High fidelity simulating stratum well-drilling leakage-plugging evaluation experimental system

A technology for simulating strata and an experimental system, which is applied in the field of drilling and can solve the problems of distortion of the properties of the simulated stratum and the actual stratum, and the results of field application are too different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

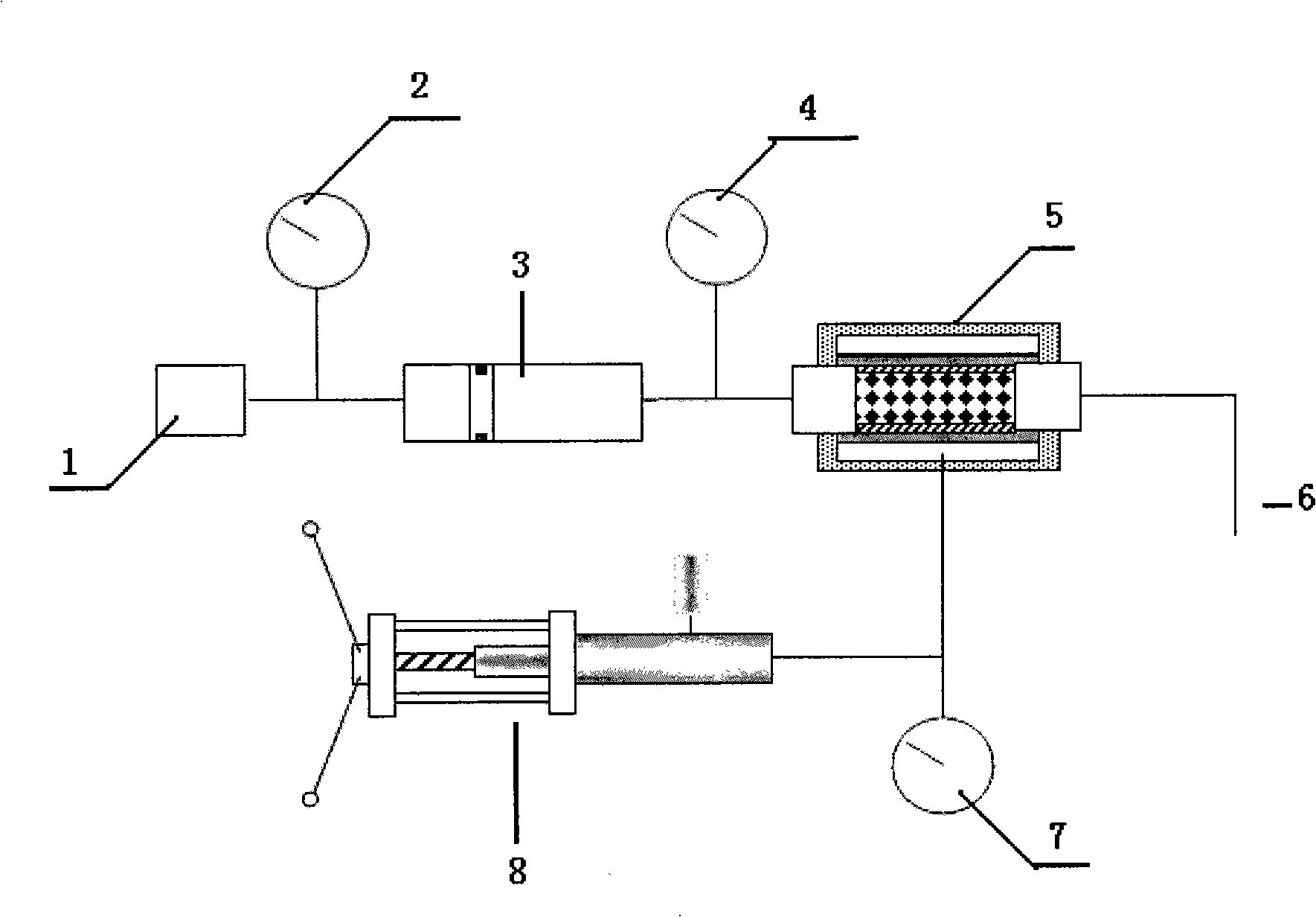

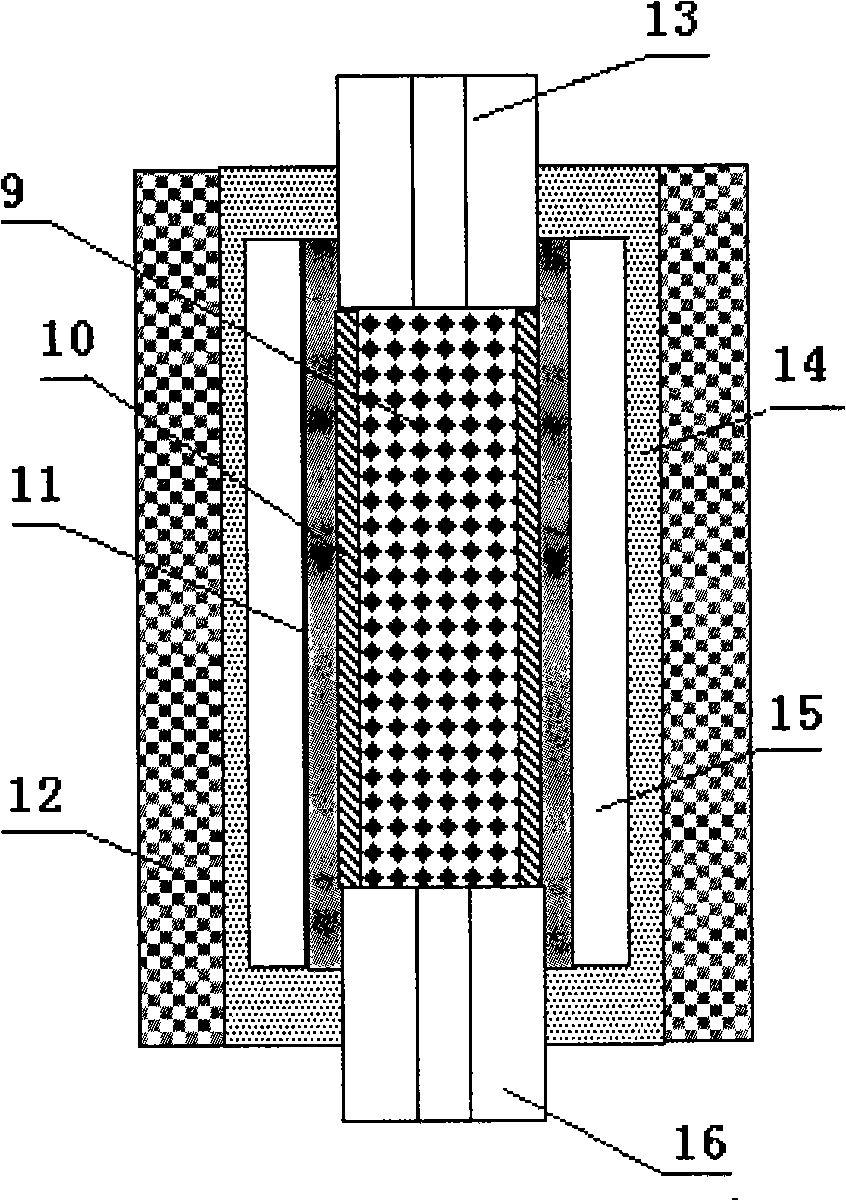

[0022] The structure of the present invention is as figure 1 As shown, the high-fidelity simulated formation drilling plugging evaluation experimental system includes a pressure device plunger pump 1, a plugging fluid container 3, a pressure gauge, and a hydraulic pump 8. The plunger pump 1 passes through the plugging fluid container 3 and the high-fidelity leaky layer. Simulator 5 is connected. A pressure gauge 2 is installed between the plunger pump 1 and the leakage fluid container 3, a pressure gauge 4 is installed between the leakage fluid container 3 and the high-fidelity leakage layer simulator 5, and a pressure gauge 4 is installed between the annular space 15 and the hydraulic pump 9. There are pressure gauges7. Piston pump 1 The maximum displacement of the pump is 13L / h, and the maximum pressure is 50Mpa. The plunger pump hydraulically injects the plugging into the simulated formation. The working medium used is clear water, preferably distilled water. The leak st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com