Distributor capping apparatus for bottles

A dispenser and sealing device technology, applied in the field of dispenser capping devices, can solve problems such as incomplete solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

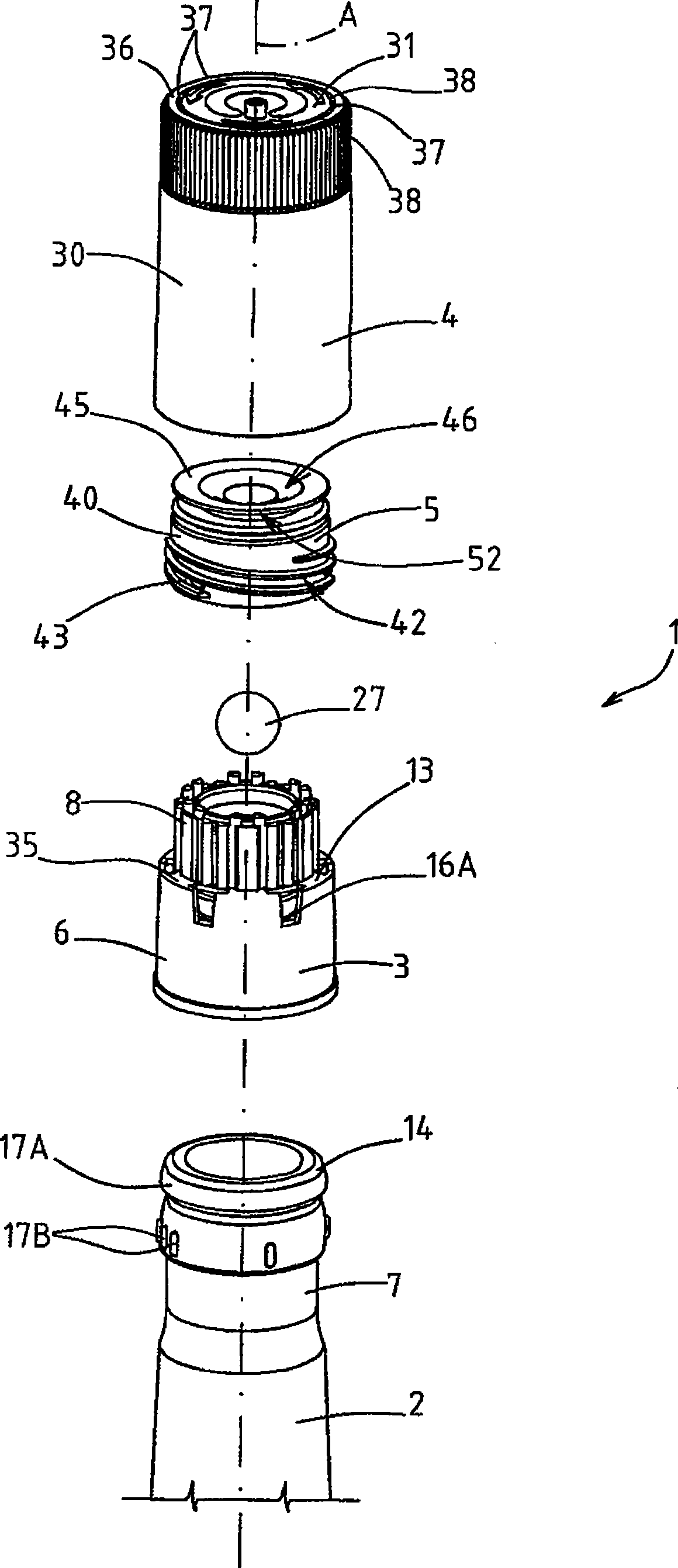

[0015] figure 1 In, "1" refers to a dispenser capping device for a bottle 2, which may be, for example, a wine bottle or other alcoholic beverage bottle.

[0016] The device 1 is formed substantially along the axis A and consists of a base 3, a handle element 4 and a nozzle 5, preferably all in one piece of plastic material.

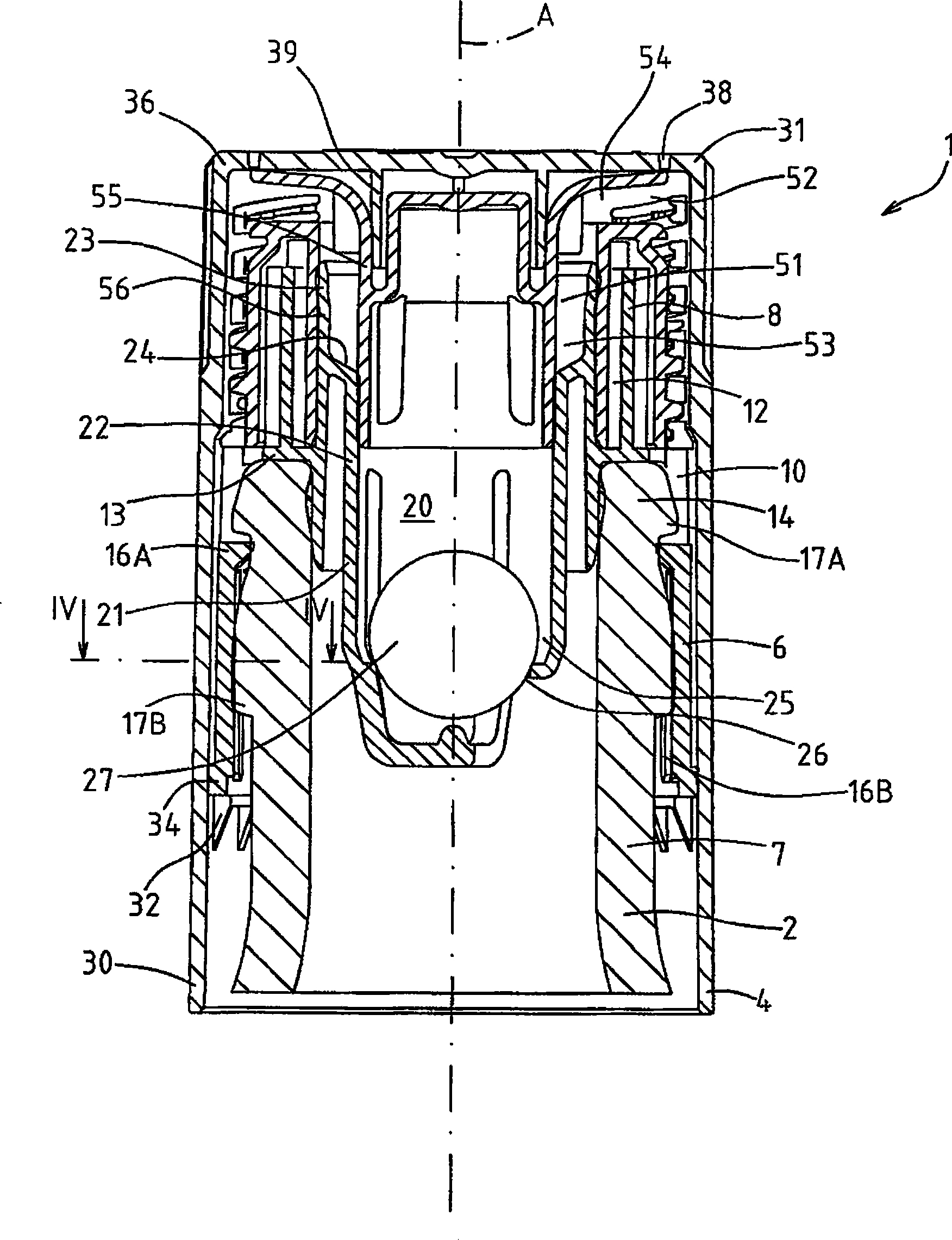

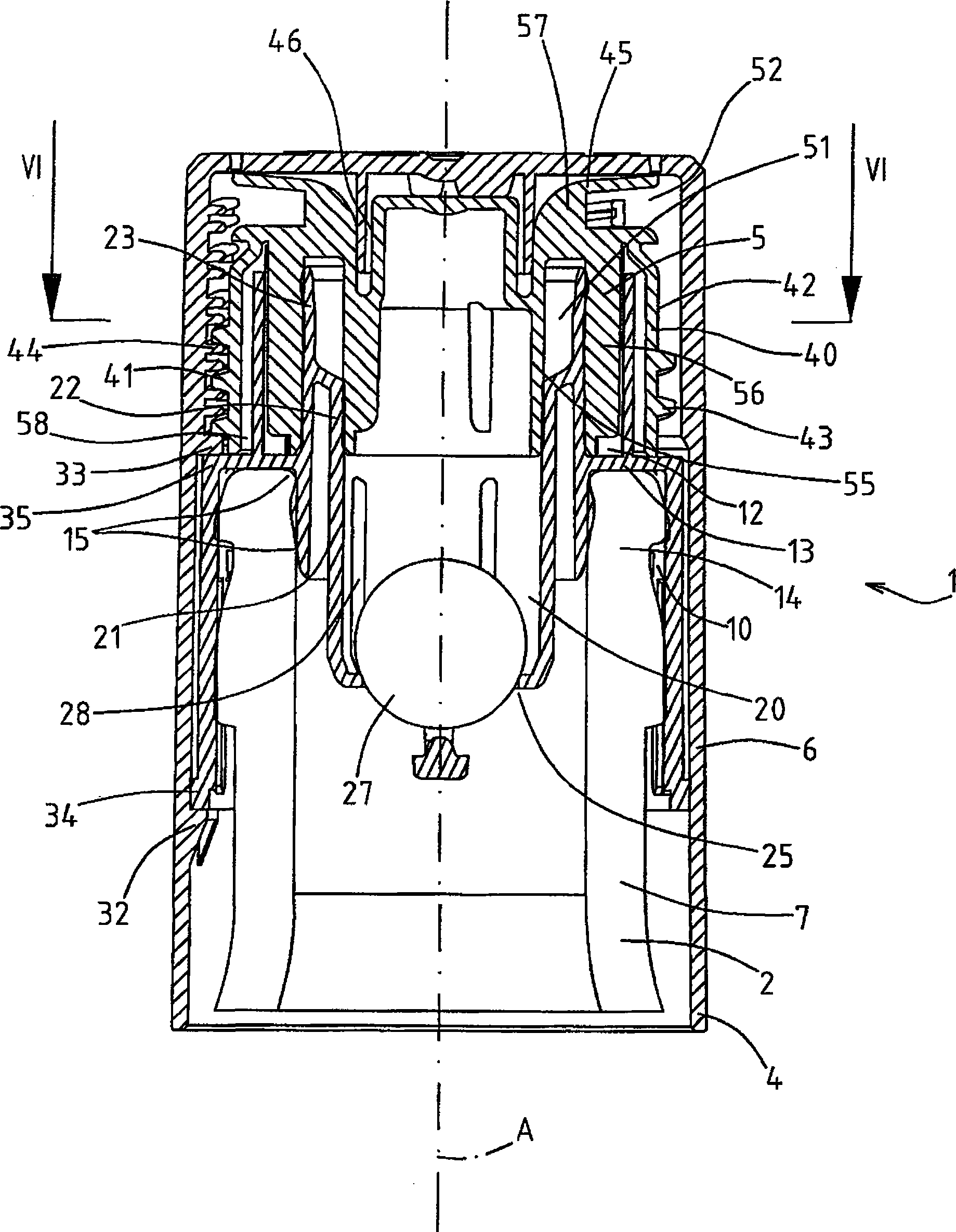

[0017] see figure 2 -4, the base 3 is composed of a coupling part 6 and a guide part 8, the coupling part 6 is used to fasten on the neck 7 of the bottle 2, and the guide part 8 protrudes axially from the part 6 to cooperate with the nozzle 5; part 6, 8 is provided with respective recesses 10 , 12 substantially surrounding the axis A and facing axially, the recesses 10 , 12 being bounded by respective pairs of substantially cylindrical and coaxial side walls, connected by an annular flange 13 .

[0018] The recess 10 is a coupling recess where the edge 14 of the neck 7 is inserted and provided with sealing means 15 for fluid-tight connection between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com