Split technique for processing for SL01 type split-bearing

A processing technology and splitting technology, which is applied in the field of splitting processing technology of SL01 type split bearings, can solve the problems of few bearing enterprises and difficulty in mastering the splitting process and processing technology, and achieve strong processing technology and easy mastery And the effect of realizing and satisfying product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

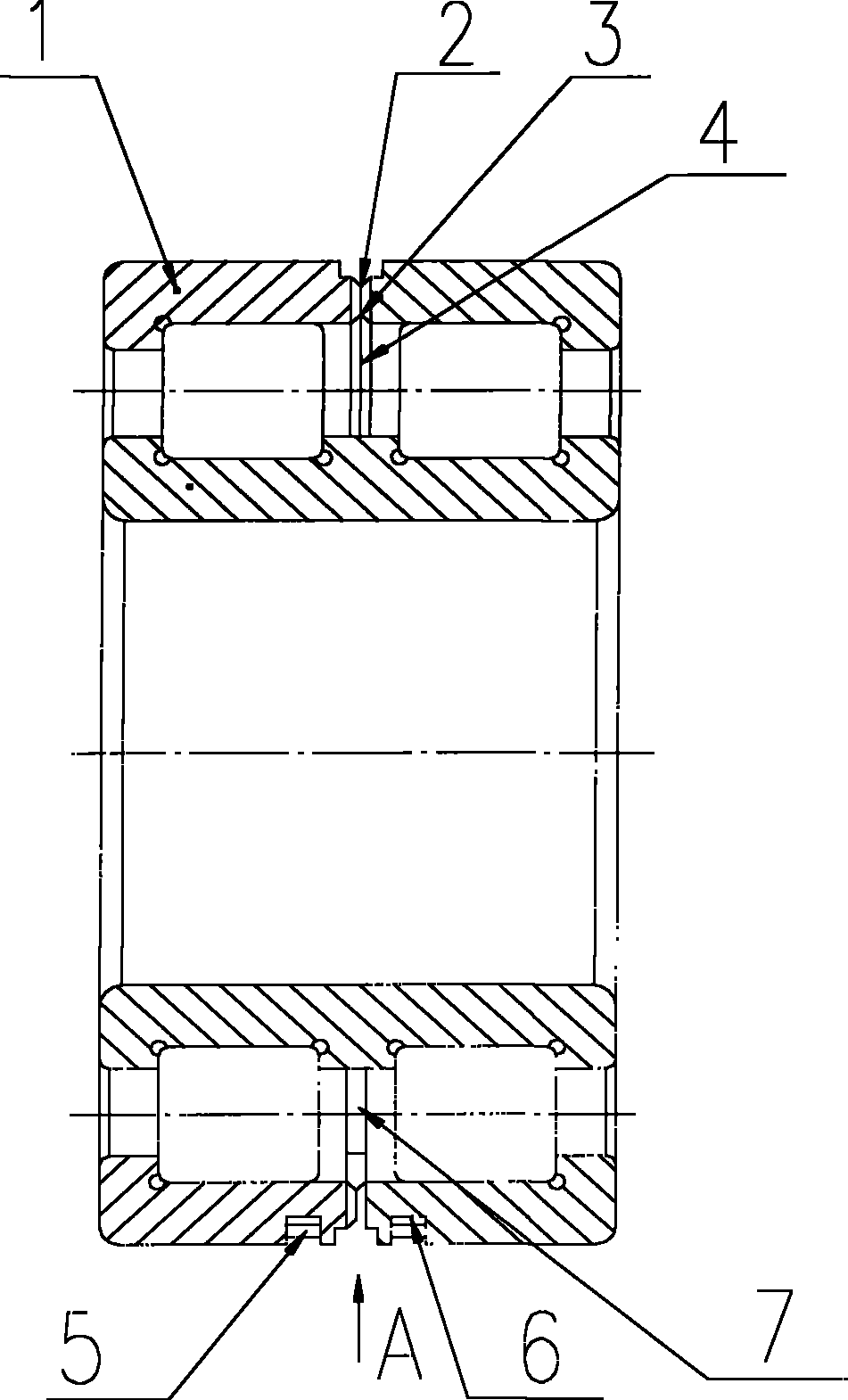

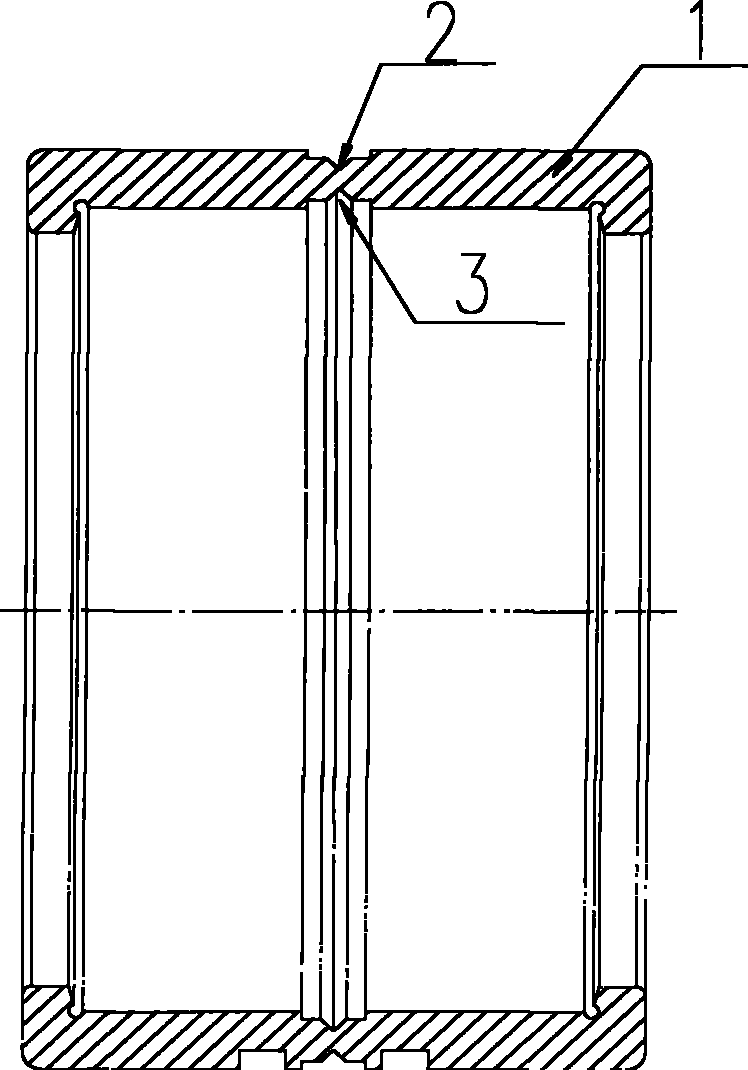

[0020] In conjunction with accompanying drawing, process of the present invention is described in detail:

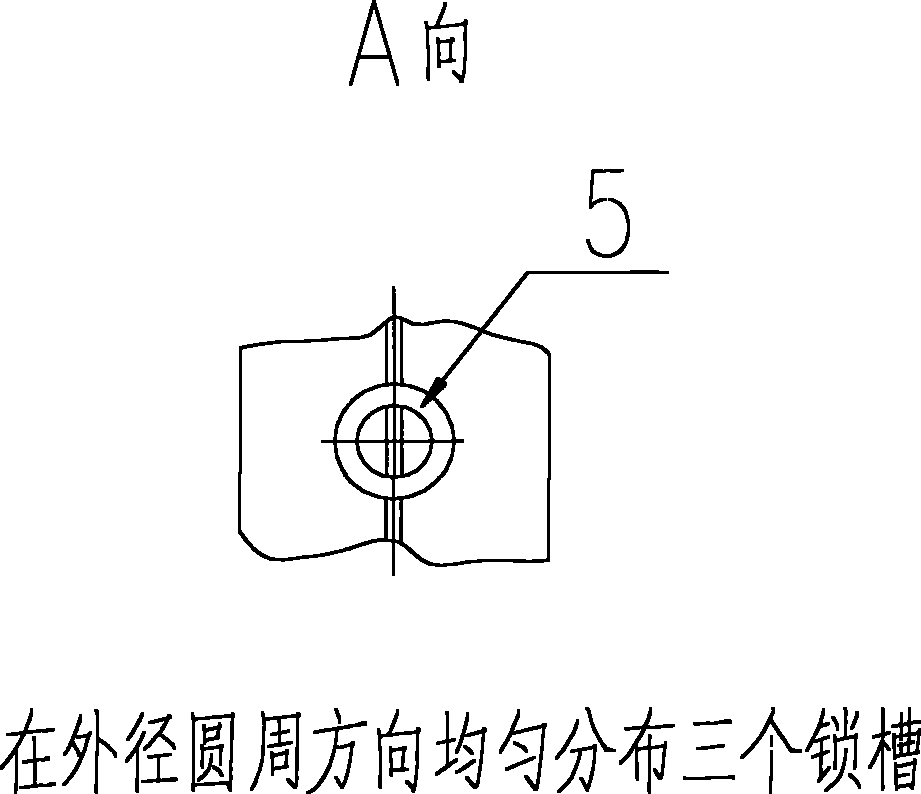

[0021] as attached image 3 As shown, during lathe processing, 4 ring-shaped process guide grooves 2 and 3 are opened on the middle position of the outer diameter generatrix of the SL01 type split bearing outer ring 1 and on the relative position of the raceway (the position to be cut), and the opened guide grooves 2, 3 perpendicular to the axis of the bearing; as attached Figure 4 As shown, after the grinding process is completed, a transverse incision 7 is made by wire cutting along the guide groove. The length of the incision depends on the size of the bearing diameter, which is about 1 / 8 of the circumference of the bearing outer ring; Apply a certain force to divide the outer ring into two to realize splitting. After the product is assembled, it is docked according to the original interface, and then three lock rings 5 are respectively installed in the three loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com