Electronic device and power converting unit thereof

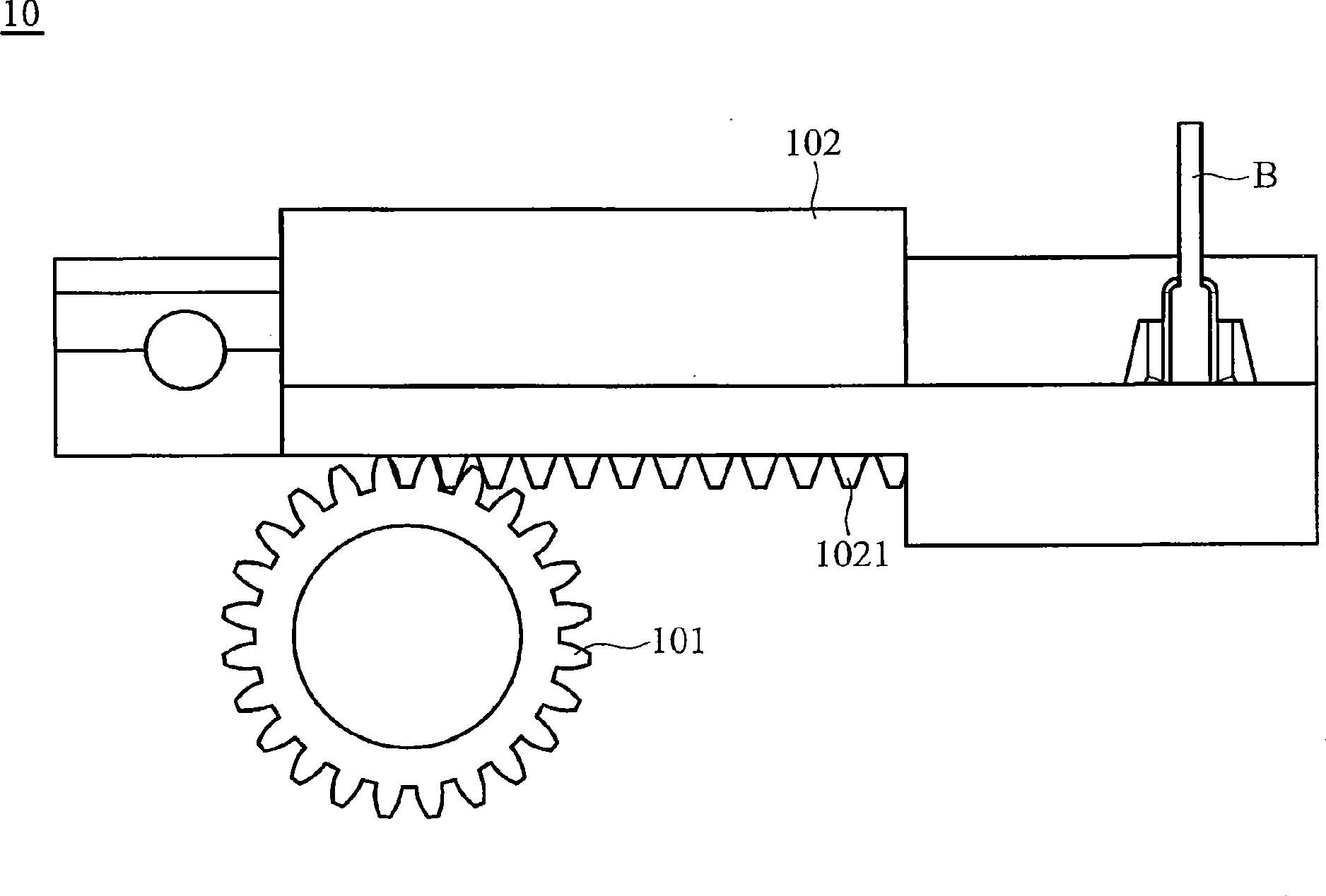

A technology of electronic devices and drive shafts, applied in printing and other directions, can solve the problems of gear and rack surface impact, tooth surface damage, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

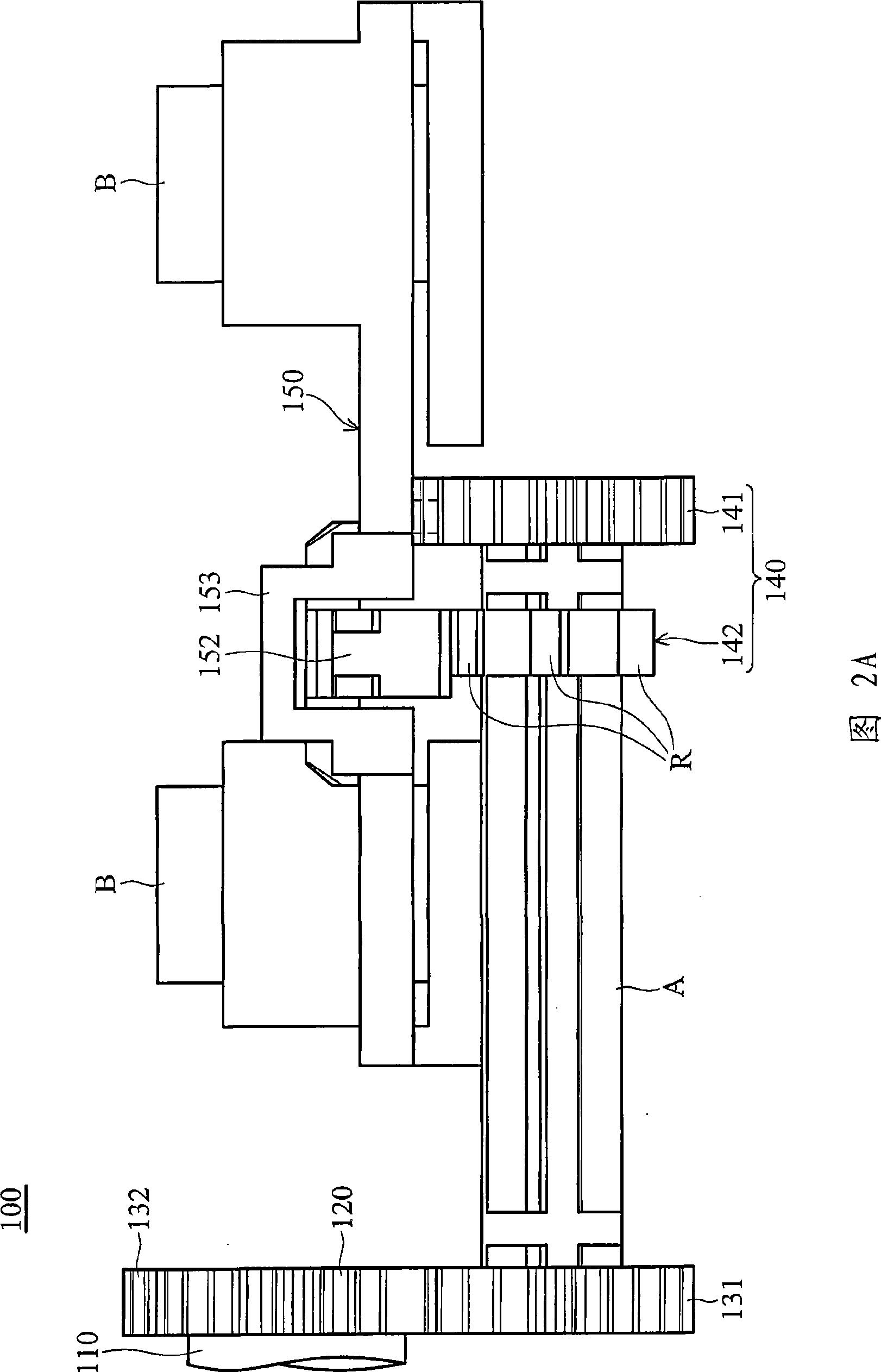

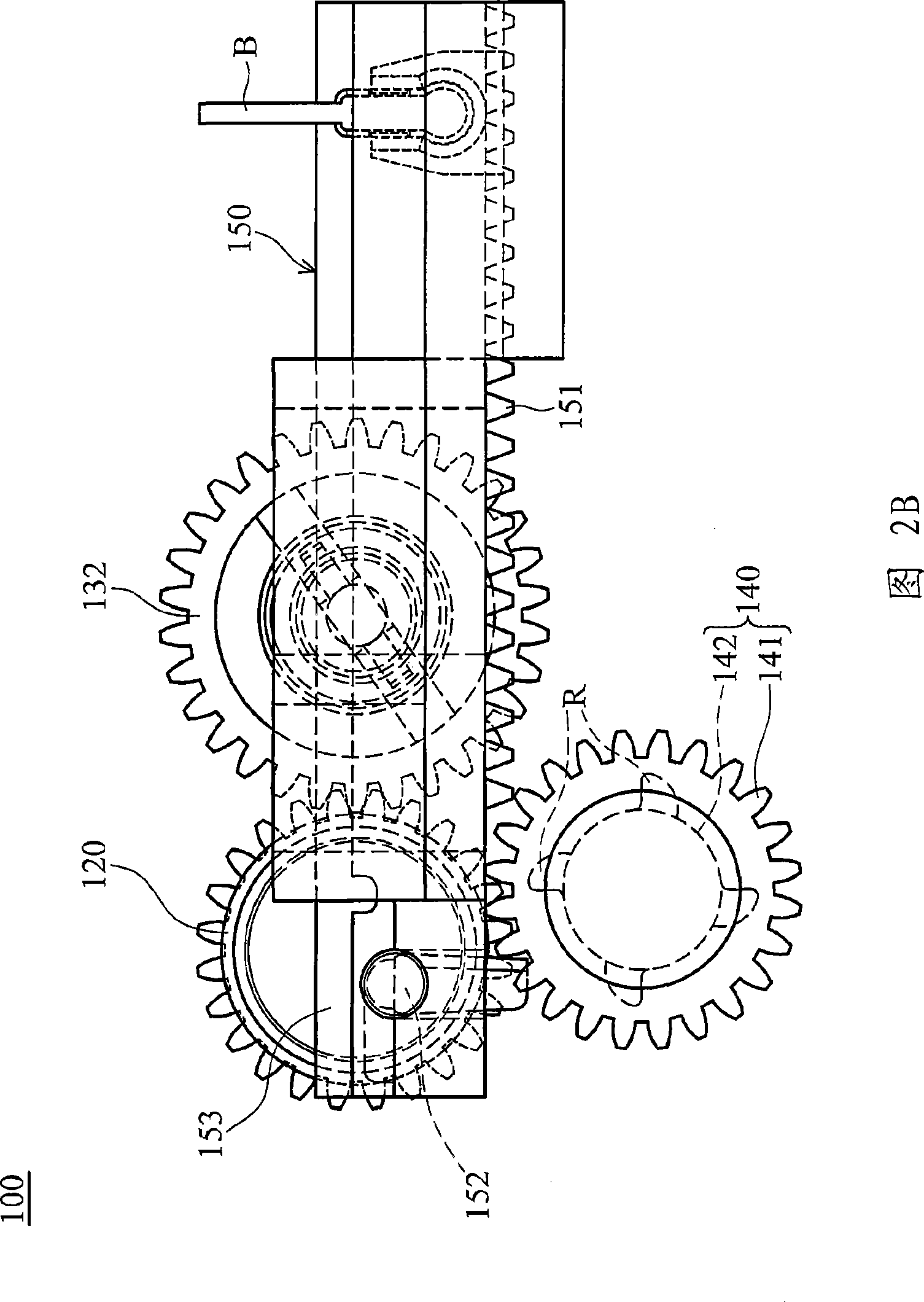

[0036] Referring to Fig. 2A and Fig. 2B, the electronic device 100 of the present invention is a printer, a fax machine, a photocopier or a multifunctional business machine, including a paper feeding mechanism, a cleaning inkjet head mechanism, a power conversion unit and a power device .

[0037] The power conversion unit includes a transmission shaft 110, a driving wheel 120, a first driven wheel 131 and a second driven wheel 132, the transmission shaft 110 is electrically connected with a power device to provide the power for the transmission shaft 110 to rotate, the transmission shaft 110 Connected with the driving wheel 120 to drive the driving wheel to rotate, the first driven wheel 131 and the second driven wheel 132 mesh with the driving wheel respectively. If the position of the wheel train is changed, the first driven wheel 131 can be selectively switched to be connected with the cleaning inkjet head mechanism (as shown in FIG. The driving wheel 132 can be selective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com