Gas nailing tool

A tool and gas technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of narrowing the scope of use, complex manufacturing, increasing manufacturing costs, etc., and achieve the effects of low nailing cost, ingenious structural design, and simple manufacturing and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

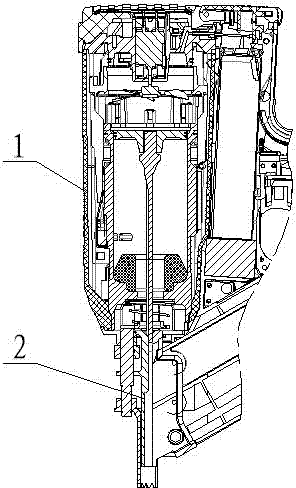

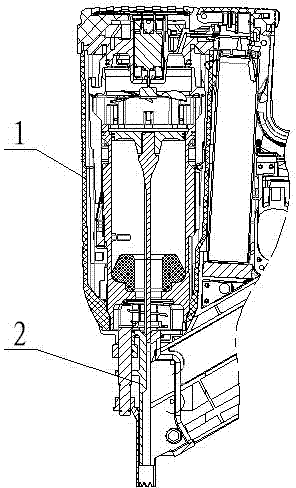

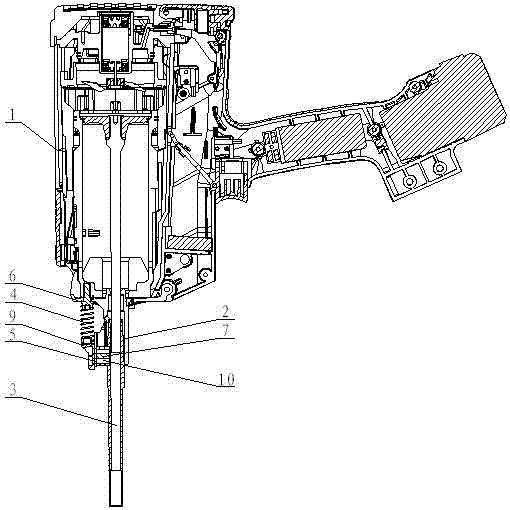

[0016] Embodiment 1: as image 3 , 4 As shown in , 5, a gas nailing tool includes a housing 1, a gun head 2, a gun barrel 3, a safety bracket clip spring 4 and a safety bracket 5, and the gun head 2 is connected to the front end of the housing 1 through a disc 6. connected, the gun head 2 and the gun barrel 3 are split, one end of the gun barrel 3 penetrates into the gun head 2 and is anti-rotated by the anti-rotation device, and the safety bracket clip spring 4 and the safety bracket 5 are connected to the the end.

[0017] Further description, the anti-rotation device is a boss 7 arranged on the outer wall of one end of the gun barrel 3 and an opening groove 8 arranged on the gun head 2, the boss 7 is located in the opening groove 8, and the safety frame One end of stage clip 4 is connected with boss 7 by spring seat 9 and screw 10, and the other end is connected with disc 6, and the bottom of described safety bracket 5 is positioned between spring seat 9 and boss 7, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com