Device for comminuting all types of parts

A technology for crushing equipment and components, applied in the field of crushing equipment for plastic hollow bodies and plastic bottles, can solve the problems of reduction, loud emission, and difficulty in inputting materials to be crushed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

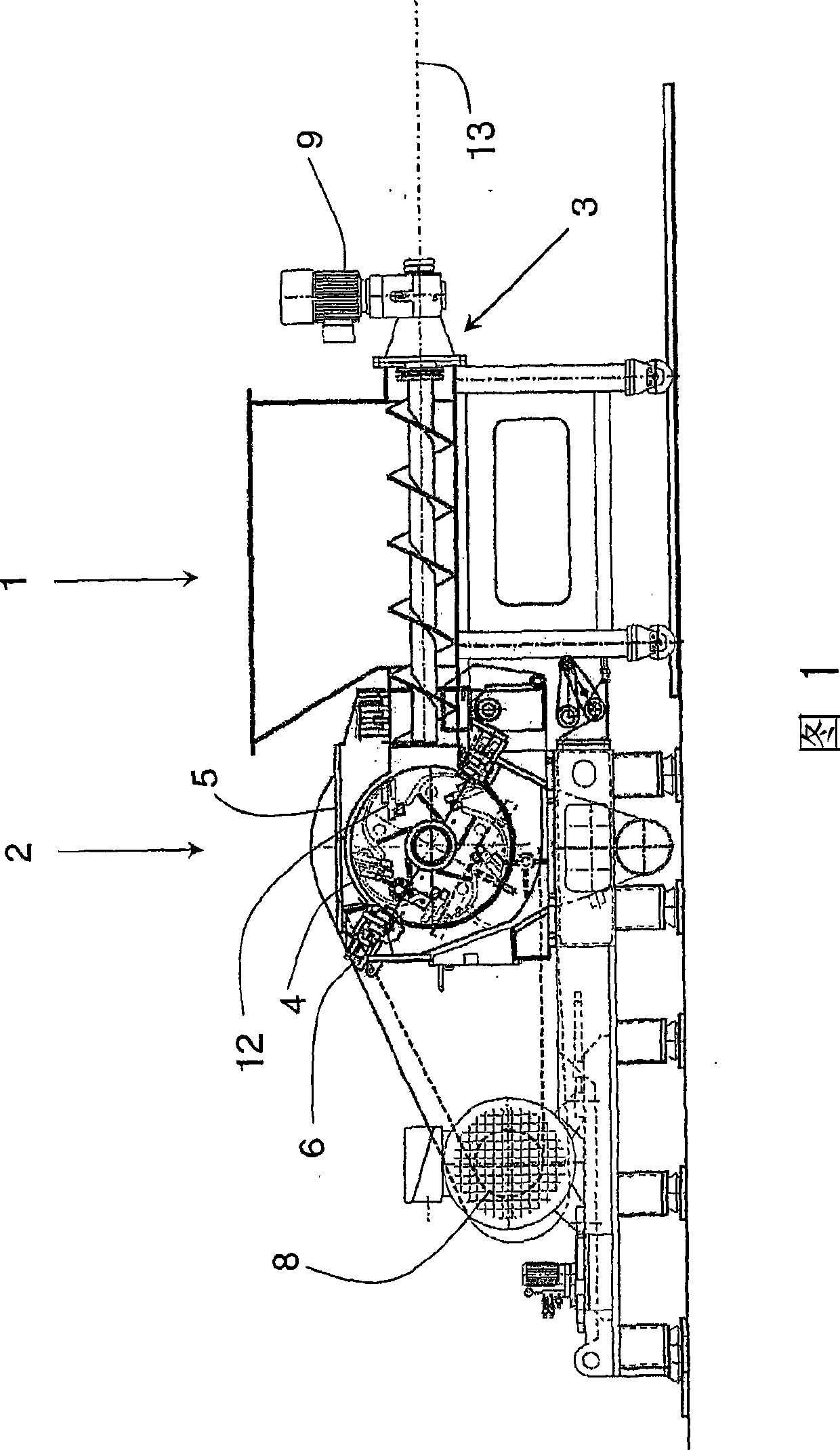

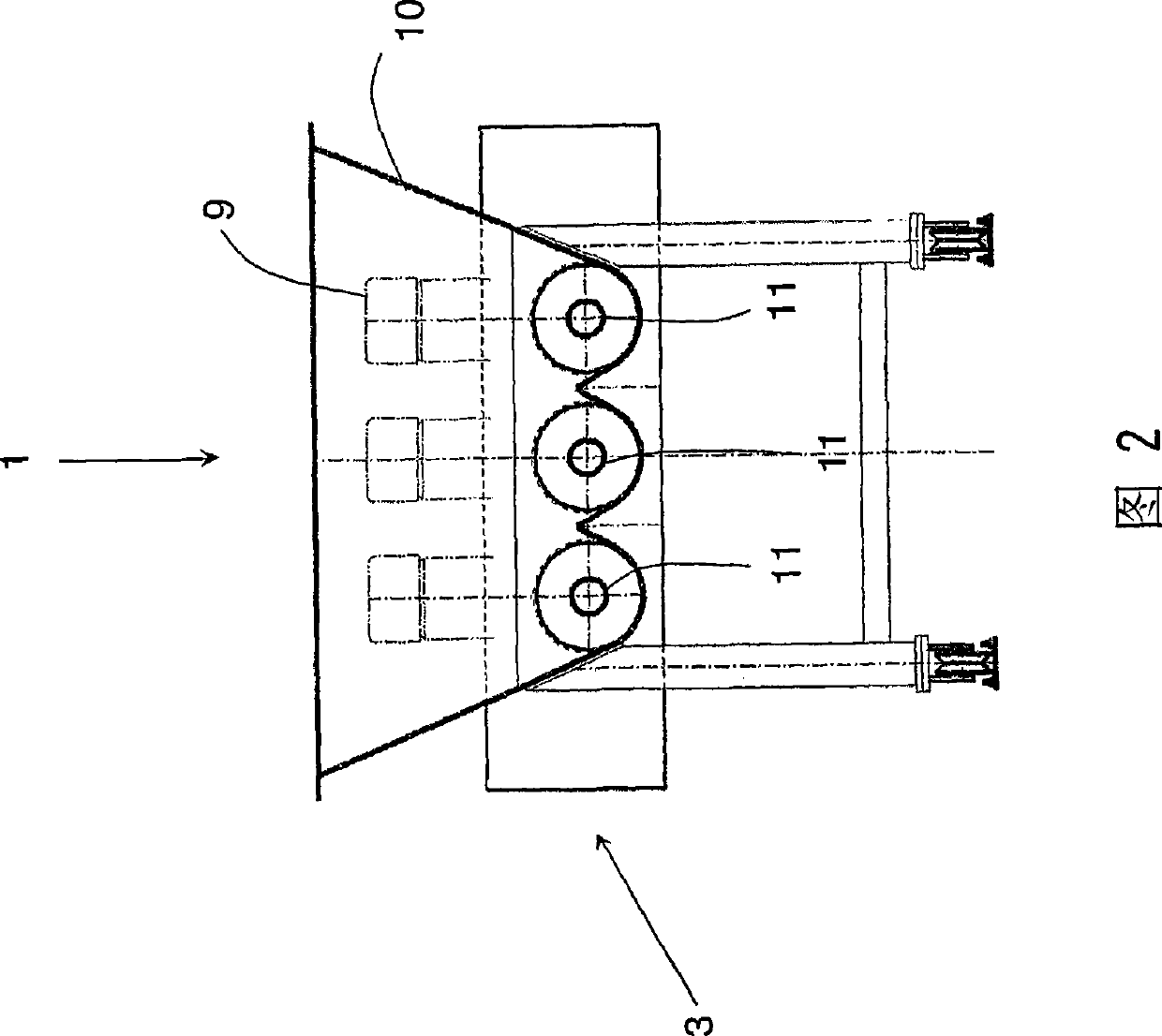

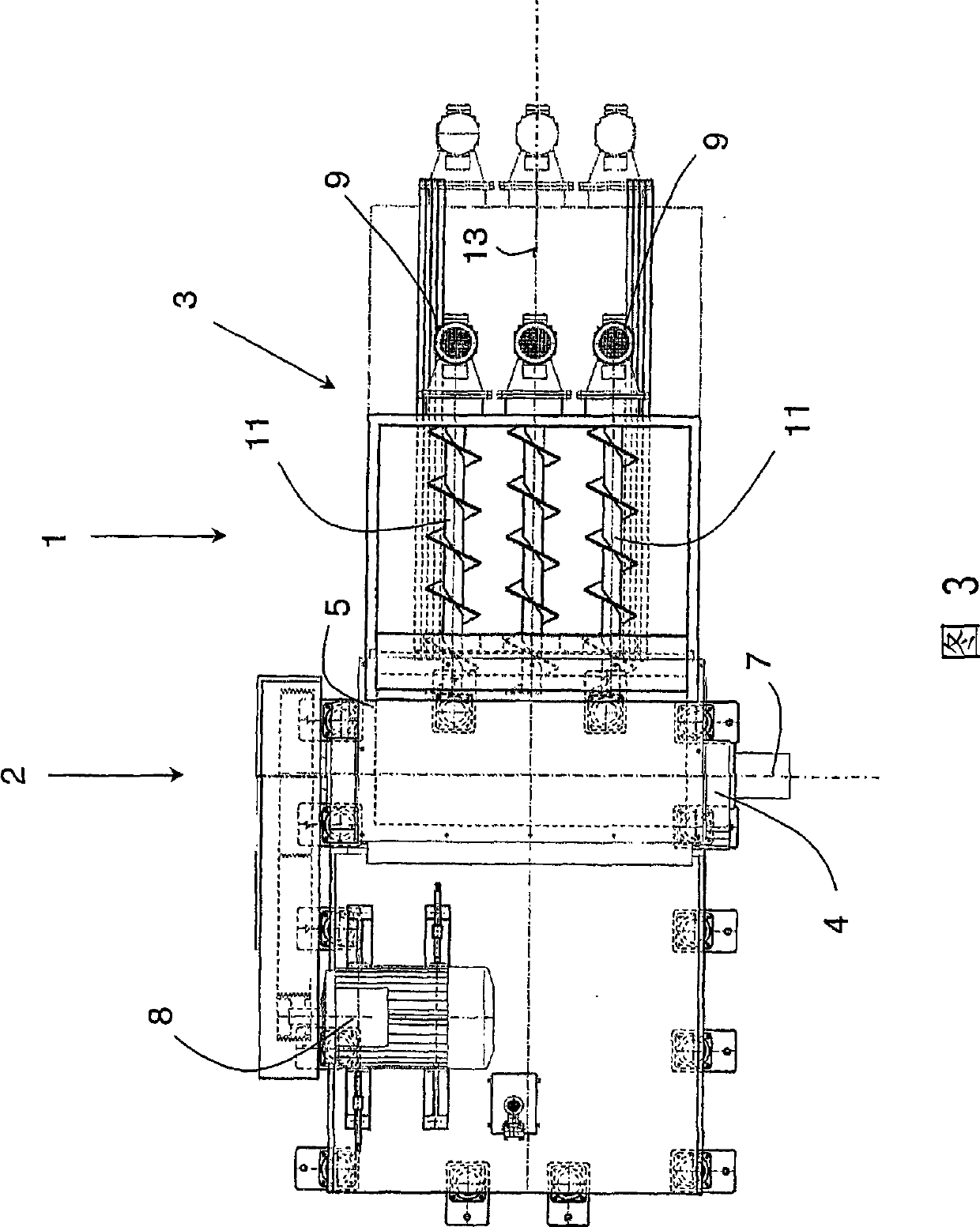

[0024] Figures 1 to 3 show an embodiment of a comminuting device for various types of components according to the present invention, wherein, in particular, the device is for comminuting plastic hollow bodies (not shown). Plastic bottles, such as PET bottles, are often shredded using such a device. The device comprises a feeding device 1 and a crushing device 2 . In the illustrated embodiment, the feeding device 1 comprises three conveying units 3 in total. The comminuting device 2 comprises a rotor 4 which is equipped with tools and rotates in a housing 5 . The housing 5 (sometimes also referred to as the stator) also houses the tool 6 .

[0025] 1 to 3 show that the delivery unit 3 is conveyed orthogonally to the axis of rotation 7 , which can be arranged at an angle in the range of 45° to 90° to the axis of rotation 7 in a manner according to the invention.

[0026] Furthermore, the drive 8 of the rotor and the drive 9 of the conveying unit 3 are shown in the figure. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com