Spiral movable feeding system

A feeding system and screw technology, applied in the field of automatic feeding system, can solve the problems of low egg-to-material ratio and uneven feeding, and achieve the effects of uniform quality, consistent feeding effect, and improved egg-to-material ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

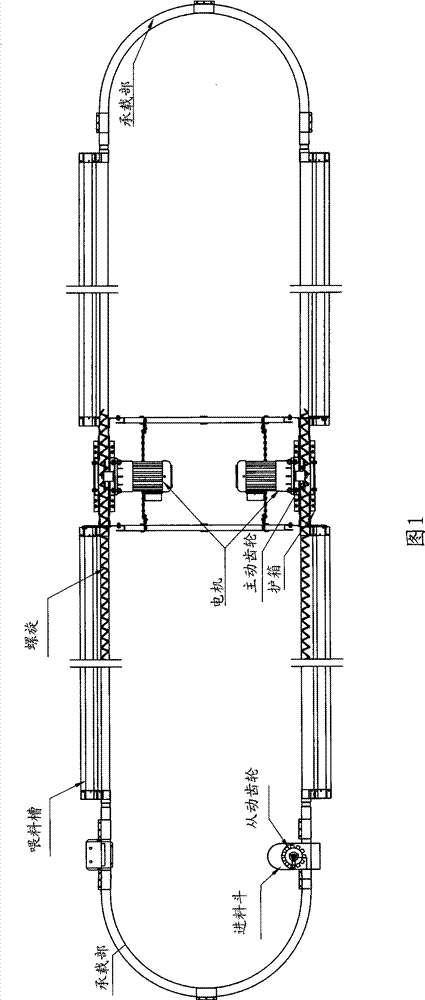

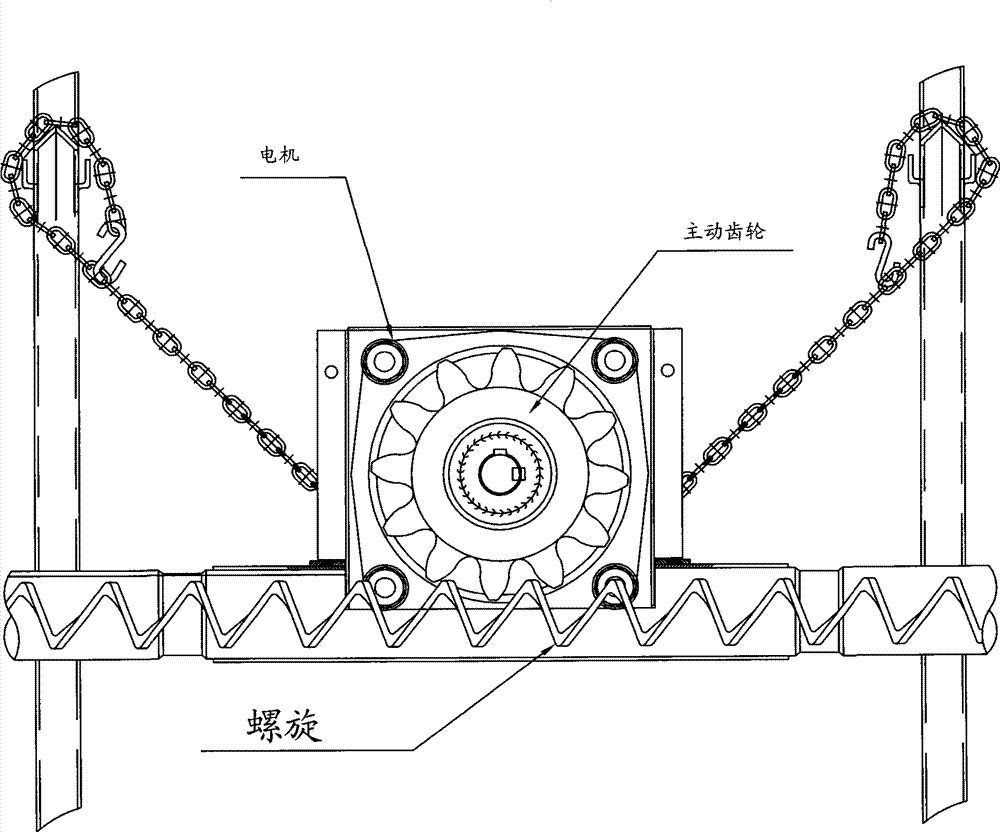

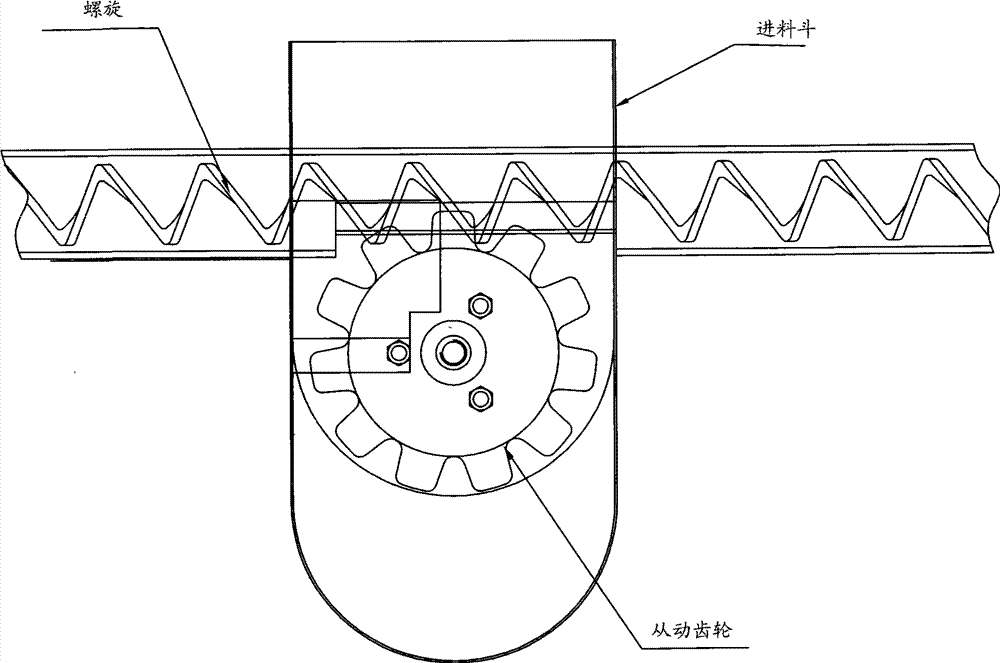

[0029] see figure 1 , 2 3. As shown in the figure, the feeding system includes: a screw with closed ends, a feeding hopper, a load bearing part, a power mechanism composed of a driving gear and a motor connected to the driving gear.

[0030] The helix can be, but not limited to, drawn by 60SimoA steel wire and heat-treated, and has better strength and toughness.

[0031] The outer diameter of the spiral used in this embodiment is not less than 36 mm and not greater than 42 mm, the inner diameter is not less than 20 mm and not greater than 30 mm, the thickness is not less than 3.8 mm and not greater than 4.5 mm, and the pitch is not less than 30 mm and not greater than Greater than 35 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com