Hook and support assembly

A hook and shoulder technology, which is applied in the directions of portable mobile devices, hooks, travel or camping equipment, etc., can solve the problems of complicated and troublesome operation, and achieve the effect of simplifying operation, improving service life and minimizing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

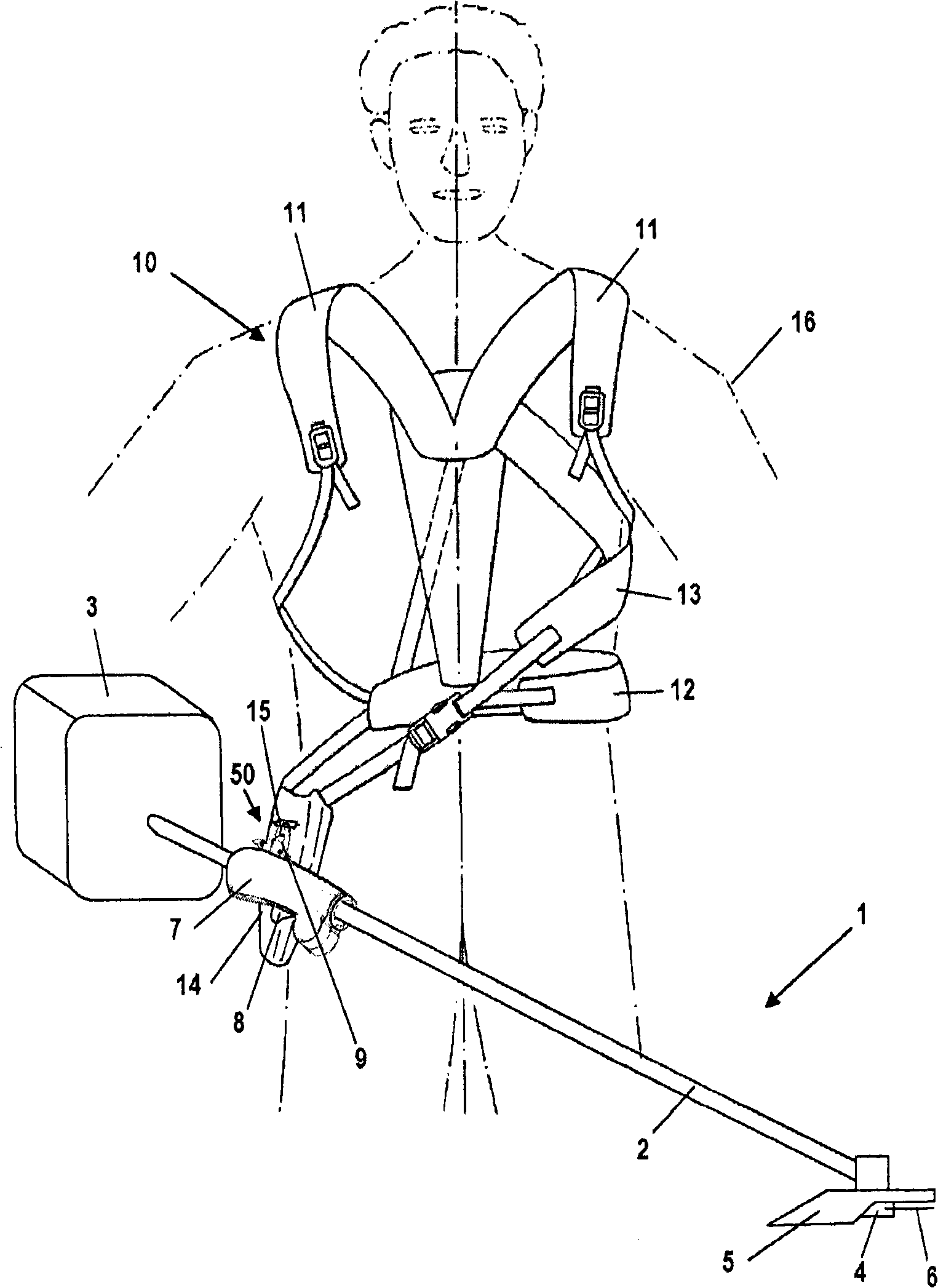

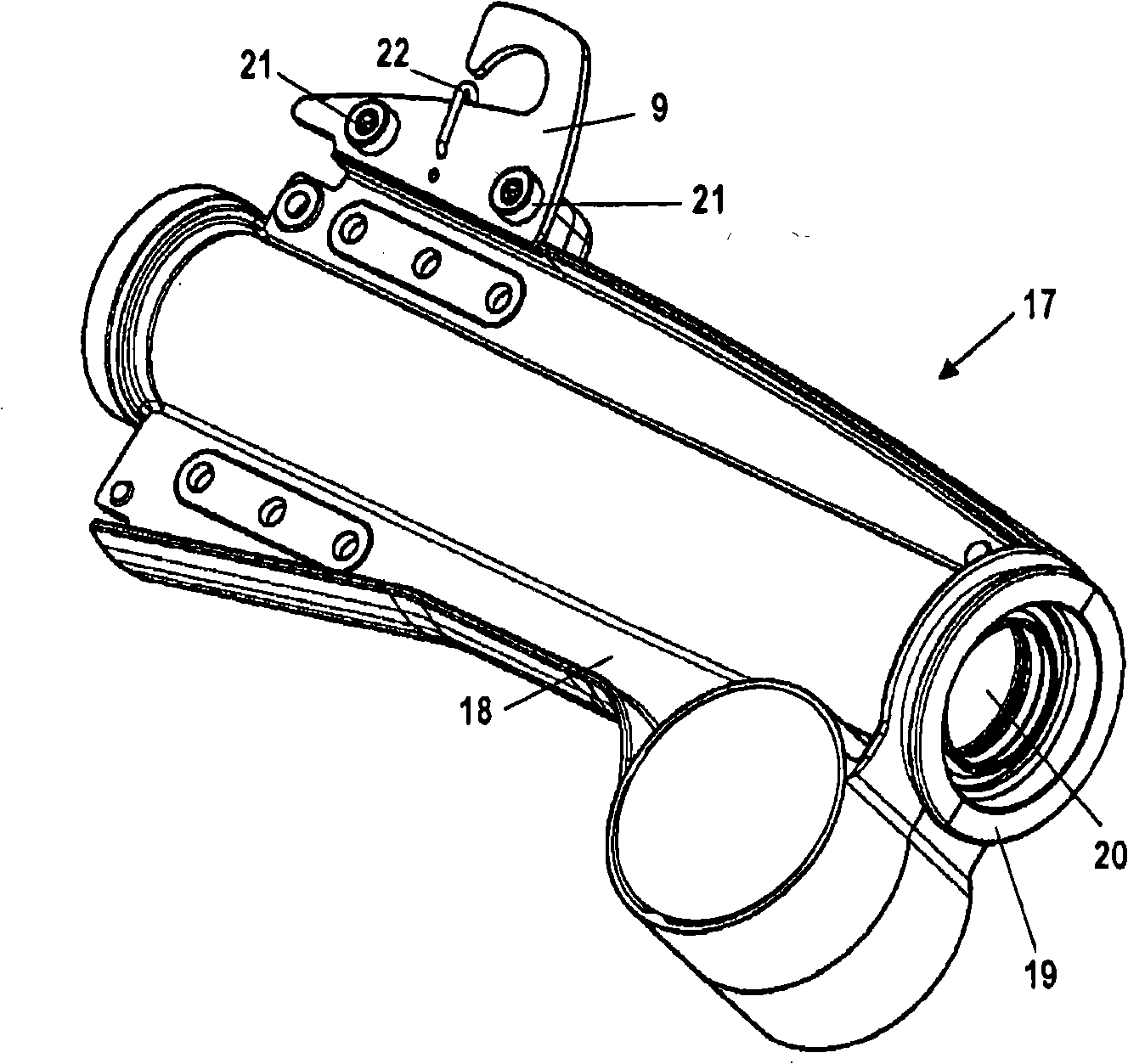

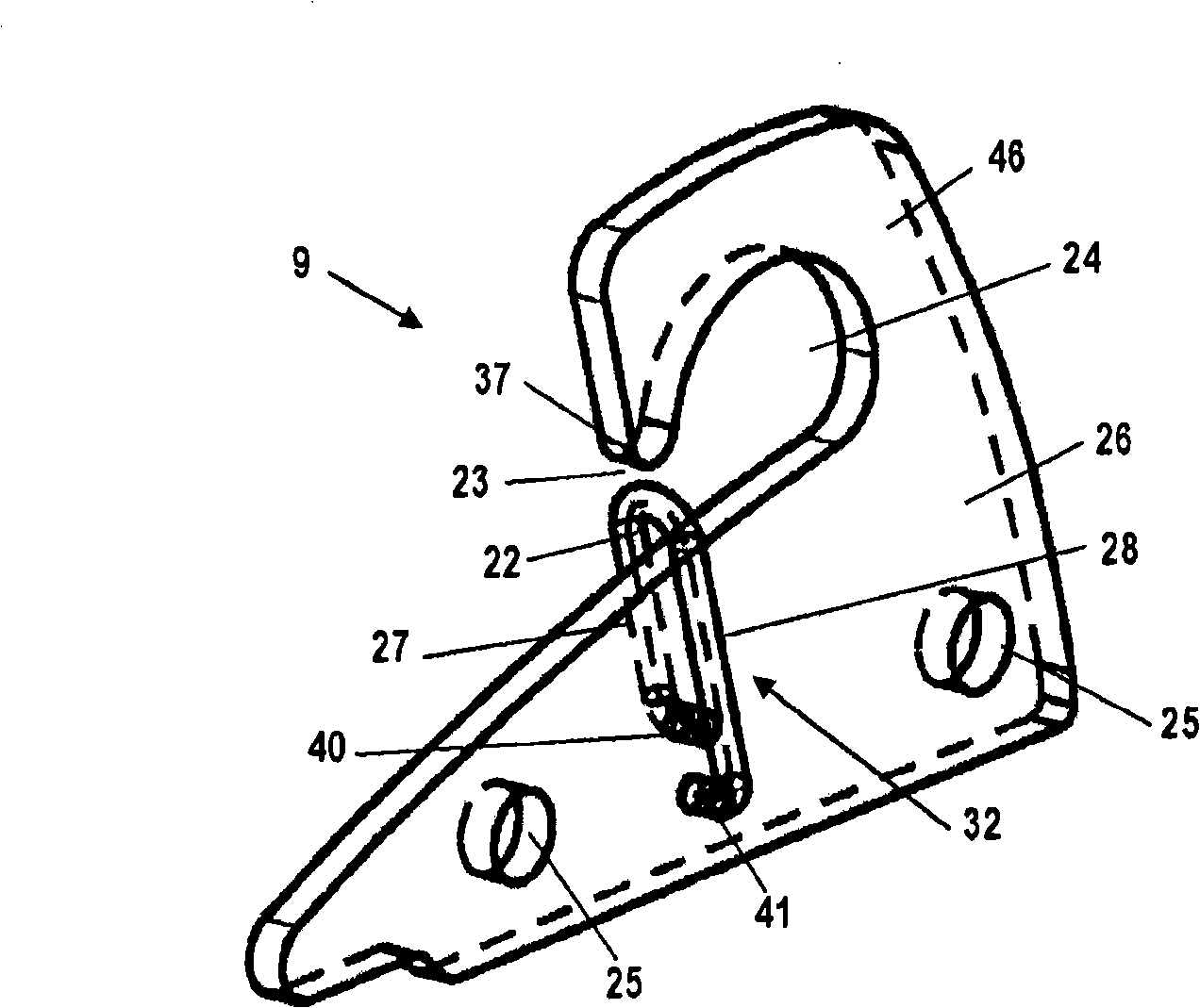

[0028] figure 1 The shoulder-back device shown comprises a belt device 10 , a fastening device 50 and a free cutter 1 . Instead of the free cutter 1 , the belt device 10 can also be used for another hand-held power tool, for example a tree splitter, a harvesting tool such as, for example, an olive shaker or the like. The free cutter 1 includes a guide tube 2, a motor housing 3 is provided at one end of the guide tube and a silk harvesting head 4 is provided at the opposite end. A harvesting wire 6 protrudes from the silk harvesting head 4 , which forms the tool of the free cutter 1 . The movement path of the cutting wire is covered by a guard plate 5 on the side directed towards the operator 16 . A drive motor, not shown, which can be, for example, a two-stroke engine or a mixed-lubrication four-stroke engine is located in the engine housing 3 . However, the drive motor can also be an electric motor. The drive motor drives a drive shaft which is rotatably arranged in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com