Amortization connecting nut

A technology for connecting nuts and nuts, applied in the direction of nuts, connecting components, threaded fasteners, etc., can solve the problems of scrapping of connected plastic parts, inconvenient operation, difficult connection, etc., to achieve quick connection operation, improve reliability, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

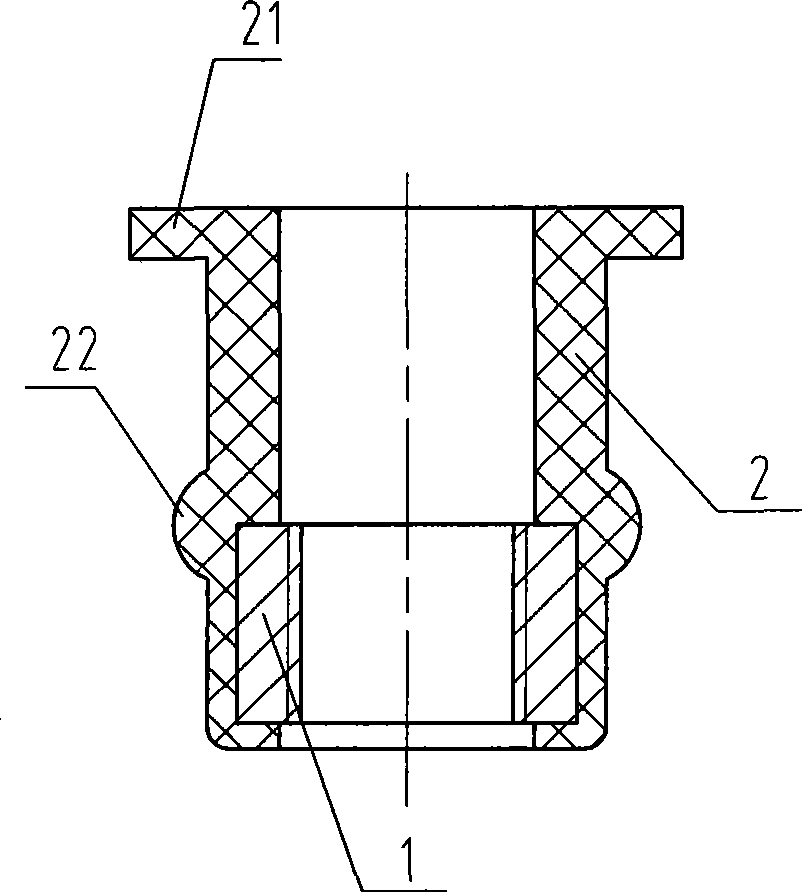

[0015] Such as figure 1 As shown, the nut 1 is integrally embedded in the inner hole of one end of the buffer bush 2, the other end of the buffer bush 2 is provided with a radially outward boss 21, and the outer wall of the buffer bush is provided with an annular protrusion twenty two.

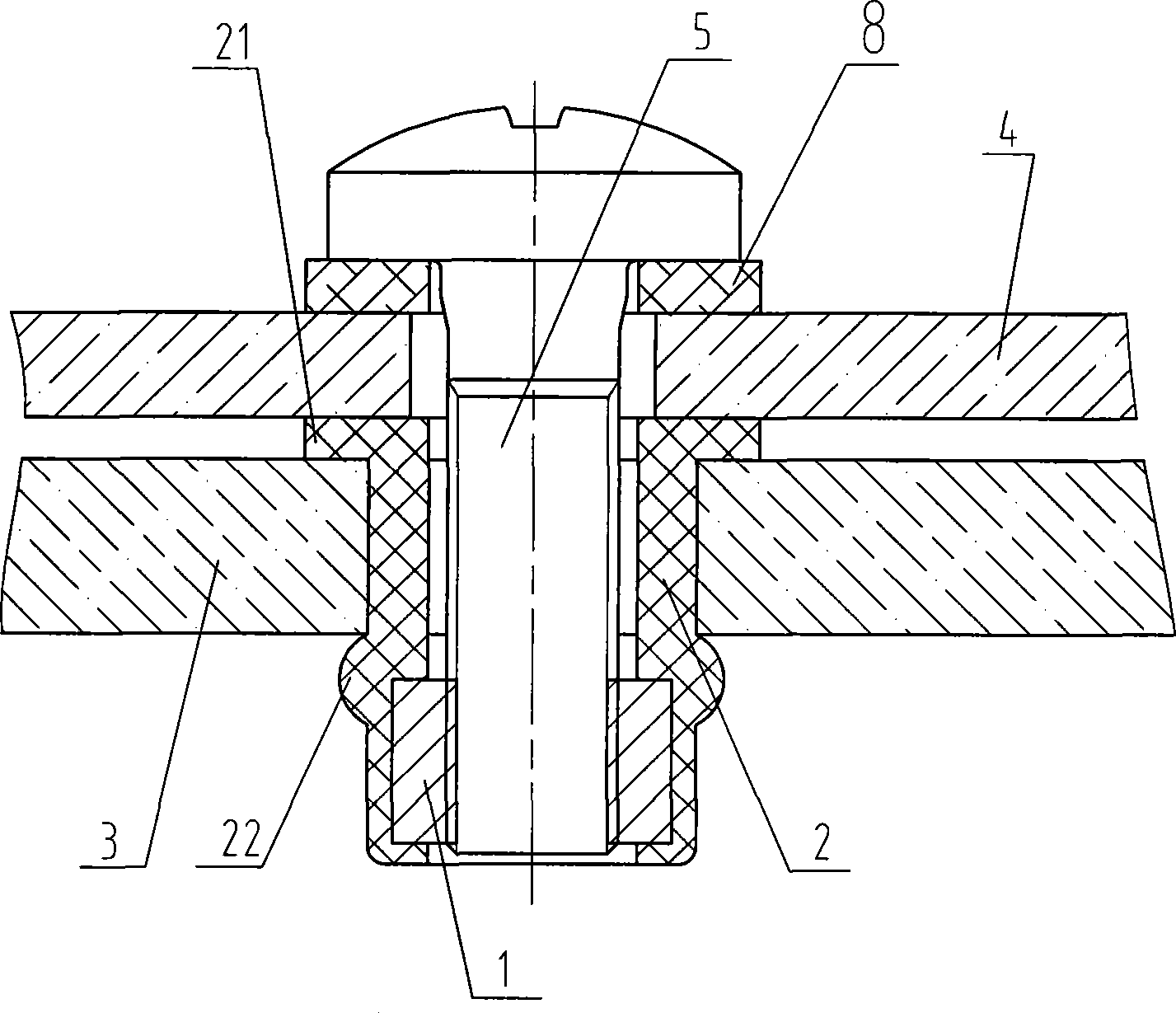

[0016] see figure 2 , when assembling and connecting, first install the buffer bushing 2 in the bolt hole of the first connecting piece 3, so that the first connecting piece 3 is limited between the boss 21 and the annular protrusion 22, and the end of the buffering bushing 2 The boss 21 and the surface of the first connecting piece 3 are well bonded, and then the bolt holes of the second connecting piece 4 are aligned with the inner holes of the buffer bushing 2 and fit together, and finally the screw 5 is screwed on, and the whole process does not need to use The nut is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com