Hollow stem water-mixed wellhead device

A technology of wellhead device and hollow rod, which is used in wellbore/well components, production fluids, earth-moving drilling, etc. The effect of long life, high pressure resistance and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

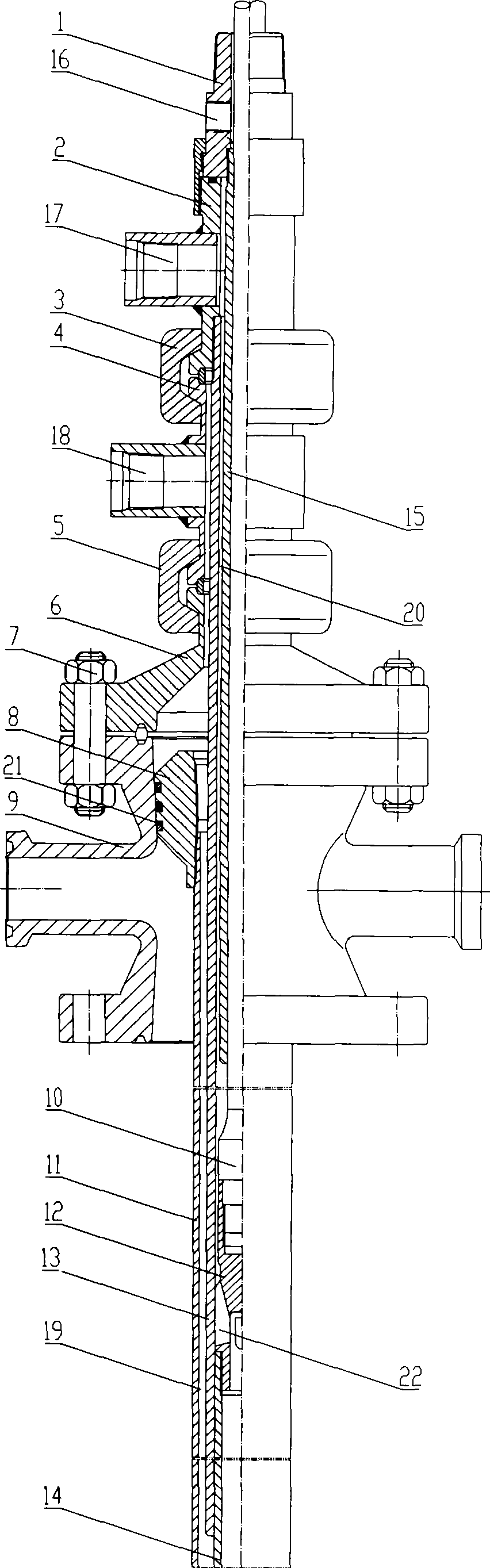

[0008] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0009] The embodiment of the present invention consists of a pressure relief joint 1, a water-mixed tee 2, an upper clamp 3, an oil outlet tee 4, a lower clamp 5, a flange cover 6, bolts 7, a suspension sealing joint 8, and a wellhead cross 9 , polished rod 10, oil extraction pipe 11, Unicom joint 12, pressure isolation pump barrel 13, pressure isolation plunger 14, and sealing tube 15. Thread and connection water-mixed tee 2, water-mixed tee 2 and oil outlet tee 4 are connected by upper clamp 3, oil outlet tee 4 and flange cover 6 are connected by lower clamp 5, flange cover 6 and wellhead The cross 9 is connected by bolt 7, the upper thread of the pressure isolation pump barrel 13 is connected with the internal thread of the water-mixed tee 2, the suspension sealing joint 8 is suspended in the wellhead cross 9, the lower part of the suspension sealing joint 8 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap