Centrifugal fan

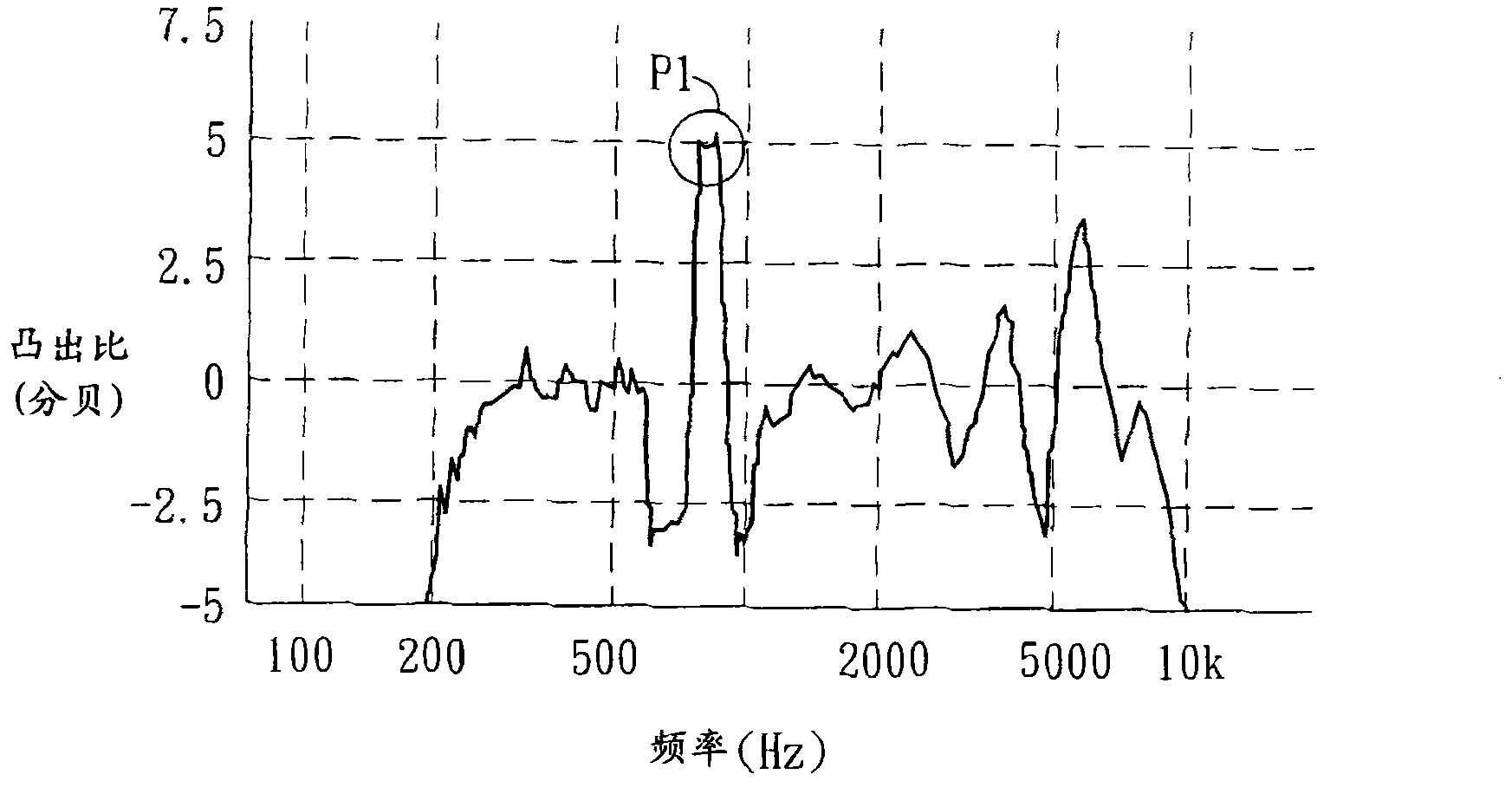

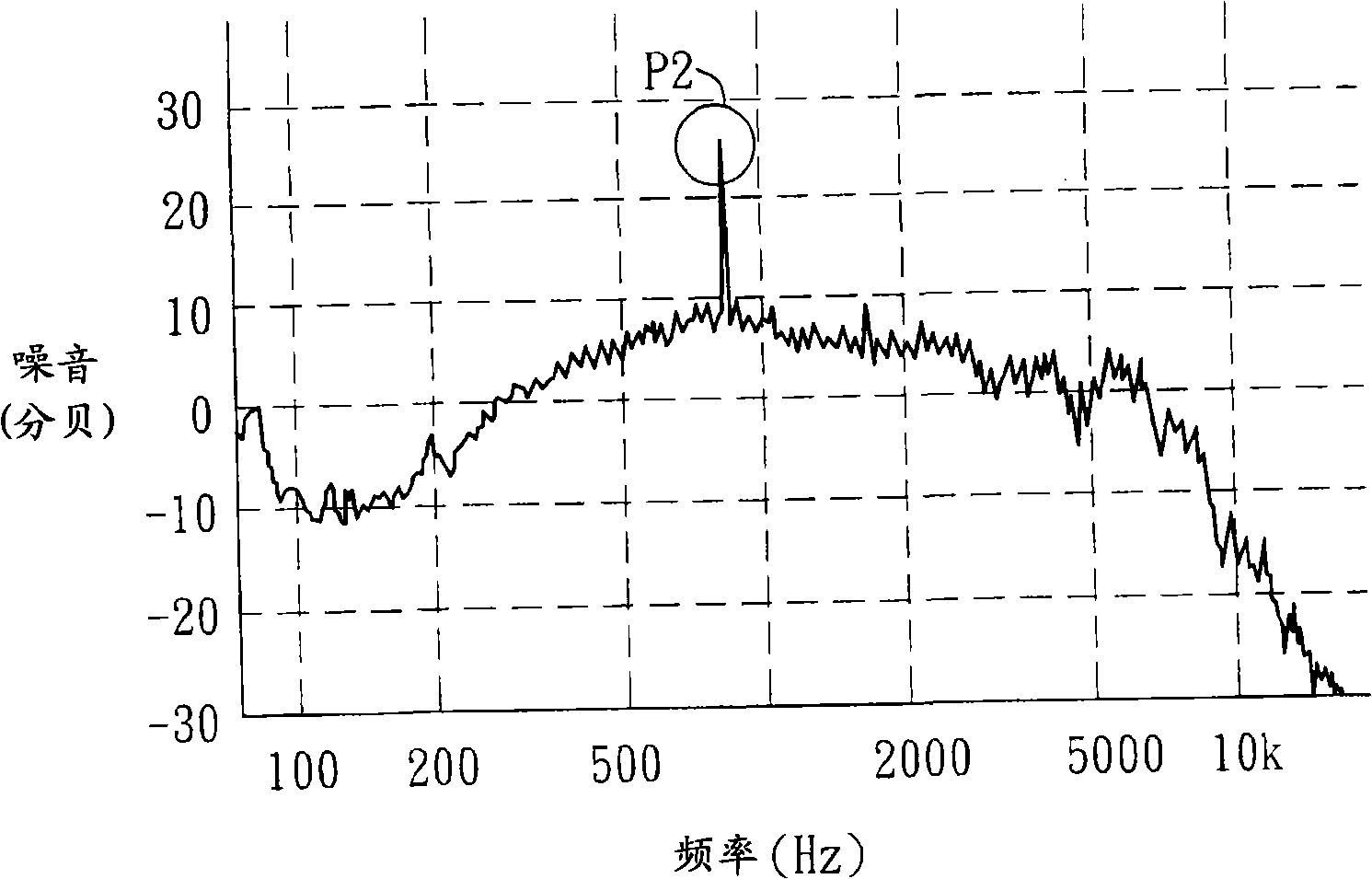

A centrifugal fan and fan blade technology, used in non-variable volume pumps, non-displacement pumps, components of pumping devices for elastic fluids, etc., can solve problems such as high fan blade frequency peaks and reduce convexity Output ratio peak, improve gradient change, avoid the effect of fan blade frequency peak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the centrifugal fan according to the present invention will be described with reference to related drawings.

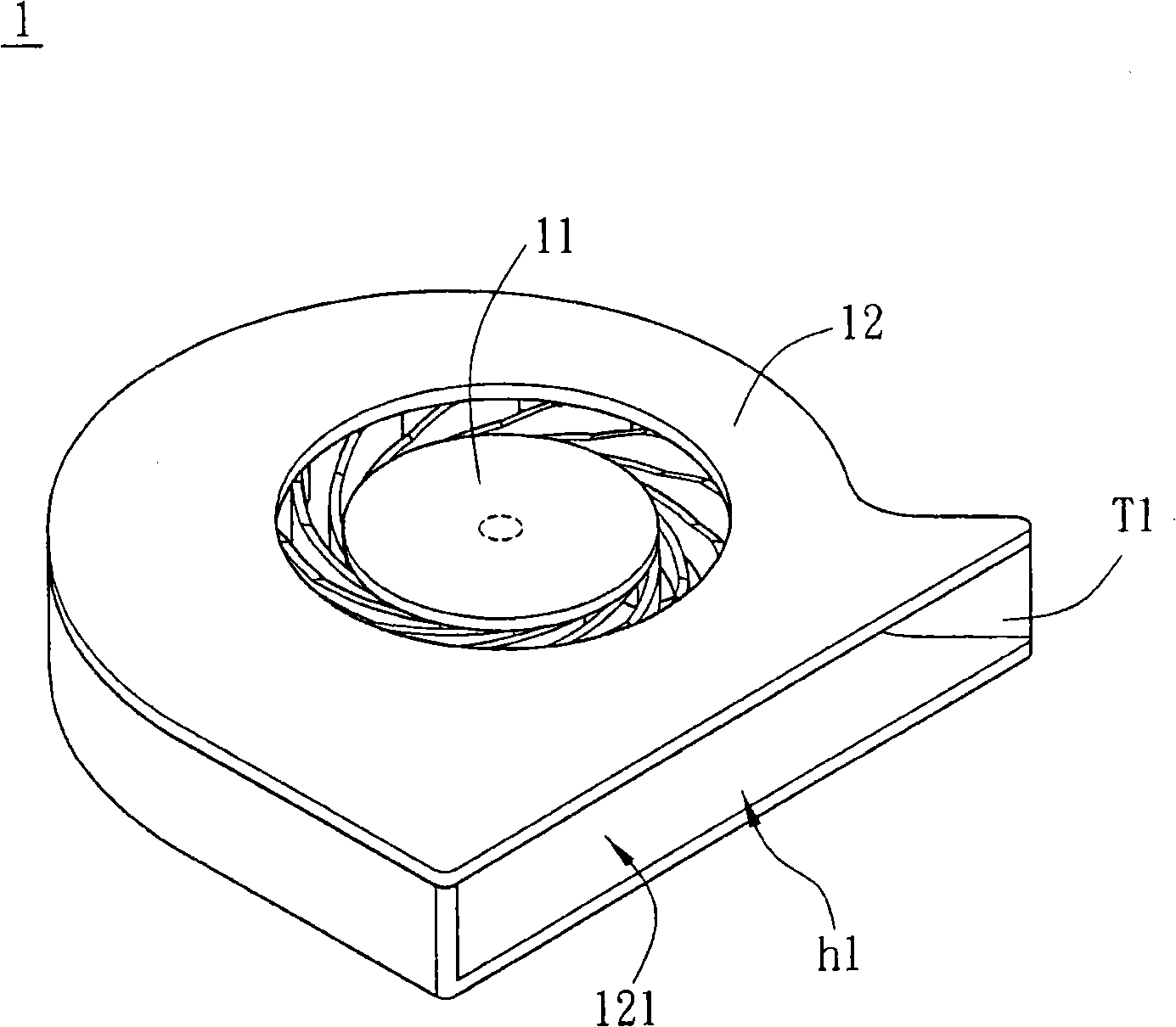

[0039] Please refer to Figure 3A As shown, the centrifugal fan 2 according to the first embodiment of the present invention includes a blade body 21 and a casing 22 .

[0040] The blade body 21 has an axis 211 . The casing 22 has an accommodating portion 221 , an axis fixed point 222 , a throat T2 and a recess 23 . In addition, the housing 22 further has a first sub-housing 223 , a second sub-housing 224 and an air outlet H1 . The first sub-housing 223 has a wall 223a, a bottom 223b and an air inlet H2, the wall 223a is disposed along the bottom 223b, and the second sub-housing 224 has an air inlet H3.

[0041] The blade body 21 is disposed in the accommodating portion 221 with the axis 211 corresponding to the axis fixed point 222 . Also, please refer to Figure 3B As shown, it is a top view of the first housing 223, if the first sub-housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com