Apparatus and method for cleaning of objects, in particular of thin discs

A technology of equipment and equipment pairs, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the influence of processing process, can not guarantee the quality of surface performance, can not guarantee standardized and reproducible results, etc. problem, to achieve the effect of uniform flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

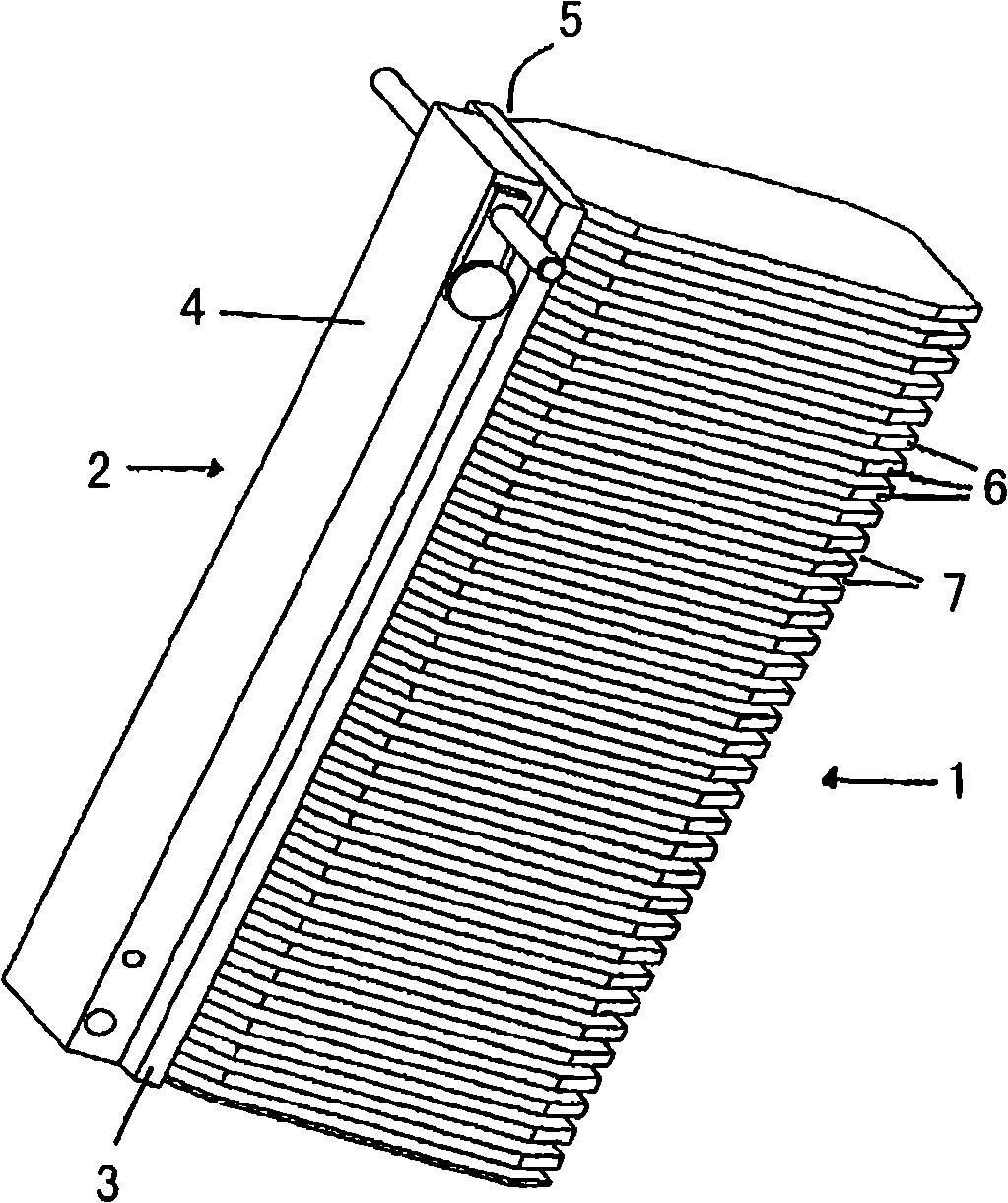

[0046] figure 1 A substrate piece 1 to be cleaned is shown. The substrate block 1 is arranged on a support device 2 , which in turn comprises a glass pane 3 and fastening elements 4 . In the exemplary embodiment shown here, the substrate block 1 is adhered to the glass pane 3 with one side 5 in a planar manner. The cutouts of the already performed sawing process extend into the glass pane 3 , by means of which individual substrates are produced, which are also referred to as wafers 6 . Interspaces 7 are produced between the individual wafers 6 in each case, in which there is a so-called mortar (not shown in the drawing) which is to be removed by the cleaning process according to the invention.

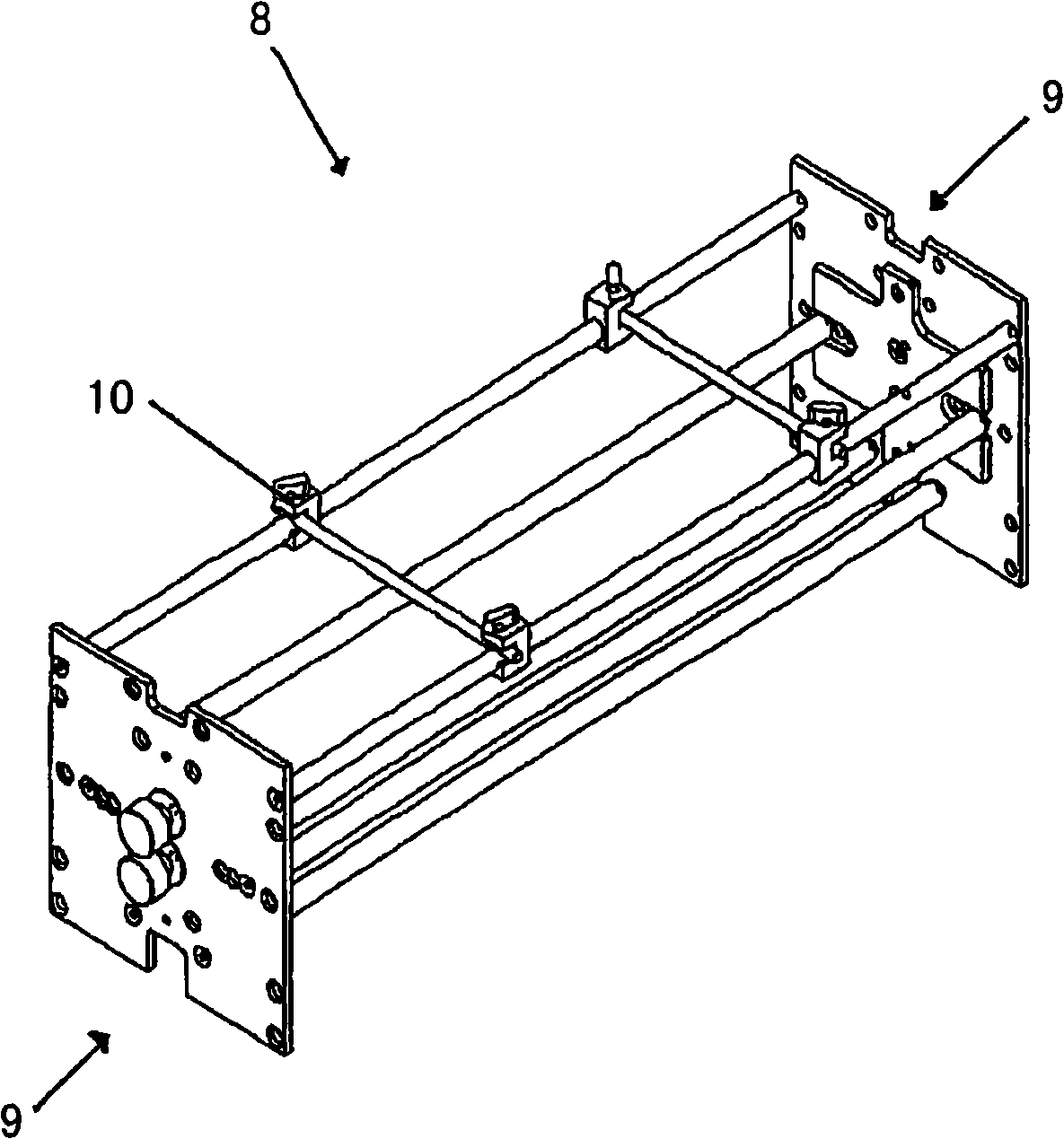

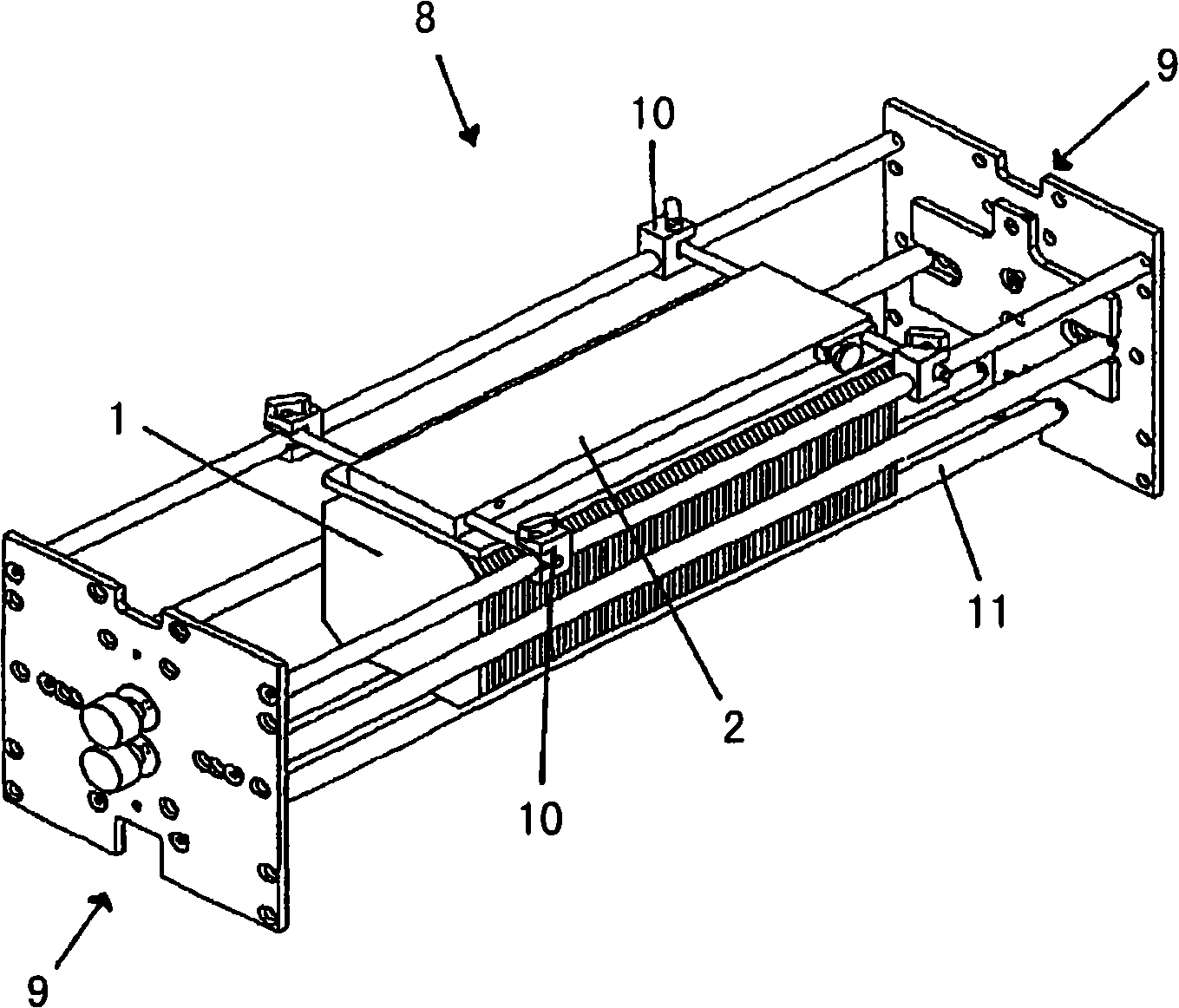

[0047] In order to be able to hand over the substrate block 1 connected to the support device 2 to the device according to the invention as in Figure 4 and the equipment shown in 5, handing over the stand device 2 as in figure 2 and 3 Auxiliary device 8 shown in. The auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com