Casting method of heat-resistant steel slime blind-tube and mold thereof

A technology of heat-resistant steel and blind pipe, applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of easy deformation of the mold core, eccentric sand core, complex process, etc., and achieve a simple casting method and not easy to damage The effect of deformation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

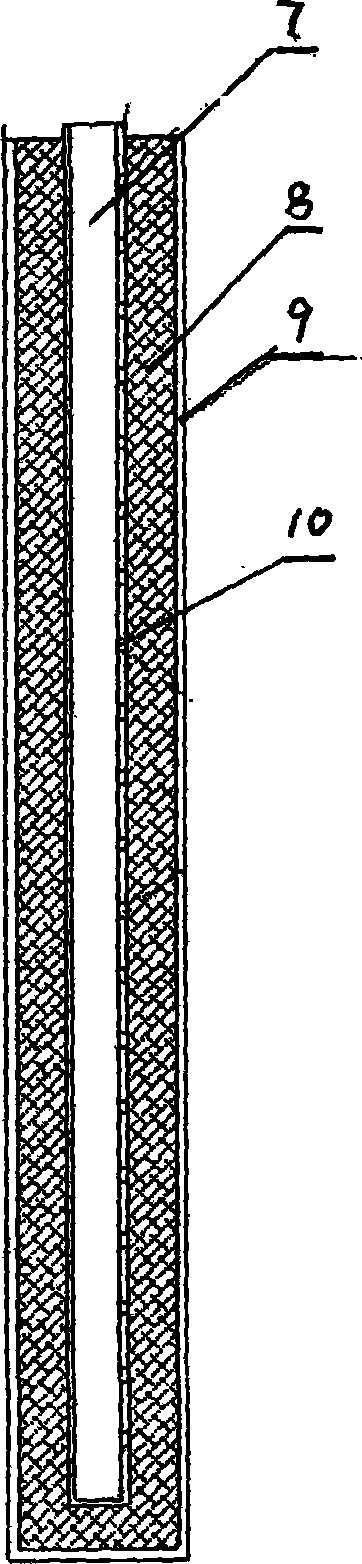

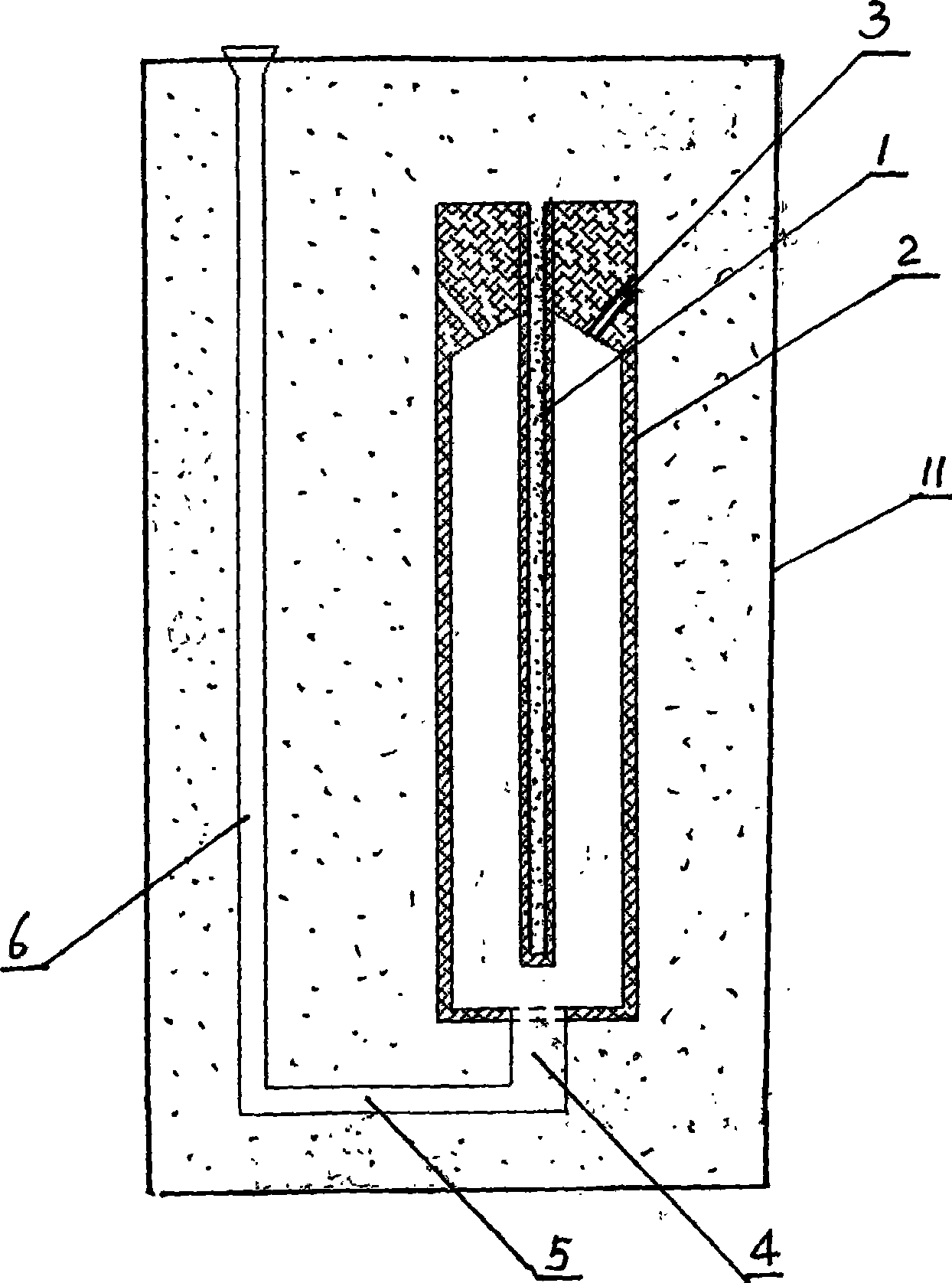

[0030] Refer below figure 1 and figure 2 The casting method and model structure of the present invention are further described.

[0031] 1. Make composite mandrel 1 according to the geometric dimensions of the slender blind tube. Cut a thin steel pipe 7, the diameter of the thin steel pipe 7 is 1.2-2.5 mm less than the diameter of the blind pipe to be made, and the length of the thin steel pipe 7 is equal to the sum of the blind hole length and the clamping length of the sand mold shell 2; drill on the thin steel pipe 7 wall There are small holes 10, and there are no strict requirements on hole diameter, hole distance, and arrangement. After drilling, resin sand 8 with a thickness of 1 to 2 mm is coated on the surface of thin steel pipe 7. The resin sand 8 used is covered with phenolic resin with high strength and low gas generation. Membrane sand and resin sand 8 outer layer are evenly coated with 0.2-0.5mm thick coating 9 commonly used for casting heat-resistant steel, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com