Backlight system and microstructure reflector plate

A backlight system and micro-reflection technology, applied in reflectors, light guides of lighting systems, optics, etc., can solve the problems of high manufacturing cost, large number of backlight system components, and low light utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

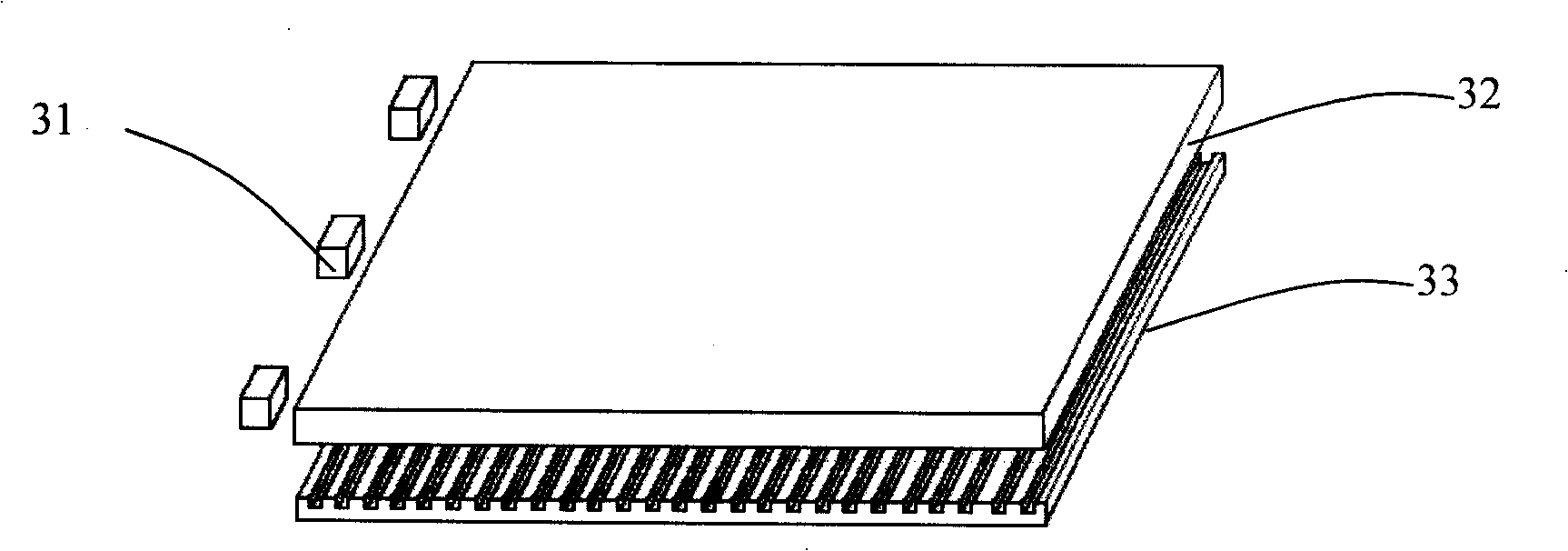

[0026] Such as image 3 as shown, image 3 It is a structural schematic diagram of an embodiment of the backlight system of the present invention. The backlight system of this embodiment includes: a light source 31 , a light guide plate 32 and a reflection sheet 33 . Wherein, the light guide plate 32 includes a light incident surface for receiving light from the light source 31 , a light exit surface for emitting light, and a bottom surface opposite to the light exit surface. The shape of the light guide plate 32 can be flat, wedge-shaped or other appropriate shapes, the thickness is usually 0.1mm-50mm, and the material is selected from light-transmitting materials, usually acrylic resin or polycarbonate resin, preferably with a refractive index of 1.49 polymethyl methacrylate (PMMA). The light source 31 can be a well-known LED light source, cold cathode fluorescent tube or other suitable light source, and is arranged near the light incident surface of the light guide plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap