Apparatus and method of measuring workpieces

A technology for components and sensing equipment, applied in the direction of measuring devices, instruments, etc., can solve problems such as being unsuitable for larger, not always feasible, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

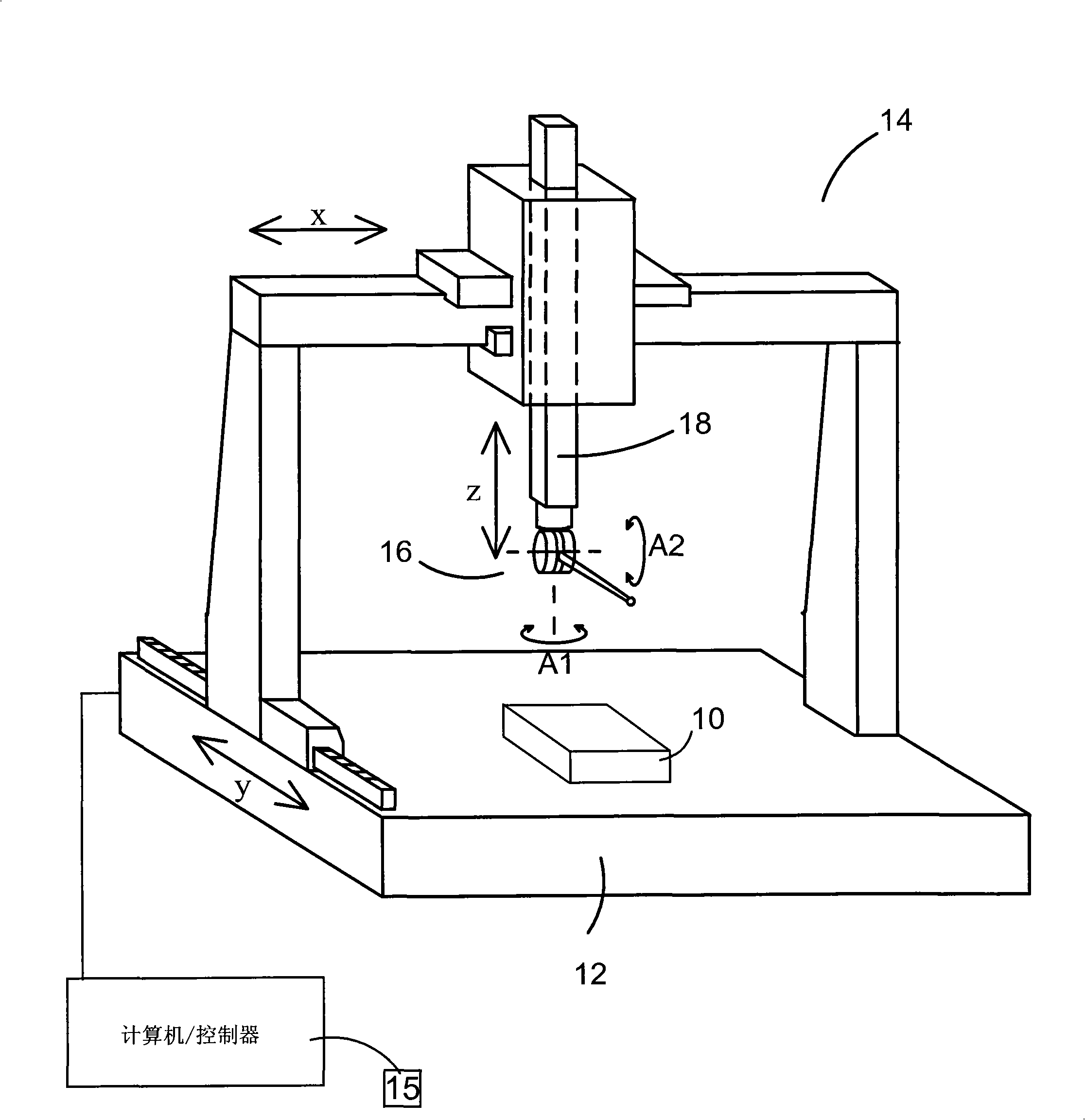

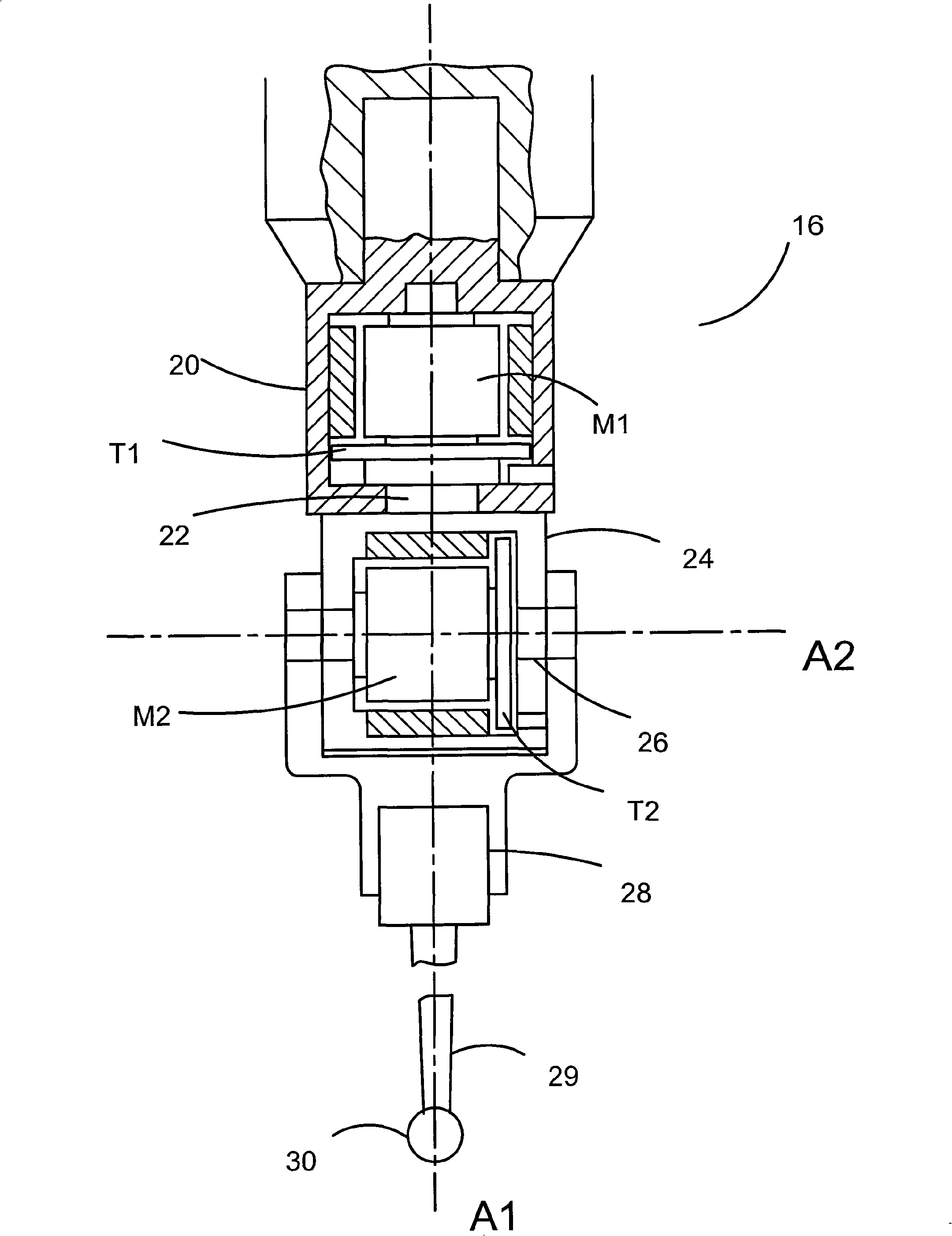

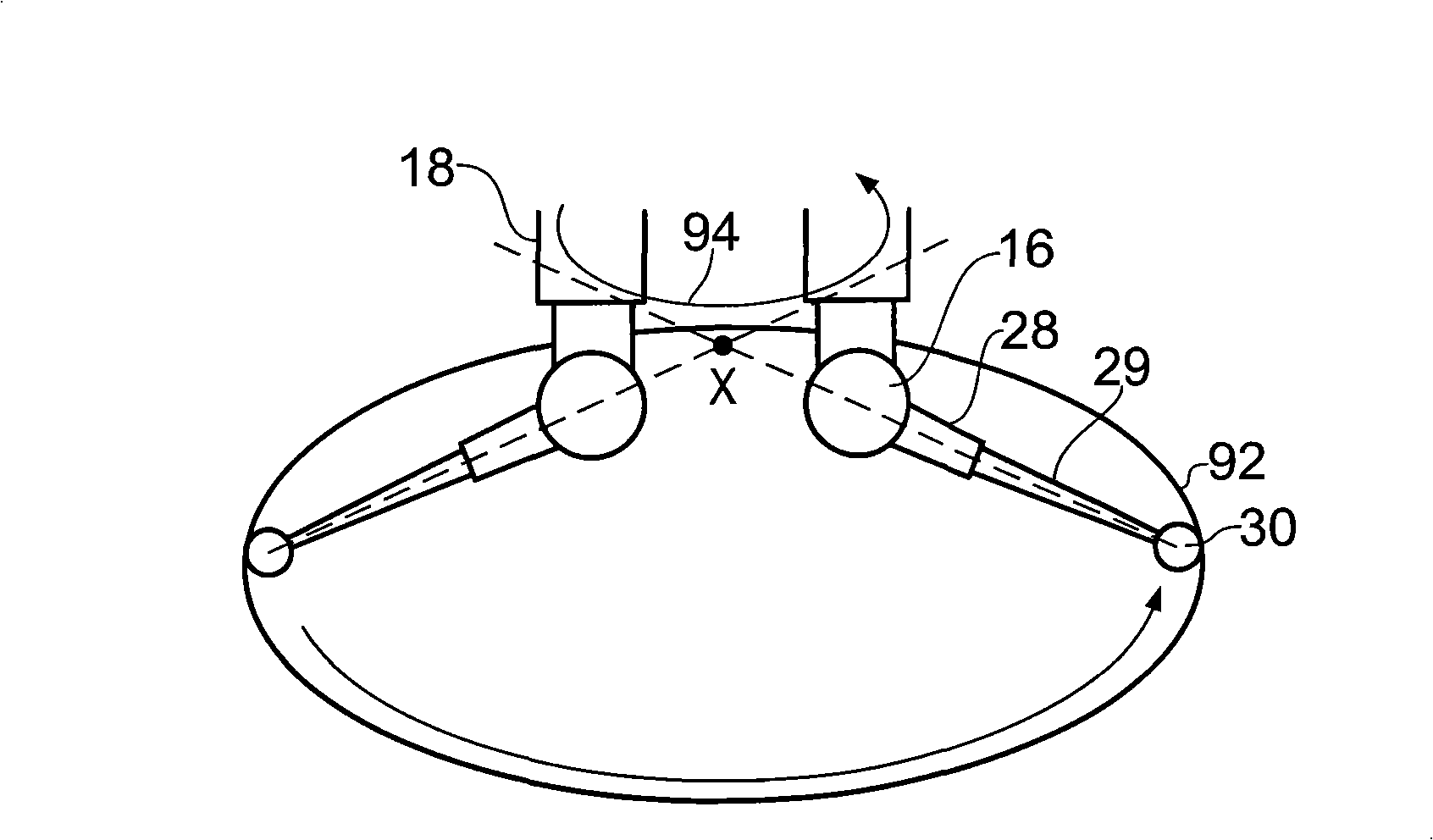

[0037] figure 1 A motorized scanning head is shown mounted on a coordinate measuring machine (CMM). The workpiece to be measured is mounted on the table 12 of the CMM 14 and the motorized scanning head 16 is mounted on the spindle 18 of the CMM 14 . The mandrel can be driven in the X, Y, Z directions relative to the table by means of a motor in a known manner. Such as figure 2 As shown, the motorized scanning head 16 comprises a stationary part formed by a base or housing 20 supported by a moving part in the form of a shaft 22 which is rotatable about an axis A1 relative to the housing 20 . The shaft 22 is fixed to a further housing 24 which in turn supports a shaft 26 which can be rotated relative to the housing 24 by a motor M2 about an axis A2 perpendicular to the axis A1 .

[0038] A probe 28 with a probe 29 having a workpiece contact tip 30 is mounted to the motorized scanning head. This arrangement allows the head's motors M1, M2 to angularly position the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com