Shaped part and dual-color molding method for producing the shaped part

A technology of two-color forming and forming parts, applied in thin material processing, transportation and packaging, etc., can solve the problems of high temperature resistance and temperature difference, limited product material selection, products cannot be made by two-color forming method, etc., to avoid punching, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The two-color molding method of the present invention and the molded parts made by the two-color molding method can be applied to various types of product devices, such as portable electronic devices such as mobile phones, game machines, and personal digital assistants (PDA). device.

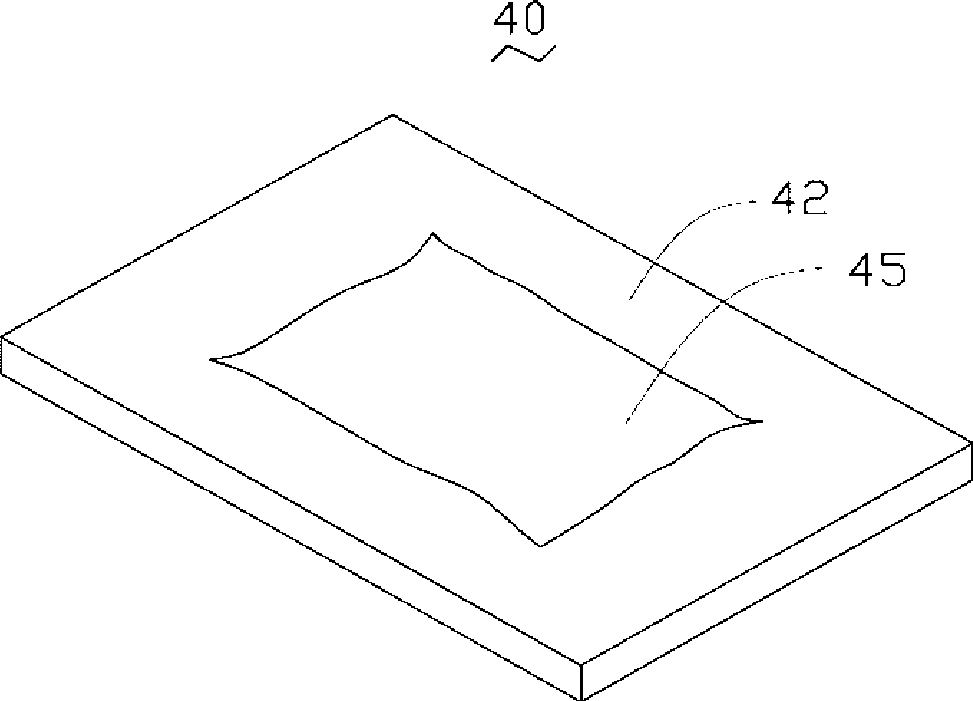

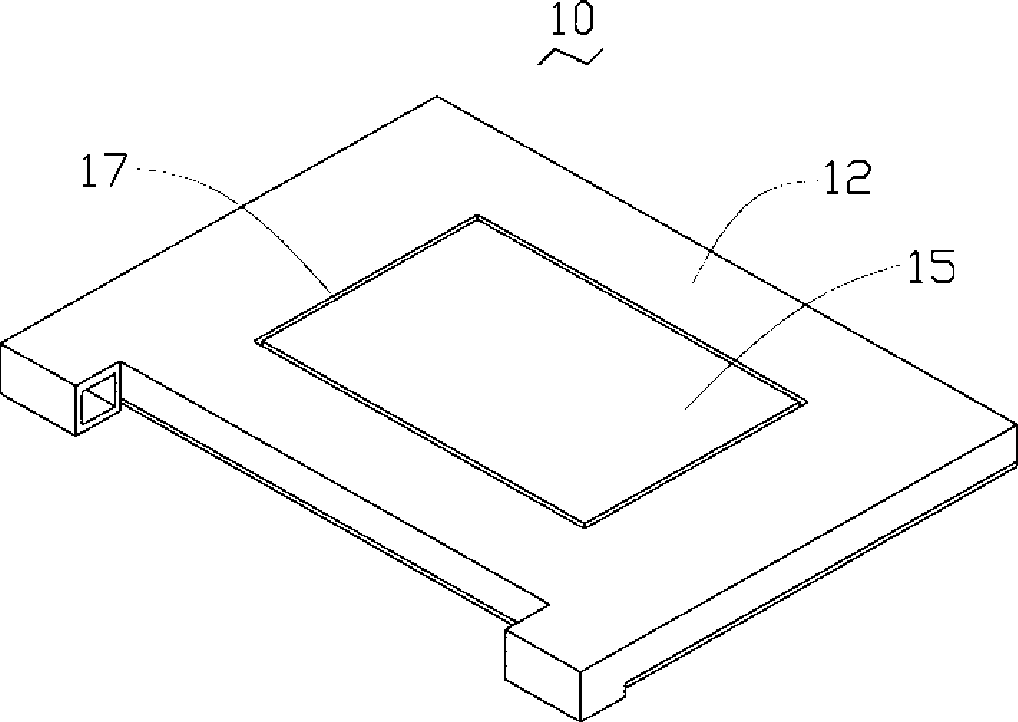

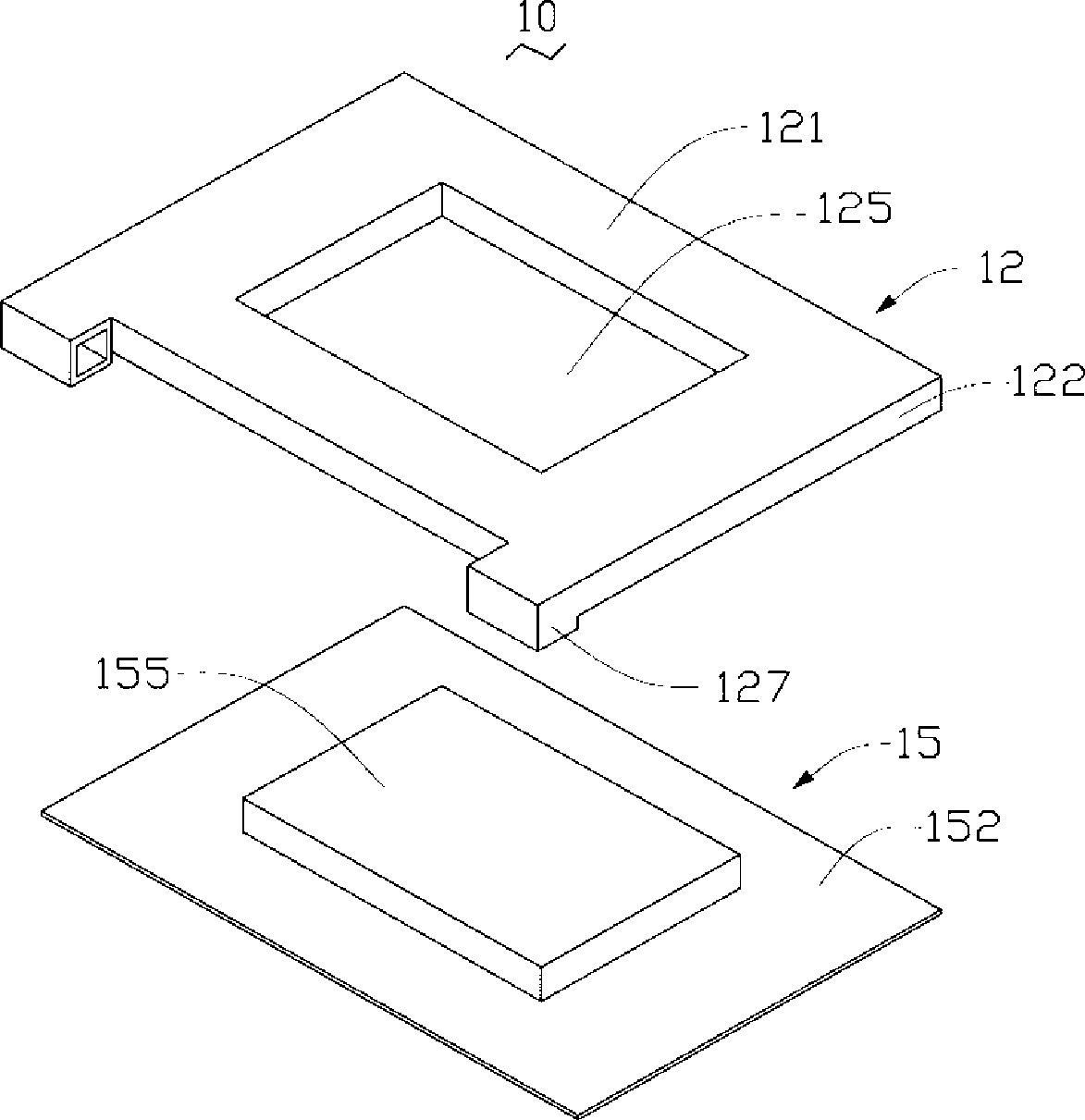

[0028] see figure 2 and Figure 4 As shown, the molded part 10 includes a first injection part 12 and a second injection part 15, and the first injection part 12 and the second injection part 15 are embedded in one body through the injection molding method.

[0029] Please also refer to image 3 and Figure 5 , the first shooting part 12 includes a main body 122 , a through slot 125 and a mounting portion 127 . The main body 122 is a substantially rectangular flat plate, which includes an upper surface 121 and a lower surface 123 opposite to the upper surface 121 . The through groove 125 is substantially rectangular, and is formed by opening substantially from the center of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com