the striking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com