A laser shock micro-punching device

A technology of laser shock and micro punching, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of reduced forming effect, high cost, low processing efficiency, etc., achieve good fracture quality, improve service life, The effect of improving the quality of the incision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

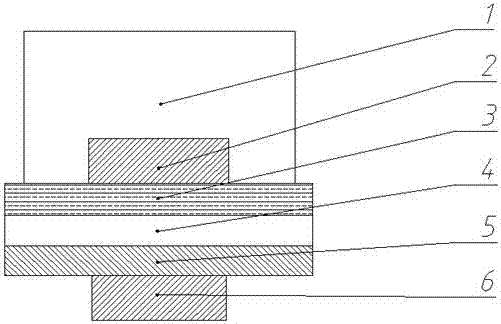

[0020] The pulse width of laser beam 1 described in this example is 10 ns, the highest pulse energy is 0.2 J, and the spot diameter after focusing is 150 μm; the material of mask 2 is copper, the thickness is 0.5 mm, and the shape is a circle with a diameter of 84 μm; the constrained layer 3 is optical glass with a thickness of 0.8 mm; the absorption layer 4 is aluminum foil with a thickness of 50 μm; the metal film 5 is an A304 stainless steel film with a thickness of 100 μm; the material of the lower mold 6 is T7 die steel, and the shape is a cylinder with a diameter of 80 μm .

[0021] After using a laser micro-punching device of the present invention, a large number of A304 stainless steel micro cylinders with a diameter of 80 μm and a height of 100 μm were successfully prepared in large quantities with high dimensional accuracy.

Embodiment 2

[0023] The laser beam 1 described in this example has a pulse width of 10 ns, a maximum pulse energy of 0.3 J, and a spot diameter of 180 μm after focusing; the material of the mask 2 is copper, the thickness is 0.5 mm, and the shape is an equilateral triangle with a side length of 92 μm The constraining layer 3 is transparent resin with a thickness of 0.8 mm; the absorbing layer 4 is black paint with a thickness of 100 μm; the metal film 5 is H62 brass with a thickness of 100 μm; the material of the lower mold 6 is 40Cr die steel, and the shape is side length A triangular prism of 80 μm.

[0024] After using a laser micro-punching device of the present invention, a large number of H62 brass micro-triangular prisms with a diameter of 80 μm and a height of 100 μm were successfully prepared in large quantities with high dimensional accuracy.

Embodiment 3

[0026] The pulse width of the laser beam 1 described in this example is 20ns, the highest pulse energy is 0.8J, and the spot diameter after focusing is 200μm; the material of the mask 2 is copper, the thickness is 0.5mm, the shape is a micro-gear, and the diameter of the indexing circle is 75μm, the number of teeth is 10, and the modulus is 7.5; the constraining layer 3 is transparent resin with a thickness of 1mm; the absorbing layer 4 is black paint with a thickness of 100μm; the metal film 5 is 45 steel with a thickness of 80μm; the material of the lower mold 6 is 20Cr die steel, the shape is a micro-gear, the diameter of the index circle is 60μm, the number of teeth is 10, and the modulus is 6.

[0027] After using a laser micro-punching device of the present invention, a large number of 45 steel micro-gears with high dimensional accuracy, a diameter of 60 μm, a number of teeth of 10, a modulus of 6 and a height of 80 μm were successfully prepared. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com