Wiper pressing force test device and method

A test device and wiper technology, which is used in measurement devices, machine/structural component testing, vehicle testing, etc., can solve the problems that height cannot be well controlled and cannot be measured accurately, and achieve the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

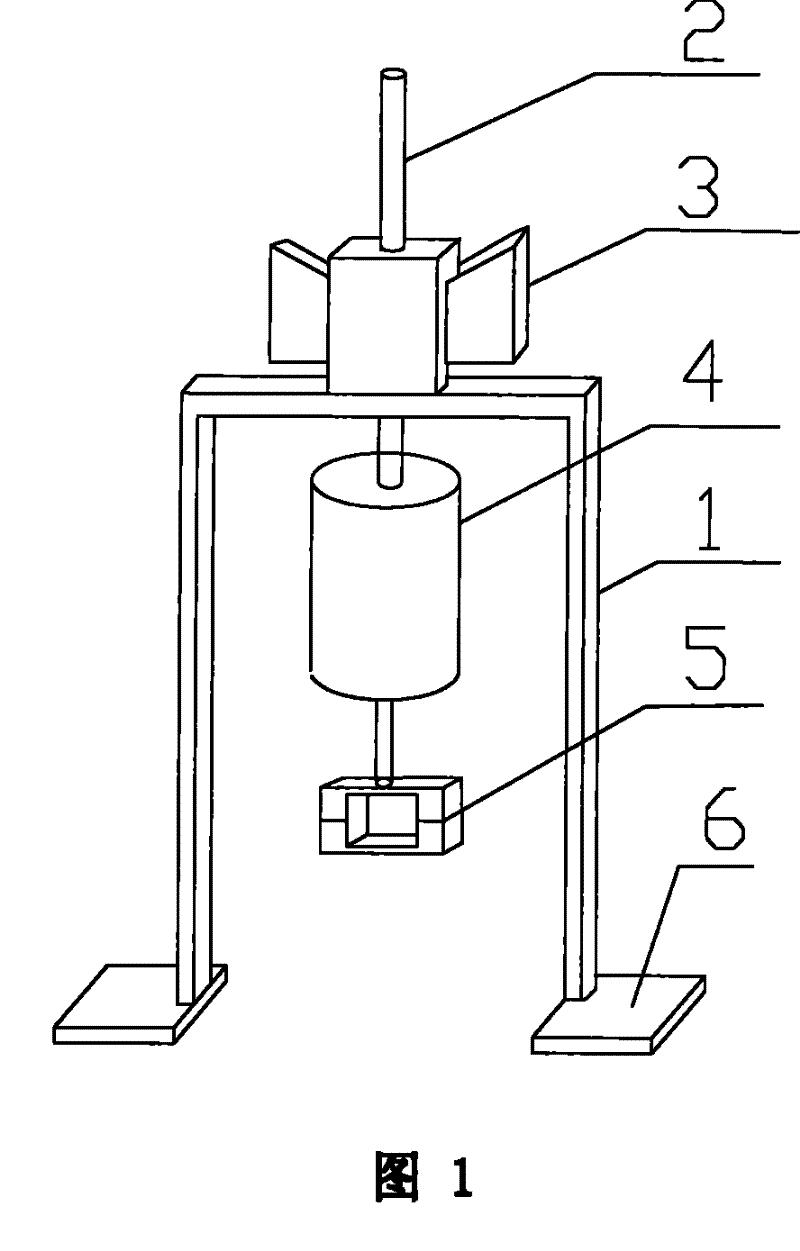

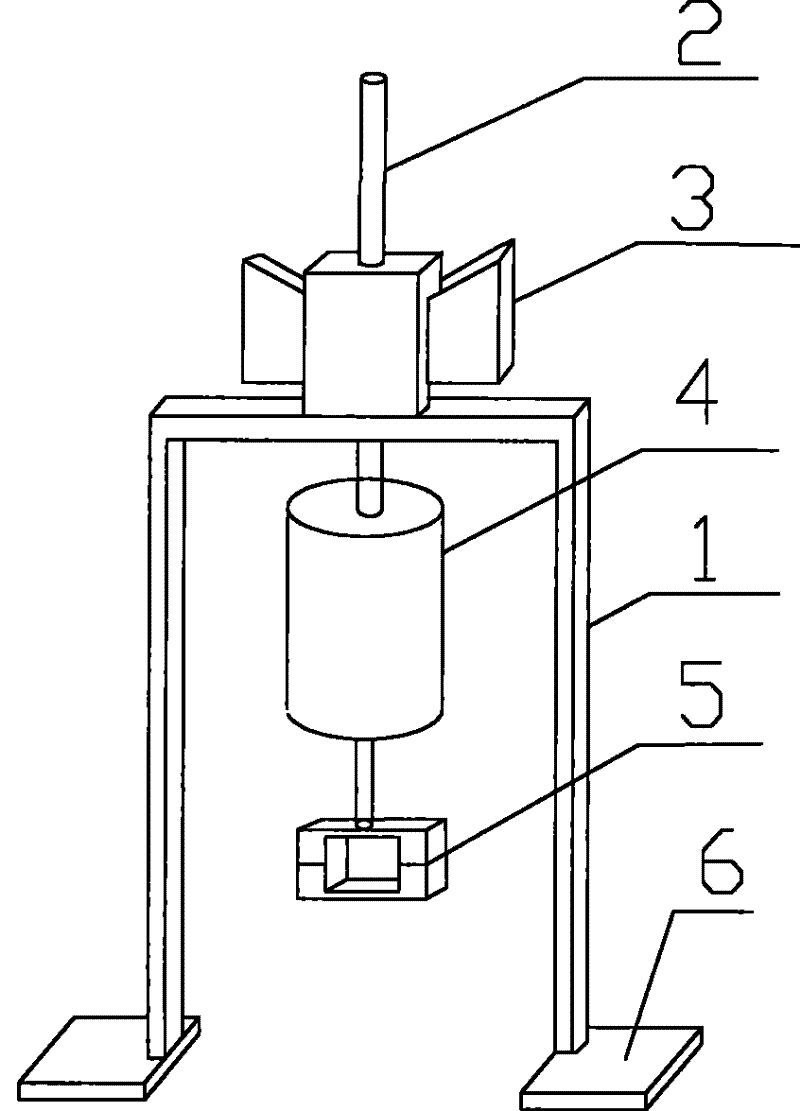

[0015] like figure 1 Shown, a kind of automobile windshield wiper compression force testing device, comprises force sensor 4, the clip 5 of clamping wiper; Also be provided with a door-shaped frame 1, a guide rail hole is arranged on the door-shaped frame 1 doorframe, passes through a guide rail hole The screw rod 2 can only slide up and down and cannot rotate. The upper part of the screw rod 2 has a nut 3 for movable connection, and the lower end is connected with a force sensor 4 and a clip 5 for clamping the wiper. The upper part of the screw rod 2 is a guide rail surface ground flat on both sides, and there are scale marks on the guide rail surface, which can intuitively read the height of the lift. For the convenience of the manual nut 3, the nut 3 is a wing nut. In order to protect the glass, the lower end of the door frame is pasted with a cushion 6, such as a sponge. In order to clamp the wiper conveniently, the clip 5 for clamping the wiper is a sleeve.

[0016] A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com