Escalator or moving walkway

A technology for moving walks and escalators, applied in escalators, transportation and packaging, etc., can solve the problem of large sprocket or supporting wheel layout, and achieve the effect of reducing the structure width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

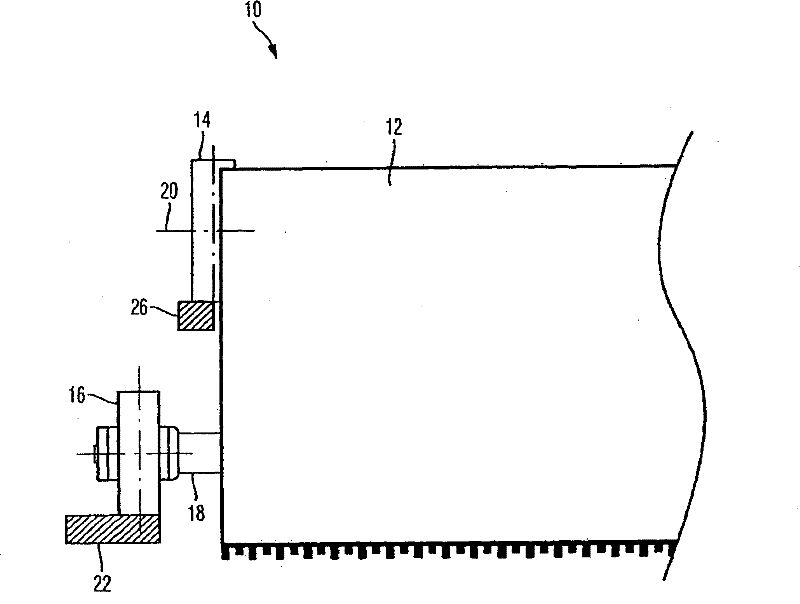

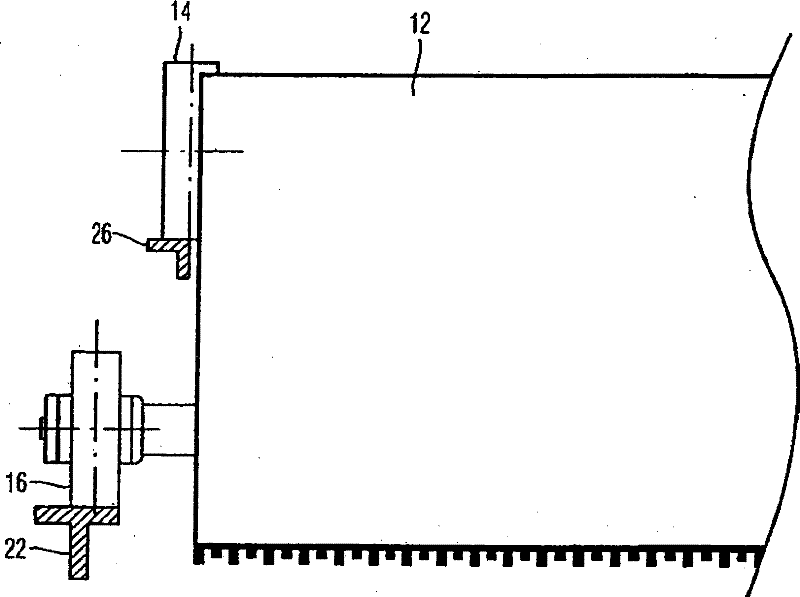

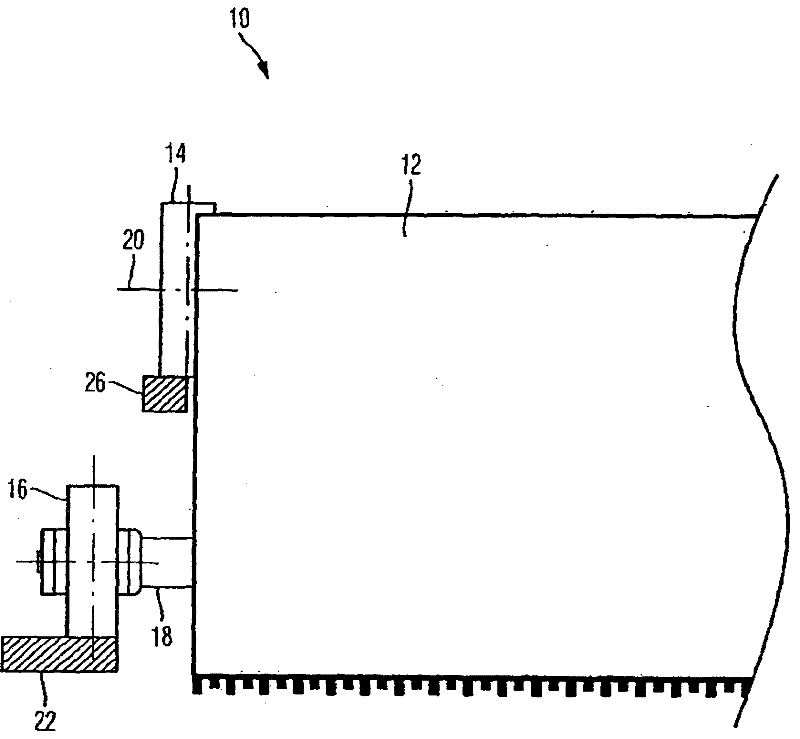

[0017] The escalator 10 according to the invention has escalator steps, in figure 1 One of the escalator steps 12 is shown in . Each step has a support wheel 14 and a sprocket 16 on each side, which are each mounted on a journal. The journal 18 of the sprocket 16 can be obtained from figure 1 As can be seen in FIG. 1 , the relevant journal of the bearing wheel 14 is covered by the view of the step 12 and is represented only by the schematically indicated axis 20 of the bearing wheel 14 .

[0018] The sprocket 16 is supported via a sprocket rail 22 in a known manner. The sprocket track 22 extends laterally far enough outside and has a desired width and is significantly wider than the sprocket 16 . sprocket 16 in accordance with figure 1 The case is supported on the inner half of the rail 22 , that is, the half facing the step 12 .

[0019] Support wheel 14, in accordance with figure 1 In a suspended view of the escalator step 12 protrudes slightly, for example by about on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com