Shot blasting spray gun

A spray gun and shot peening technology, applied in the directions of spray guns, explosion generating devices, abrasives, etc., can solve problems such as unfavorable access to rubber pipes, affecting air jet strength, and lack of smooth transition zone, and achieves good surface treatment effect and increase. The effect of large effective jetting force and surface roughness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

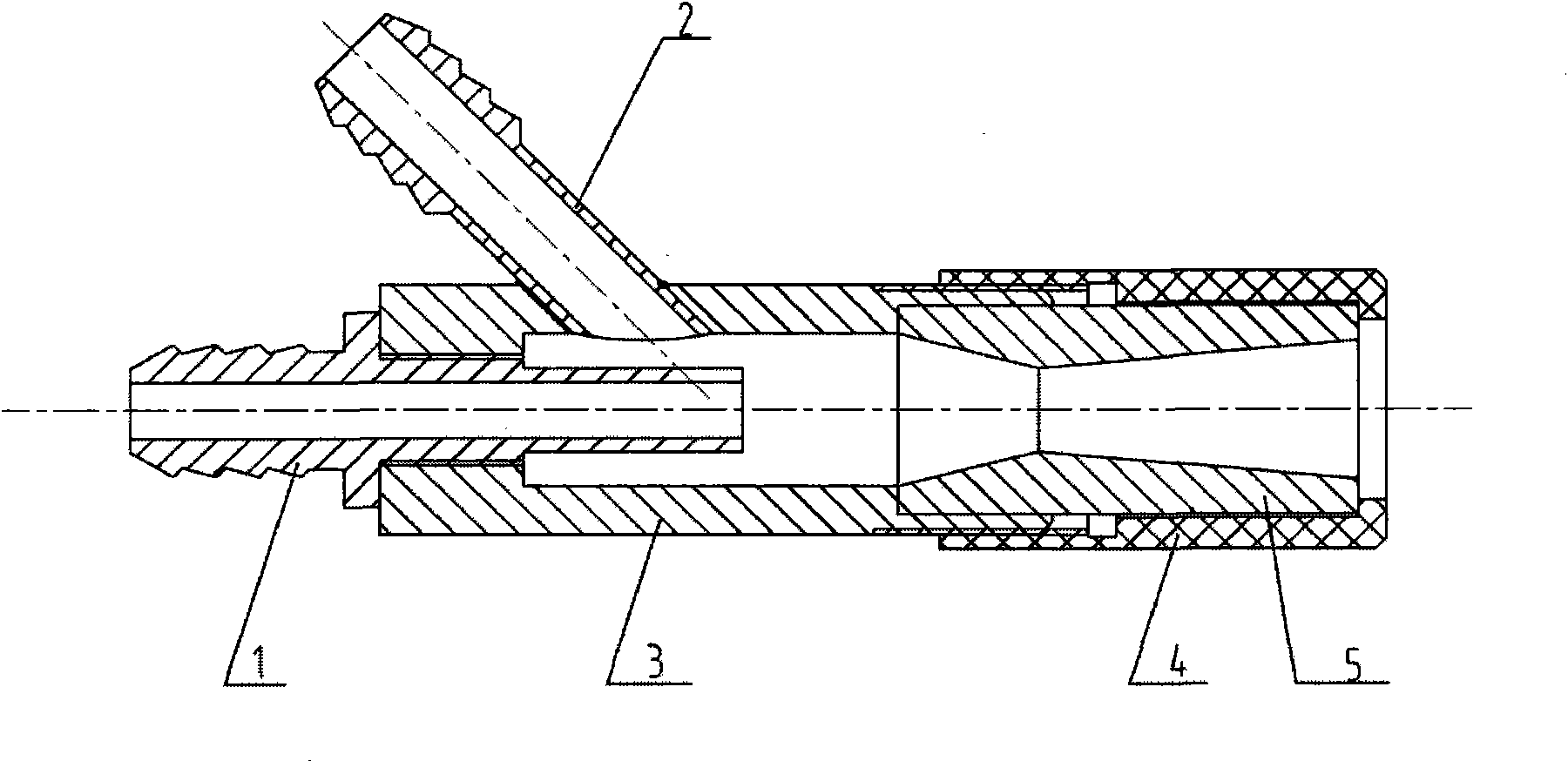

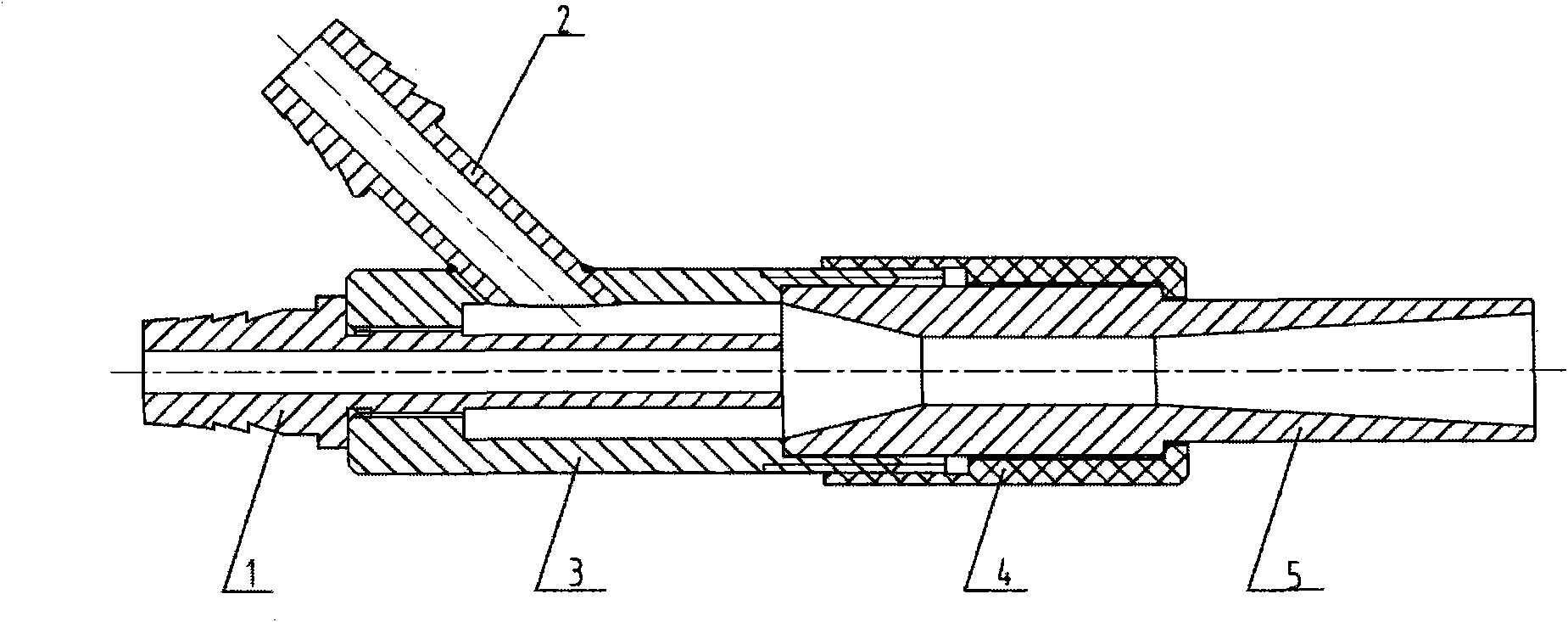

[0030] Specific embodiments of the present invention will be described below with reference to the drawings.

[0031] like figure 2 , the present invention includes: a main body, a mixing chamber 3 located in the main body, an air inlet pipe 1, a projectile inlet pipe 2, a sleeve 4, and a nozzle 5. The extension area that enters the main body of the air inlet pipe 1 is shaped on an external thread, and the corresponding part of the inner hole of the mixing chamber 3 in the main body is equipped with an internal thread, and the two are connected by threads.

[0032] The mixing chamber is approximately cylindrical and has a front end, a rear end and a side wall, each of which is provided with an opening, and the opening of the side wall communicates with an oblique cylindrical hole on the main body, and the projectile inlet pipe 2 is welded in oblique cylindrical holes.

[0033] The end that projectile enters pipe 2 stretches into does not protrude mixing chamber 3 inner surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com