Dilution water ring addition device of head box

A technology of adding device and diluting water, applied in textile and paper making, paper machine, wet end of paper machine, etc., can solve the problem of uneven concentration of local slurry, achieve uniform quantitative distribution globally, uniform quantitative distribution, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings. It should be noted that the specific embodiments do not limit the protection scope of the present invention.

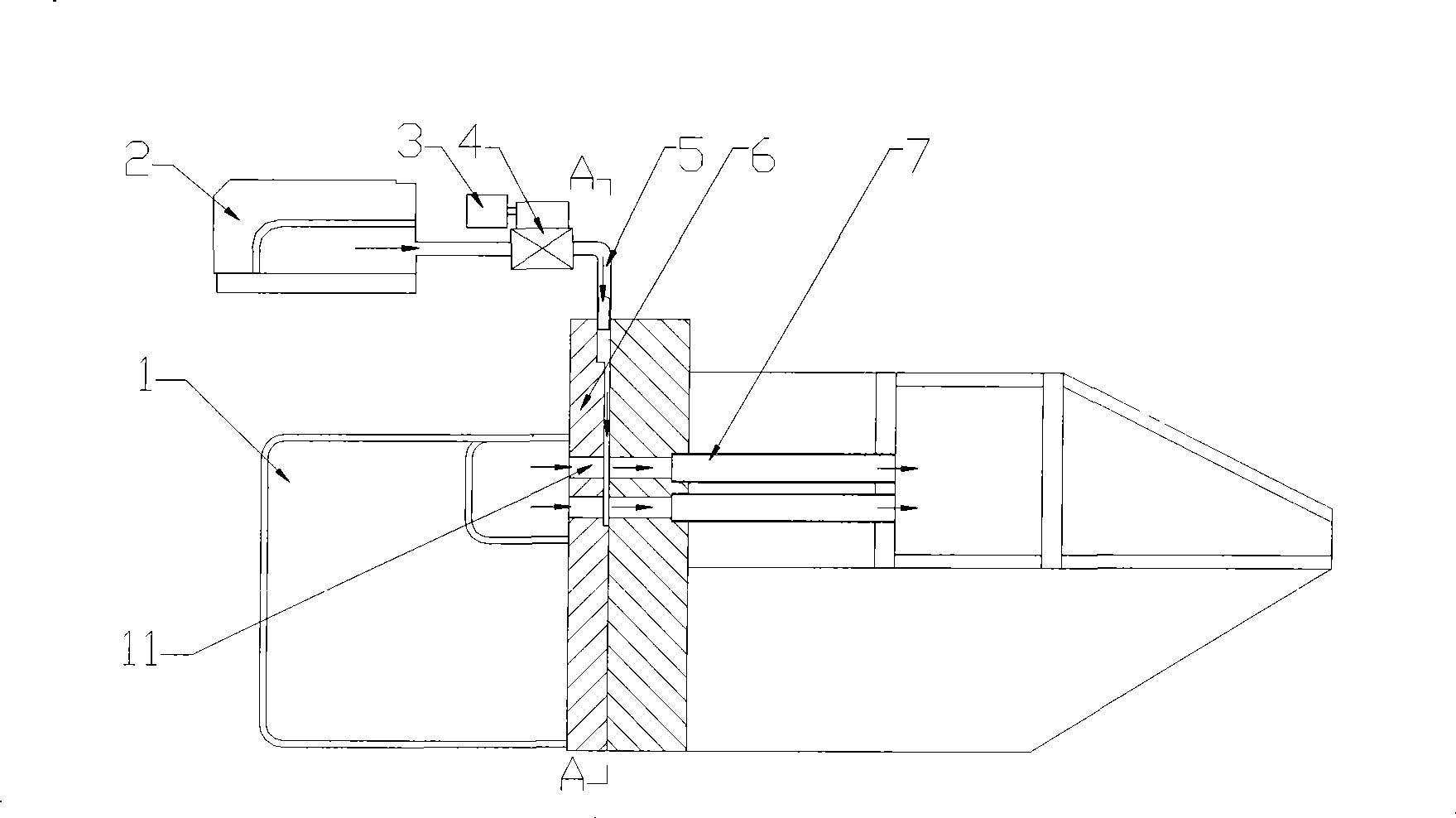

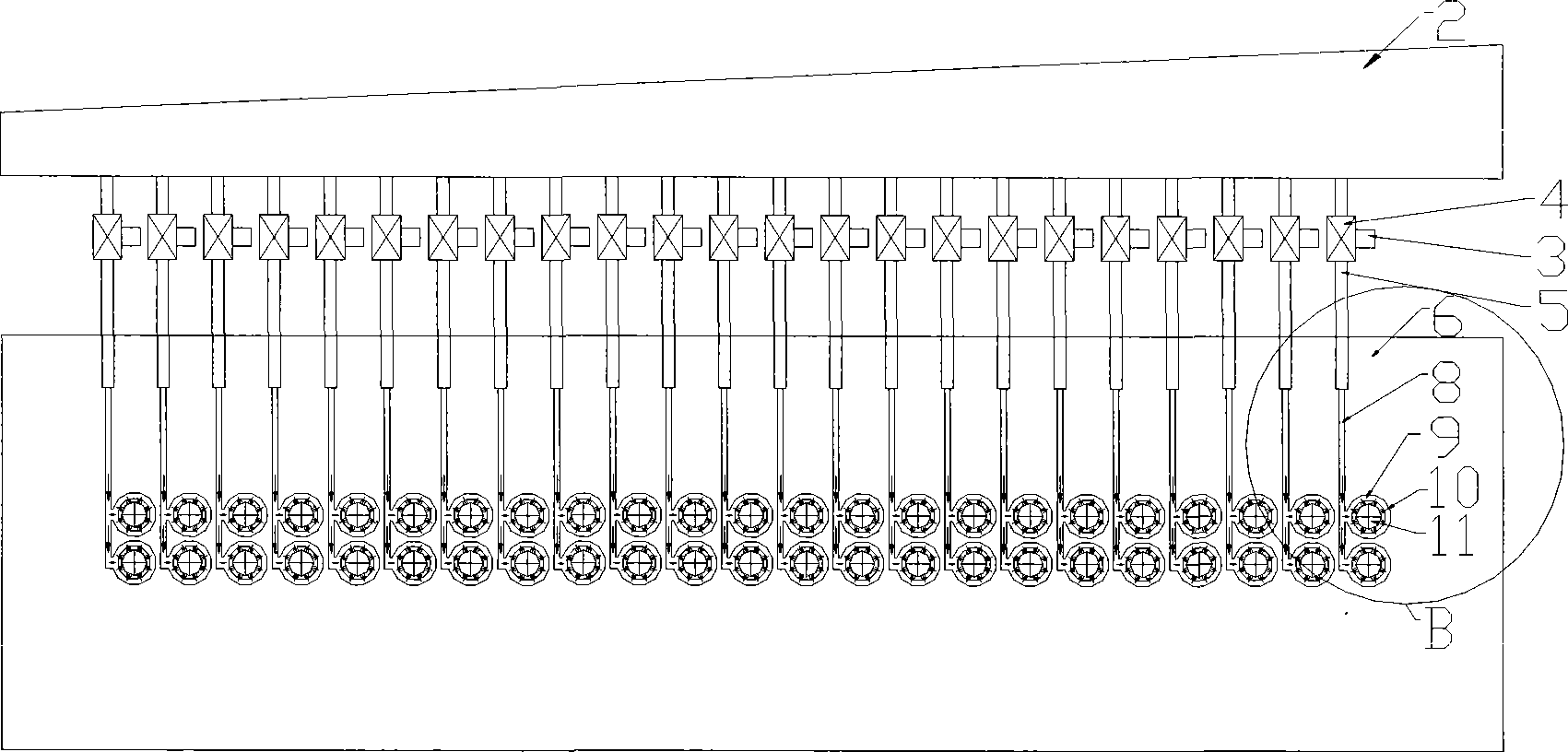

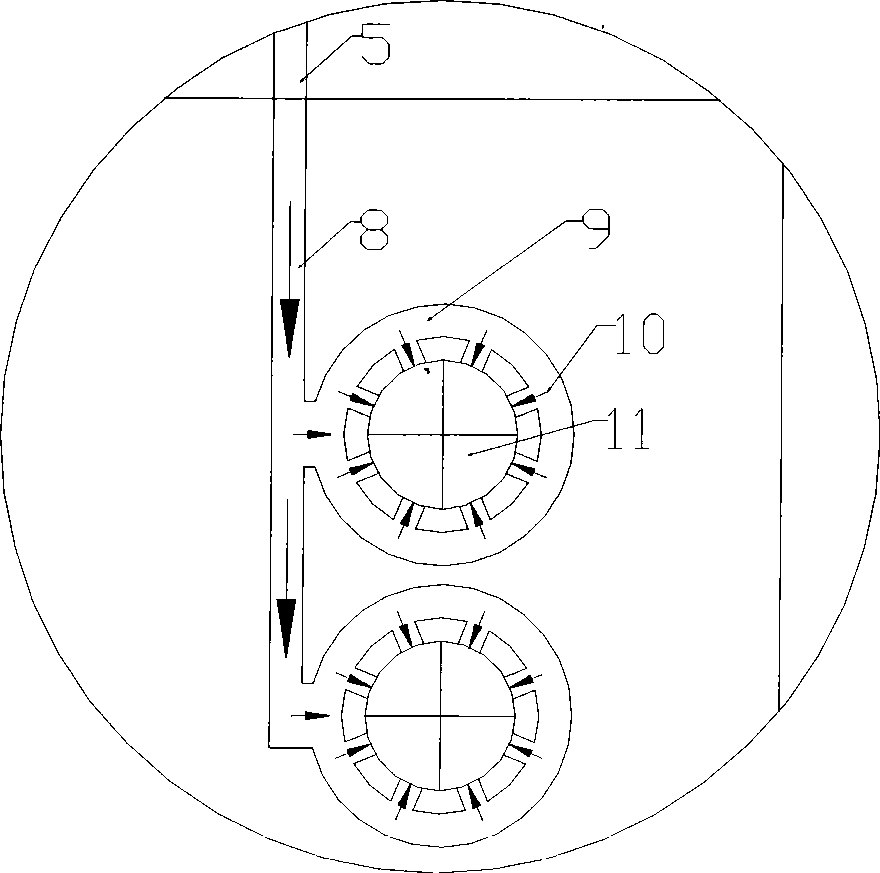

[0018] Such as figure 1 As shown, the dilution water ring adding device of the headbox is mainly composed of a dilution water main pipe 2, a stepping motor 3, a dilution water valve 4, a dilution water branch pipe 5, and a dilution water ring adding plate 6. The dilution water annular addition plate 6 is installed between the slurry inlet main pipe 1 and the tube bundle 7, the slurry in the slurry inlet main pipe 1 enters the tube bundle 7 through the slurry inlet hole 11 on the dilution water annular addition plate 6, and the dilution water is added through the dilution water ring at the same time The adding unit of the plate 6 is distributed to the corresponding slurry inlet hole 11, uniformly mixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com