Cryogenic fluid electromagnetic valve

A low-temperature fluid and solenoid valve technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve problems such as leakage and unreliable work, and achieve the effects of reliable work, convenient processing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

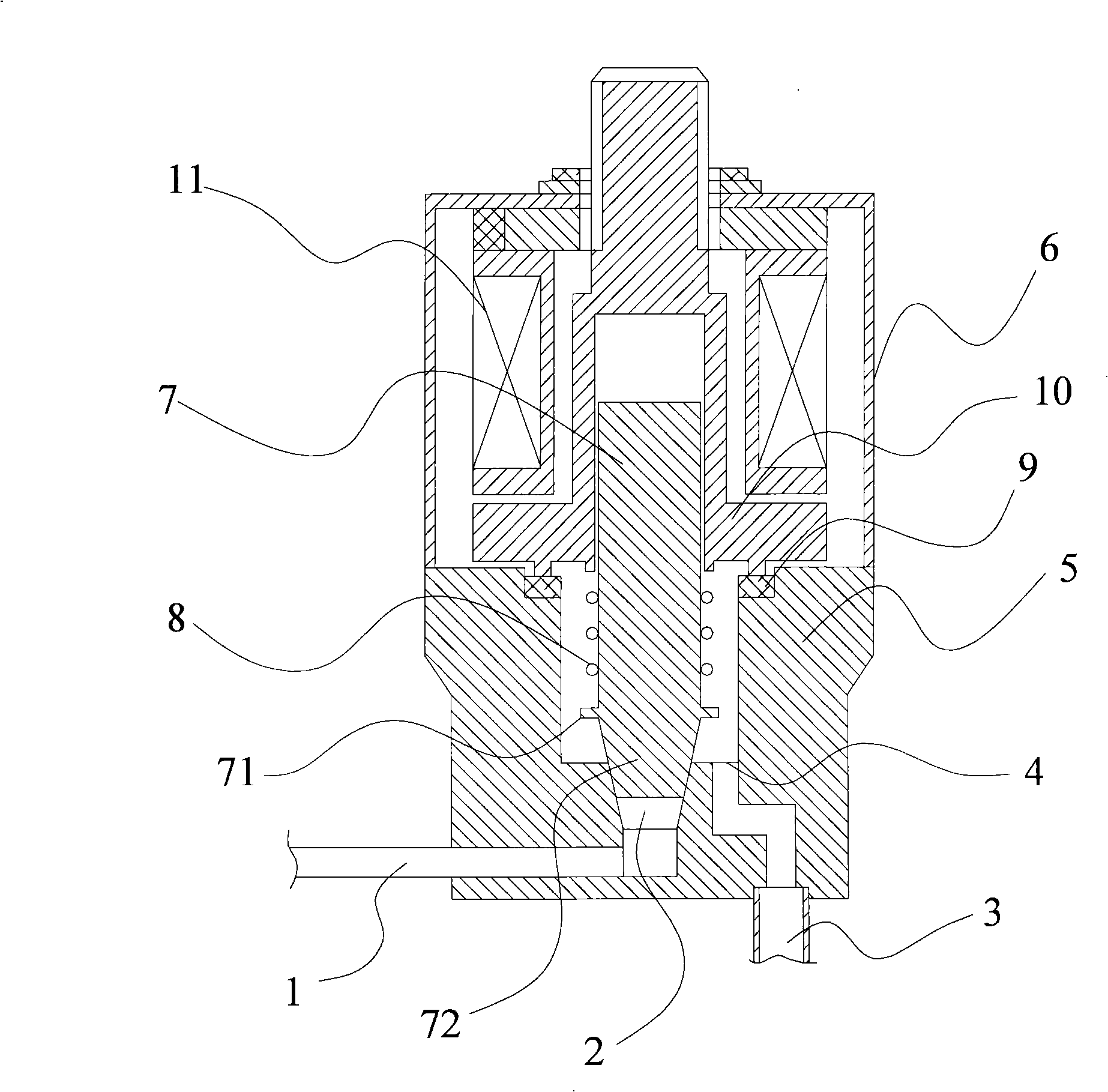

[0014] Such as figure 1 The low-temperature fluid solenoid valve shown includes a valve seat 5 and a valve cover 6 covering the valve seat. The valve cover 6 is provided with a coil seat 10, and a sealing ring 9 is placed between the coil seat 10 and the valve seat 5. The sealing ring 9 can be made of materials such as plastics and rubber. A coil 11 is wound around the coil seat 10, and a lifting chamber is arranged in the coil seat 10, and a valve core 7 is housed in the lifting chamber.

[0015] Spool 7 can use Cr 13 Al 4 Made of Nb magnetic stainless steel, a protruding ring 71 is arranged on it, and a spring 8 is sleeved between the protruding ring 71 and the coil seat 10 . The lower end of the valve core 7 is a rounded frustum-shaped sealing portion 72, and a circular liquid outlet 2 is opened at a corresponding position on the valve seat 5. The diameter of the liquid outlet 2 is larger than the diameter of the lower end of the rounded frustum-shaped sealing portion 72...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com