Flow sensor and manufacturing method therefor

A flow sensor and sensor chip technology, which is applied in the field of flow sensors, can solve the problems of poor alignment accuracy of flow sensors, increased manufacturing costs of flow sensors, and high cost of laser cutting devices, so as to achieve stability, product qualification rate, Effect of avoiding deterioration of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

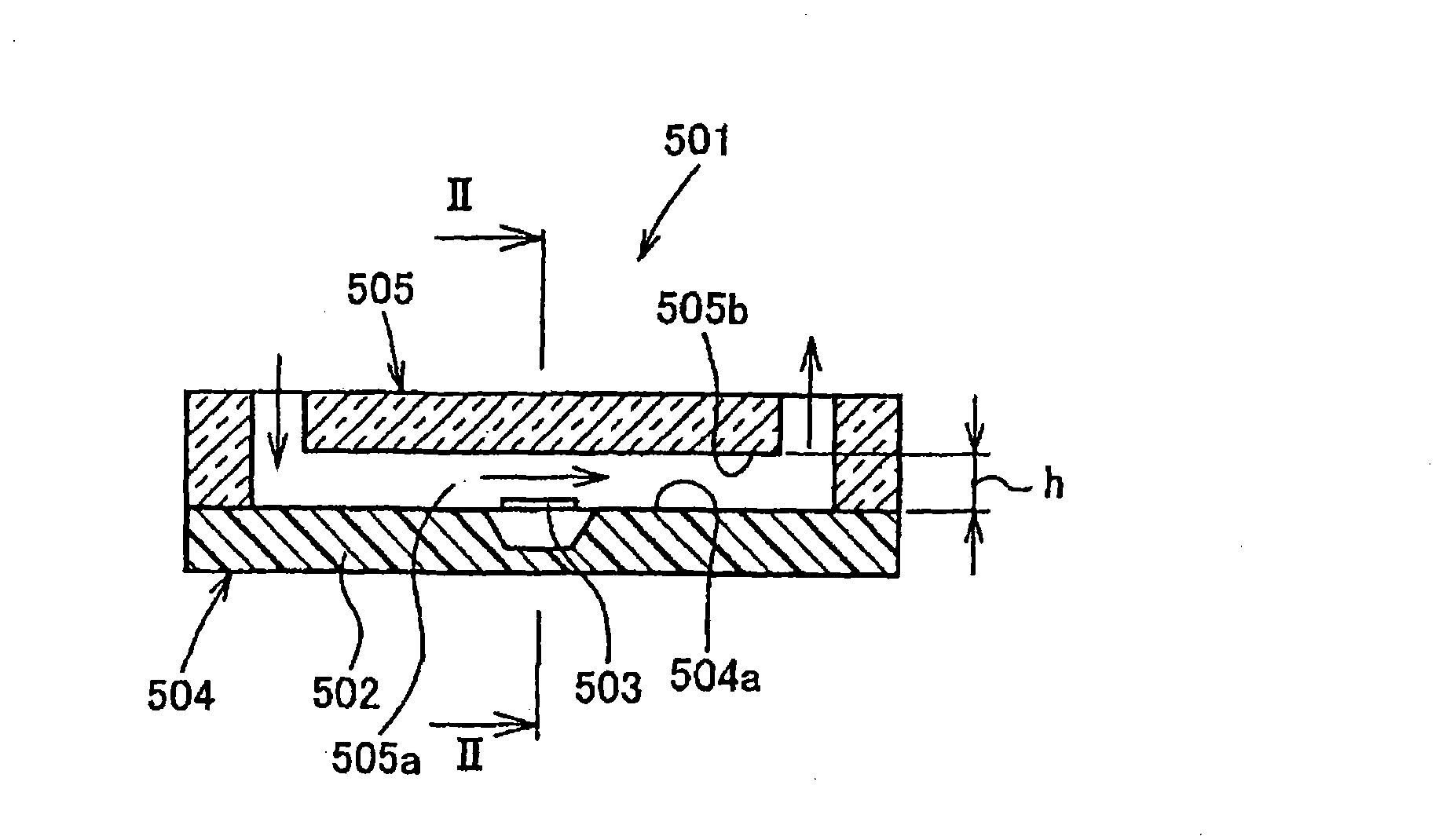

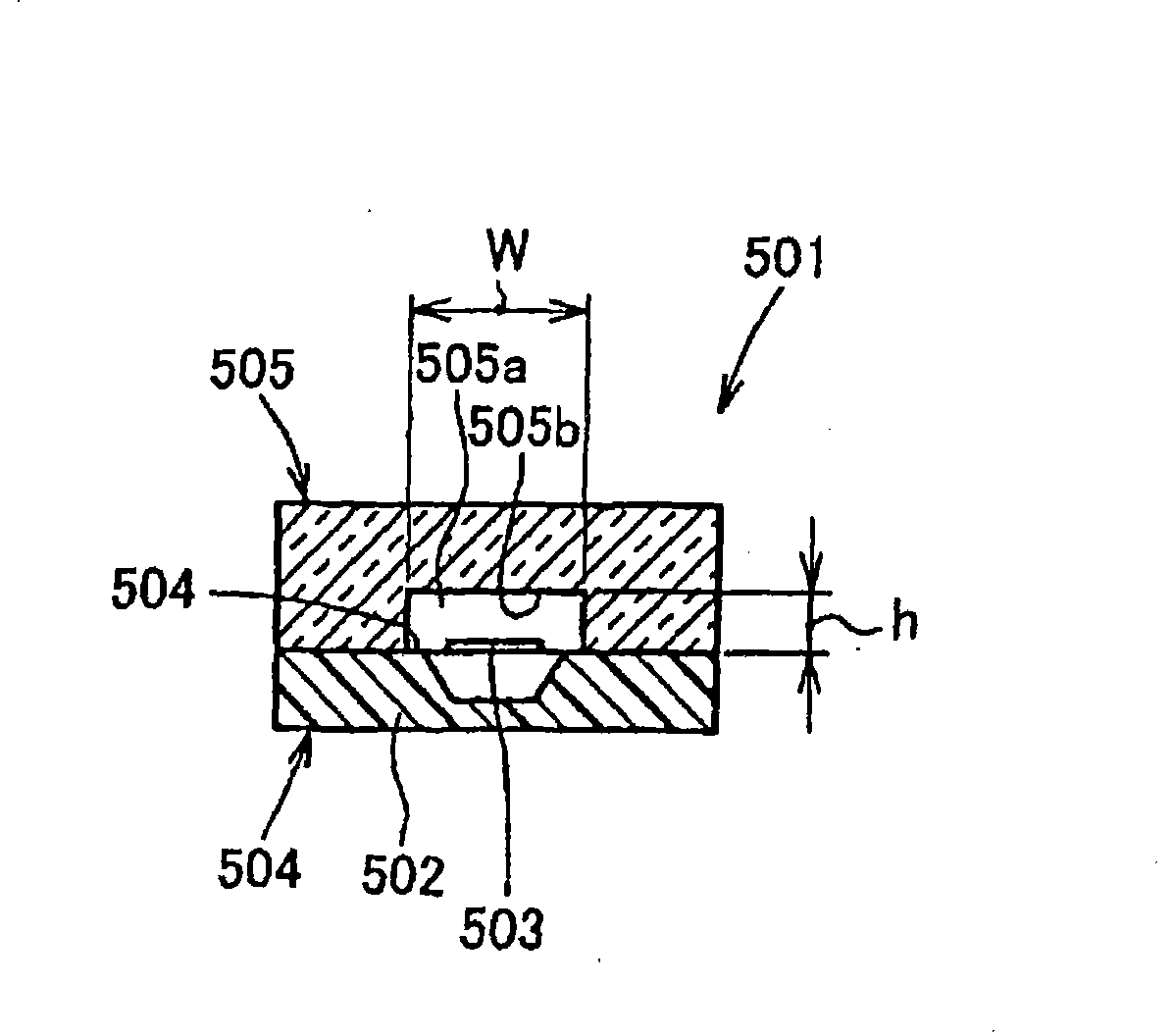

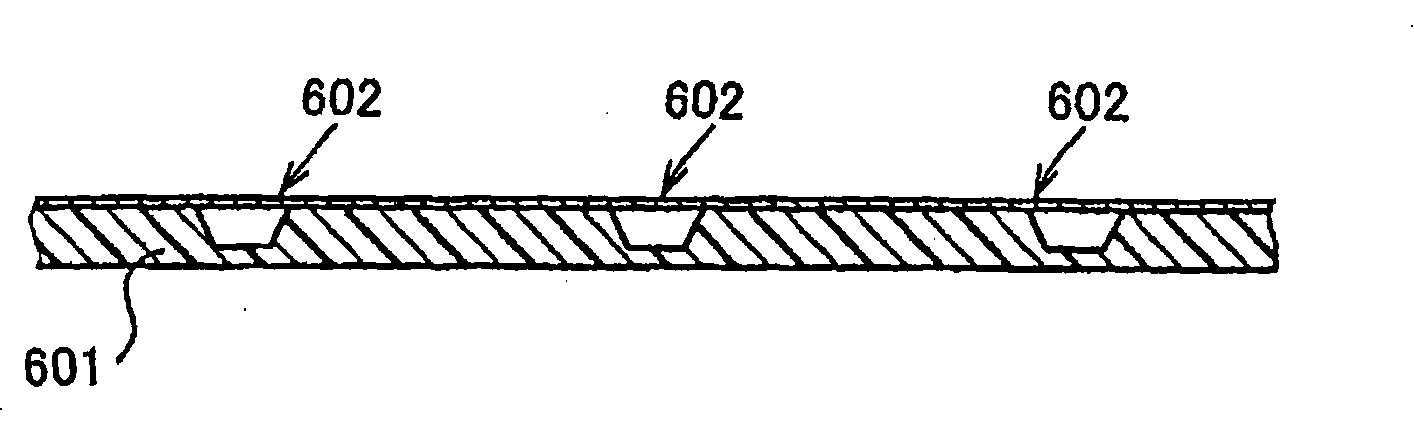

[0088] As described above, according to the first embodiment of the present invention, the transparent plate-shaped first flow path forming member and the second flow path forming member are joined together to form the flow path forming member, and the first flow path forming member is formed with The inlet hole and the outlet hole of the fluid; the above-mentioned second flow channel forming member is formed in a plate shape, and a through hole is arranged on it, and the through hole forms a flow channel along the flow of the fluid, and the fluid is arranged on the sensor chip along the flow through the flow detecting part, make the two ends of the through port (flow channel) communicate with the inlet hole and the outlet hole respectively, form a flow channel with a predetermined cross-sectional area of the flow channel, and arrange the flow detecting part in the through port, thereby, can The height of the sensor flow path, that is, the cross-sectional area of the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com