Horizontal type spraying machine

A shotcrete machine, horizontal technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of difficulty in entering concrete into the material cavity, increase the feeding time, reduce the work efficiency, etc., and shorten the material feeding. time, improve work efficiency, shorten the effect of feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

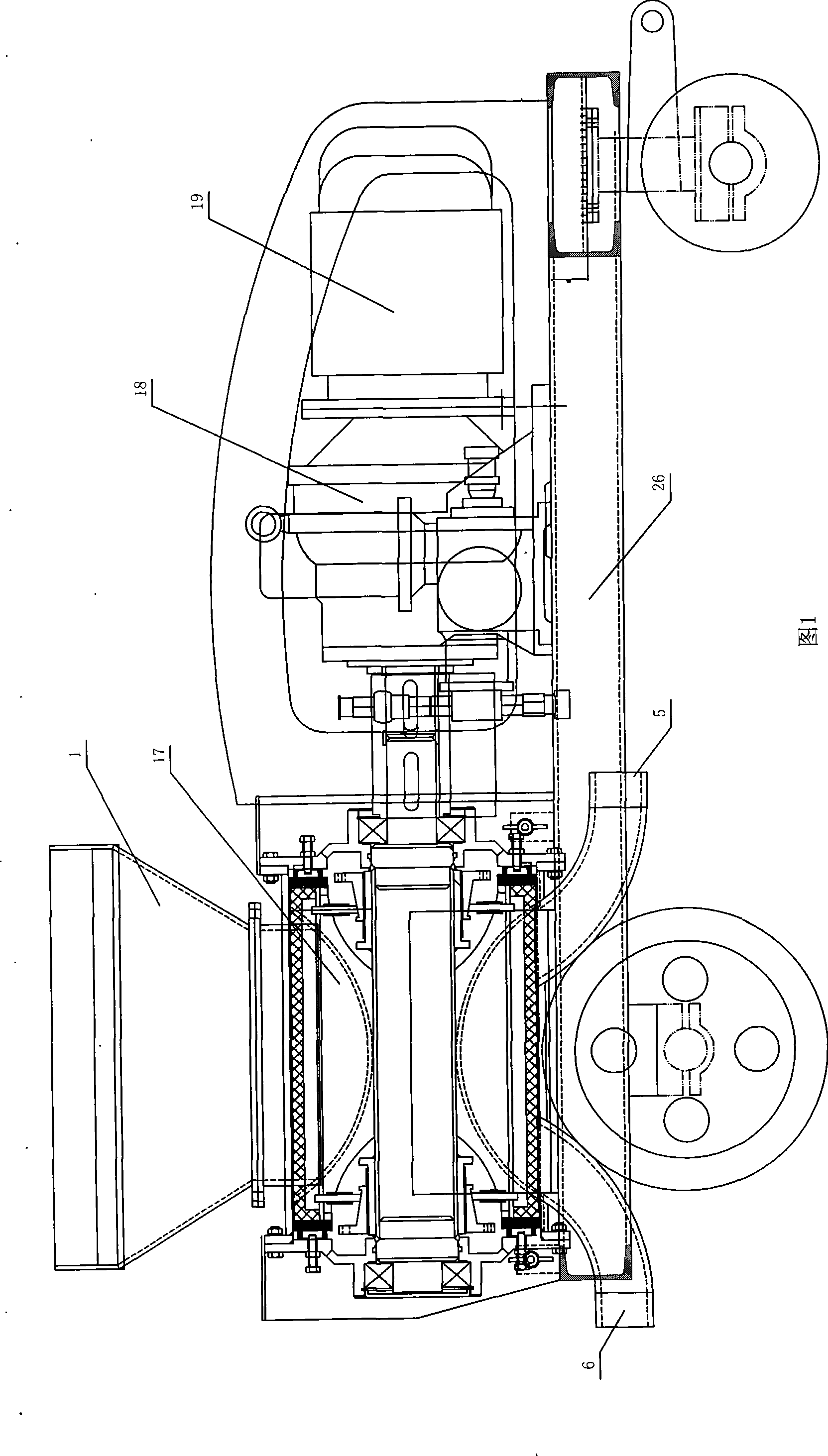

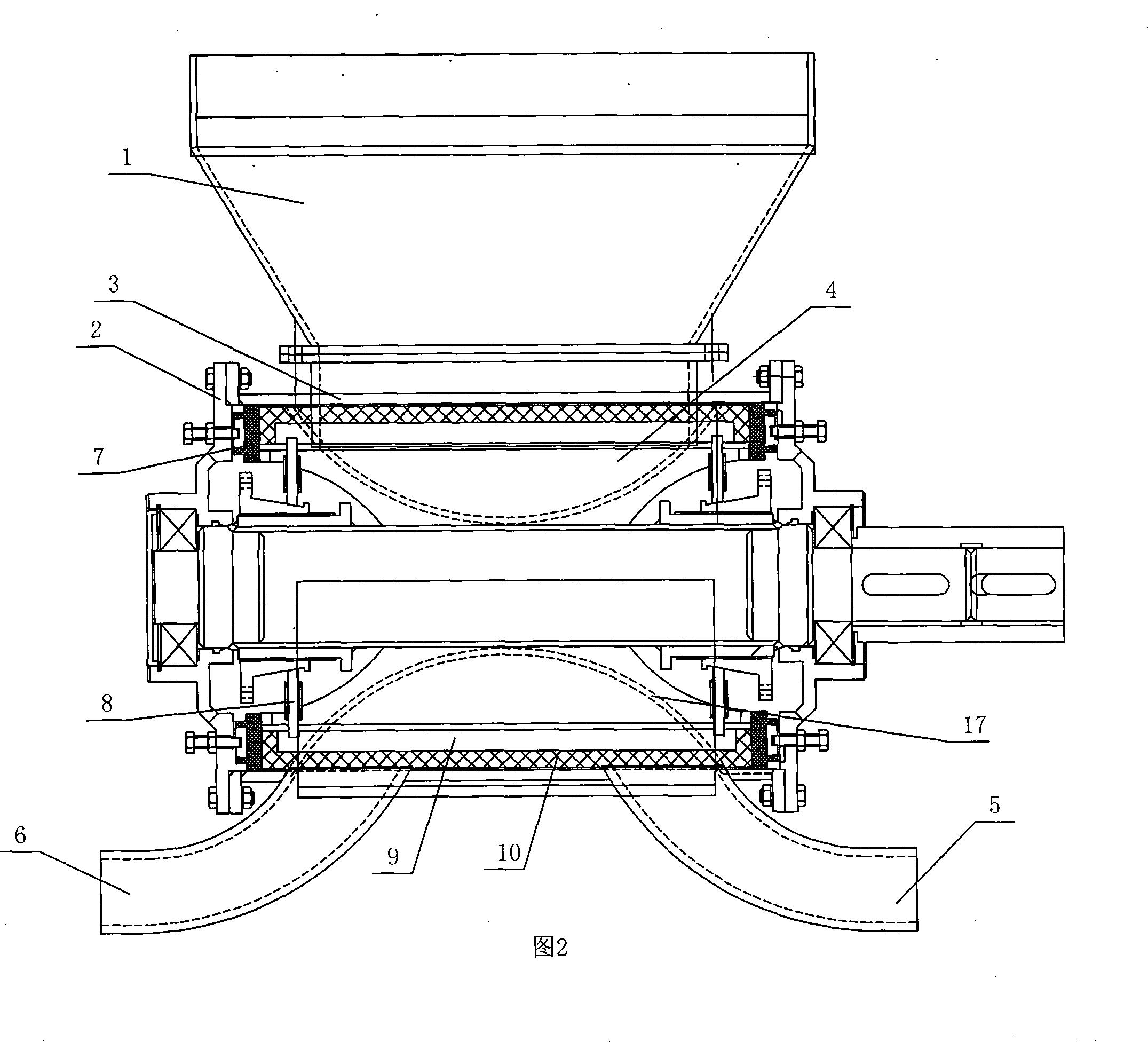

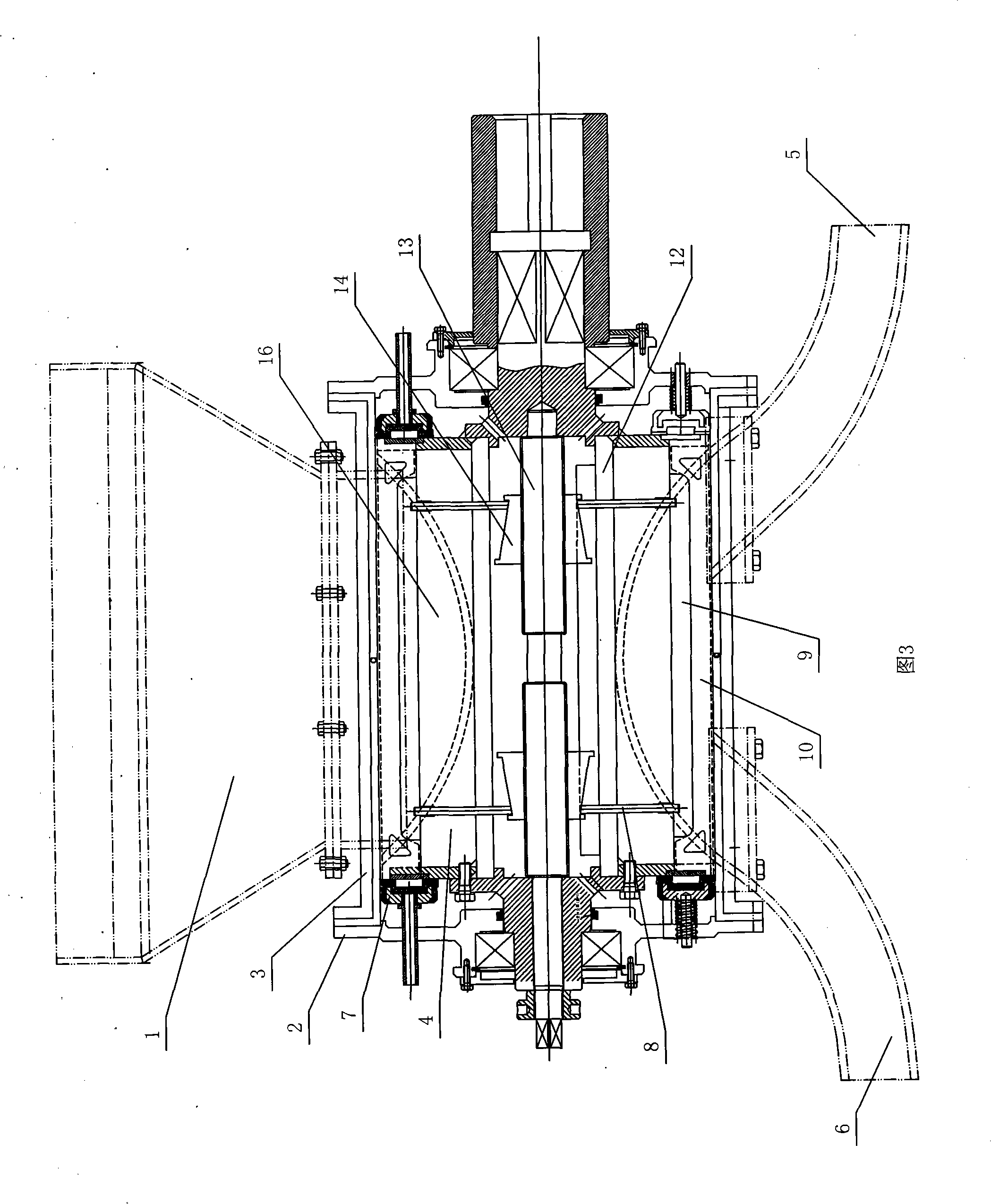

[0024] like figure 1 The shown horizontal shotcrete machine comprises a vehicle frame 26, a feeding host 17 and a hopper 1 arranged on the top of the feeding host 17, and the feeding host 17 includes a stator 3 and a rotor 4 arranged transversely on the frame 26, and the rotor 4 cylinders are provided with material grooves 16 at intervals; a hopper 1 is arranged above the stator 3, and the lower opening of the hopper 1 communicates with the inner cavity of the stator 3 and its position corresponds to the position of the material groove 16 on the rotor 4; The air inlet 5 and the air outlet 6 connected to the cavity and the opening position correspond to the position of the single material groove 16 on the rotor 4. The air inlet 5 communicates with the gas output port of the high-pressure gas generating device, and the rotor 4 shaft is connected to the air outlet through the reducer 18. The electric motor 19 is transmission connected.

[0025] A circumferential seal is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com