Label printing machine

A trademark printing machine, printing mechanism technology, applied in printing machines, rotary printing machines, printing, etc., can solve the problems of uneven force, inaccurate overprinting, low quality, etc., and achieve the effect of solid, accurate and perfect writing, printing down-to-earth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

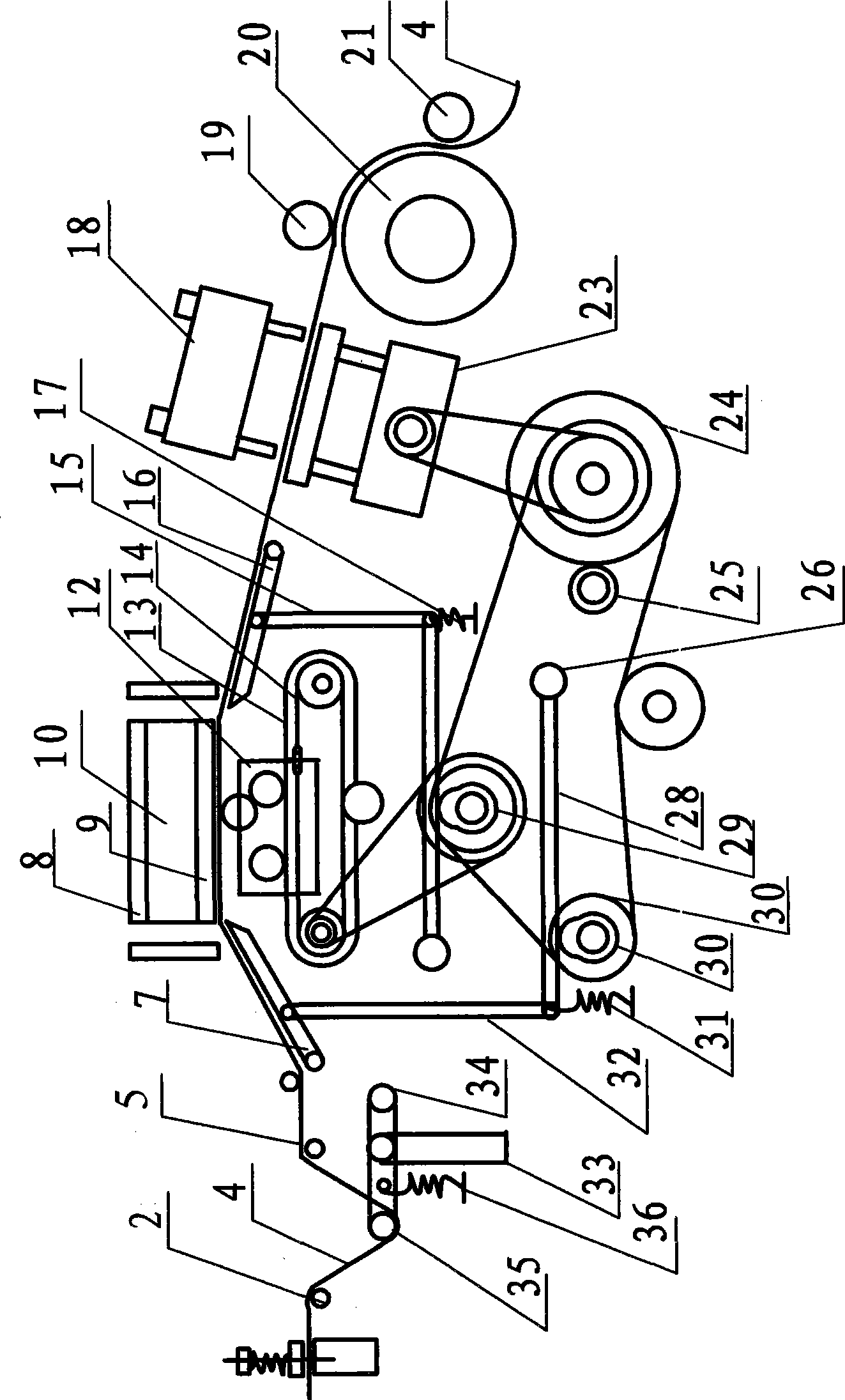

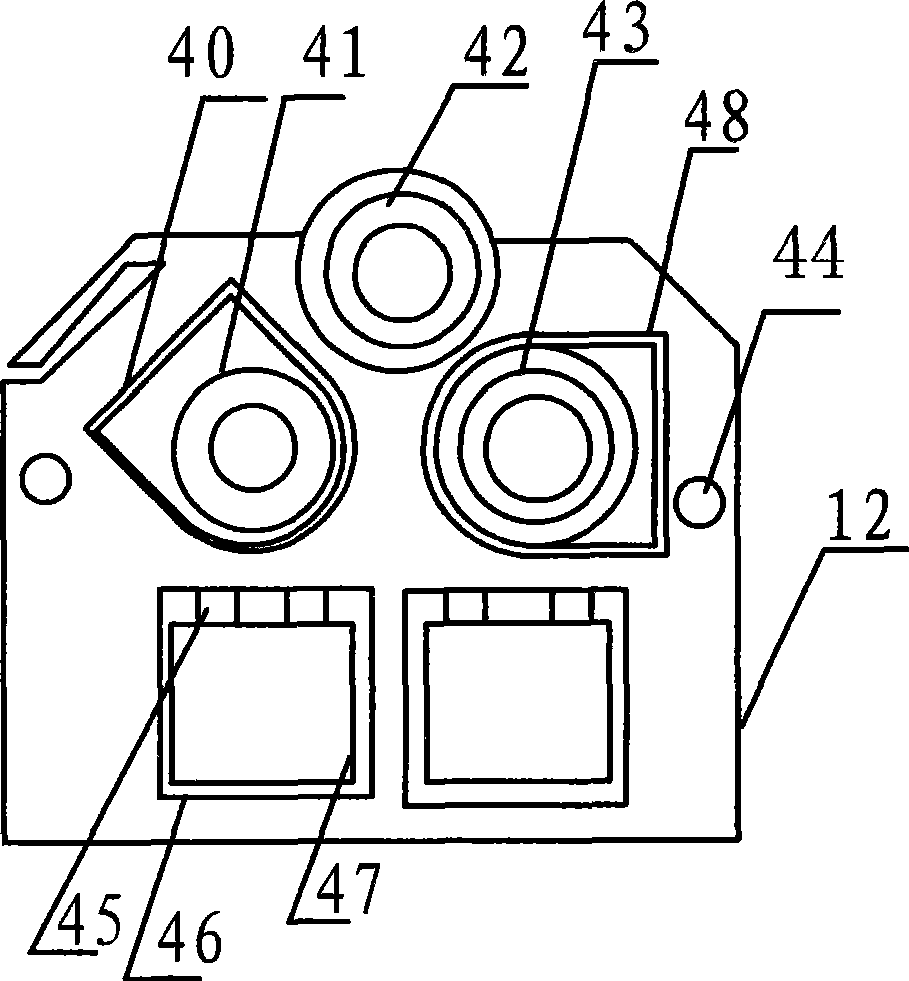

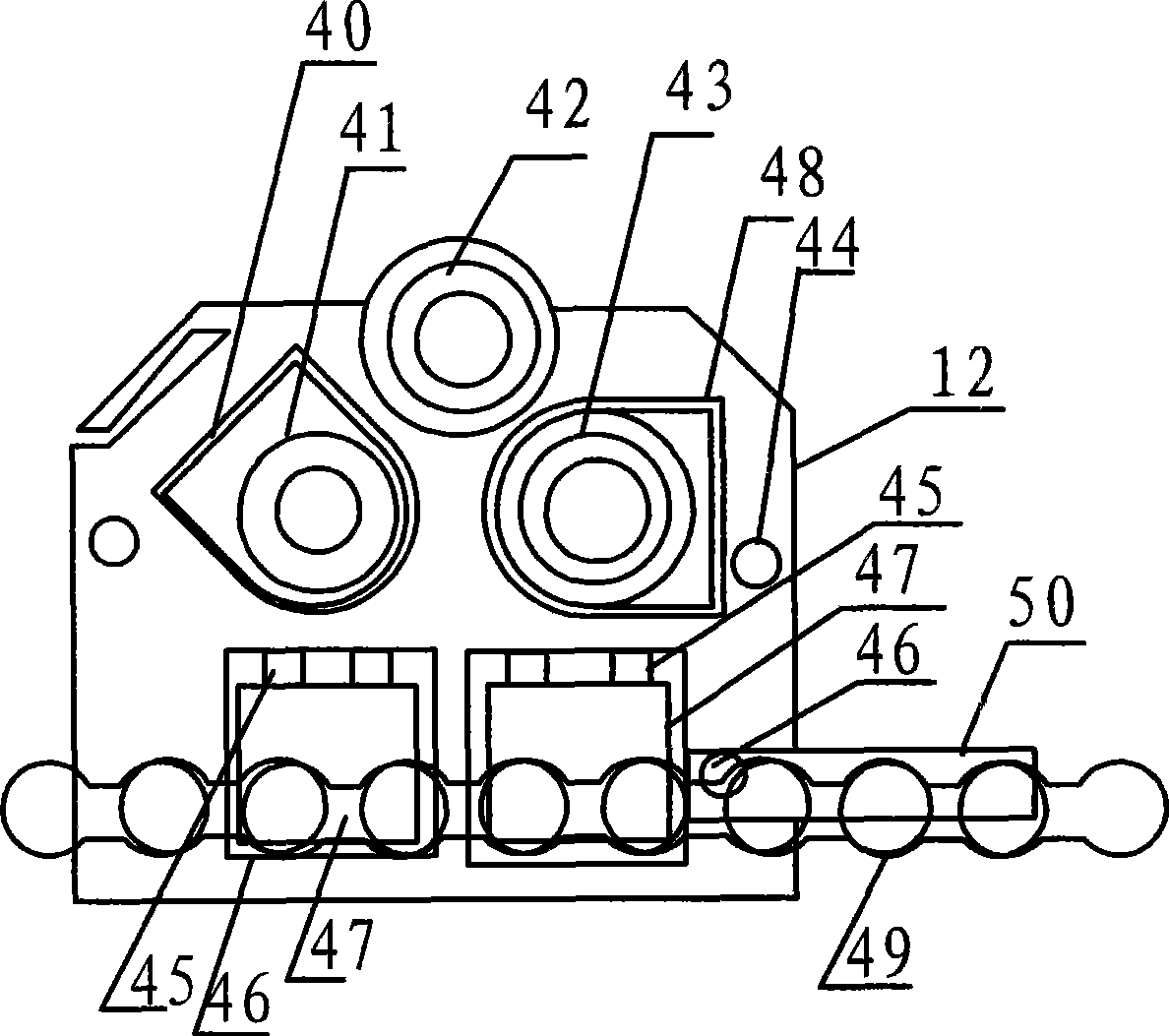

[0031] refer to figure 1 , 2 , 3, shown in 4, the specific embodiment of the present invention is as follows:

[0032] A trademark printing machine, including a frame, a paper feeding mechanism, a paper pressing mechanism 34, a top paper transmission mechanism, an inking printing mechanism 8, a molding mechanism 18, a paper pulling mechanism, a driving transmission mechanism, and a rotary printing roller shaft mechanism , Jacking paper transmission mechanism; an inking printing mechanism is set directly above the rotary printing roller shaft mechanism, and the inking printing mechanism is used to ink the printing plate, and a top paper transmission mechanism is set directly below the inking printing mechanism. The mechanism is used with the rotary printing roller mechanism, the front of the rotary printing roller mechanism is provided with a described paper pressing mechanism, the front of the rotary printing roller mechanism is provided with a said molding mechanism 18, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap