Flow sensor unit

A technology of flow sensor and sensor chip, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, instruments, etc., can solve the problems of flow sensor 1 output characteristic deterioration, detection accuracy deterioration, etc., to avoid detection accuracy deterioration, output Not easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

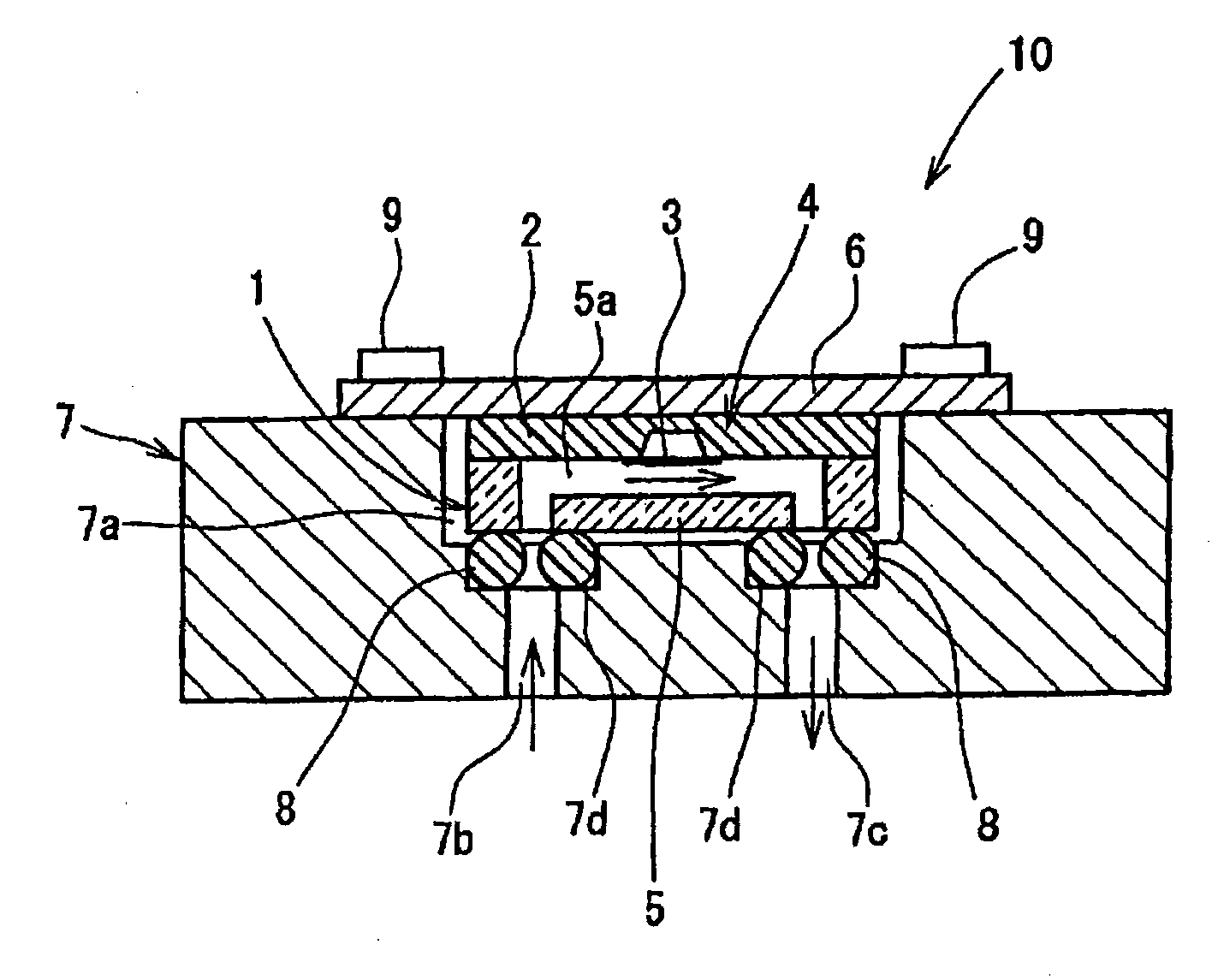

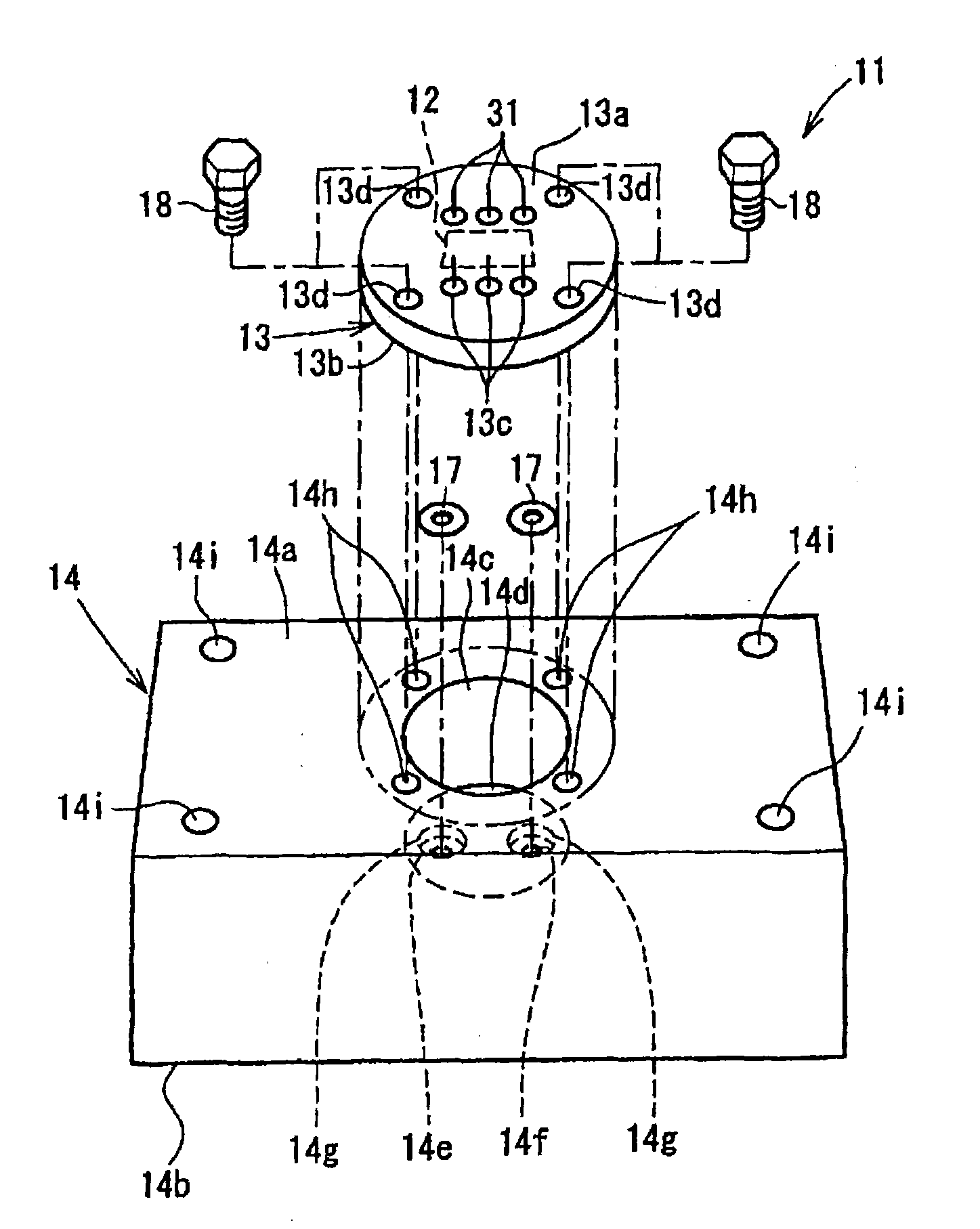

[0030] Hereinafter, a flow sensor unit according to one embodiment of the present invention will be described with reference to the drawings. figure 2 is an assembled perspective view of a flow sensor unit according to an embodiment of the present invention.

[0031] The flow sensor unit 11 is composed of the following components: a thermal flow sensor 12 indicated by a dotted line, which is used to detect the flow rate of the fluid to be measured; a mounting plate 13 made of metal, which is fixed on its lower surface (inner surface) and maintains the flow rate. sensor 12; and a flow channel body 14 made of metal, which is formed with a hole 14c for accommodating the flow sensor 12, a fluid introduction channel 14e, and a fluid discharge channel 14f, and the flow channel body 14 accommodates the flow sensor 12 and fixes the mounting plate 13 .

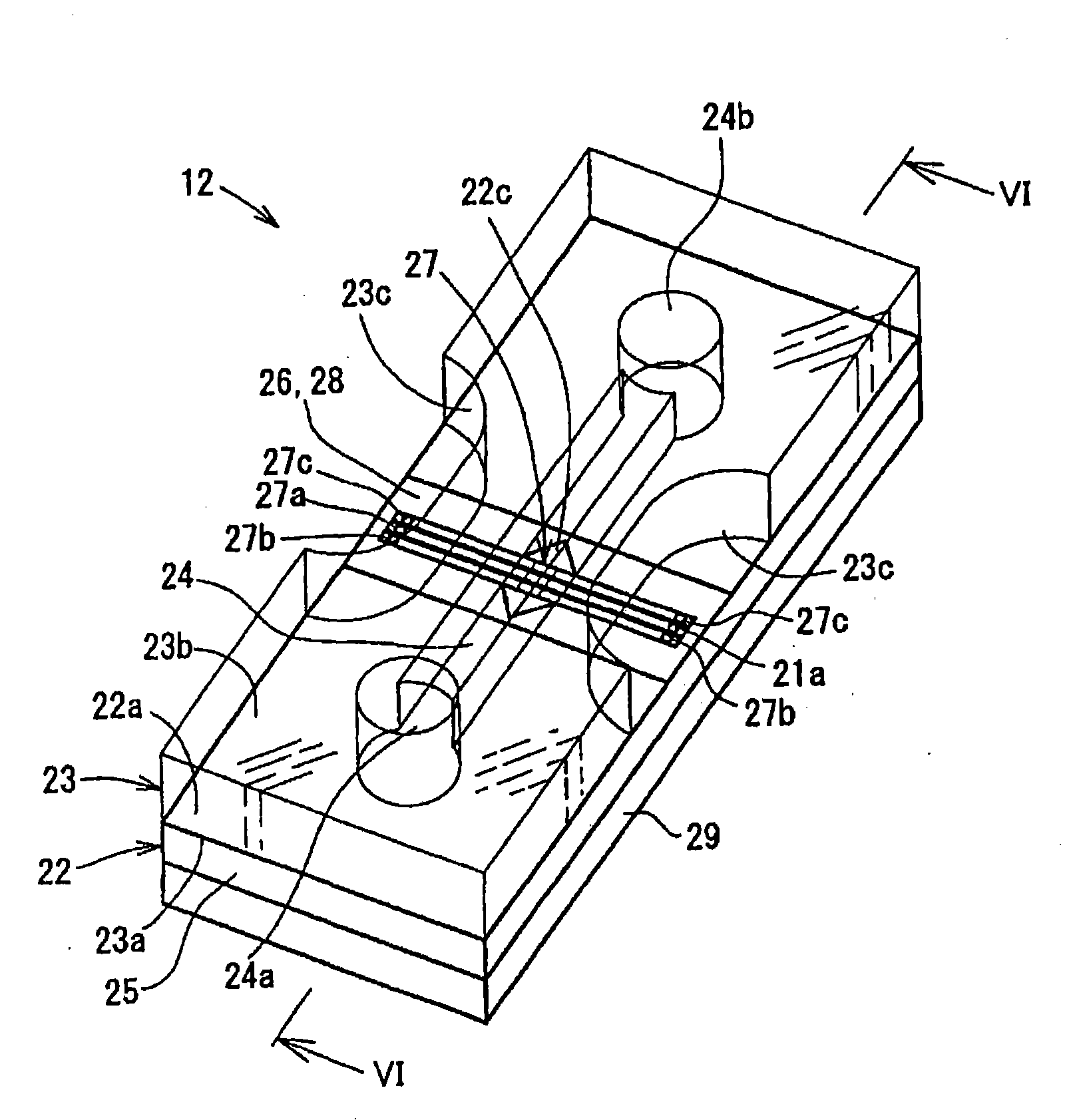

[0032] like image 3 As shown, the flow sensor 12 is composed of the following components: a flow sensor chip 22; a transparent gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com