Electric adjusting apparatus of tool holder

A technology for adjusting devices and knife holders, which is applied in printing, rotary printing machines, printing machines, etc., can solve problems such as low work efficiency and inaccurate position adjustment, and achieve the effect of improving work efficiency and ensuring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

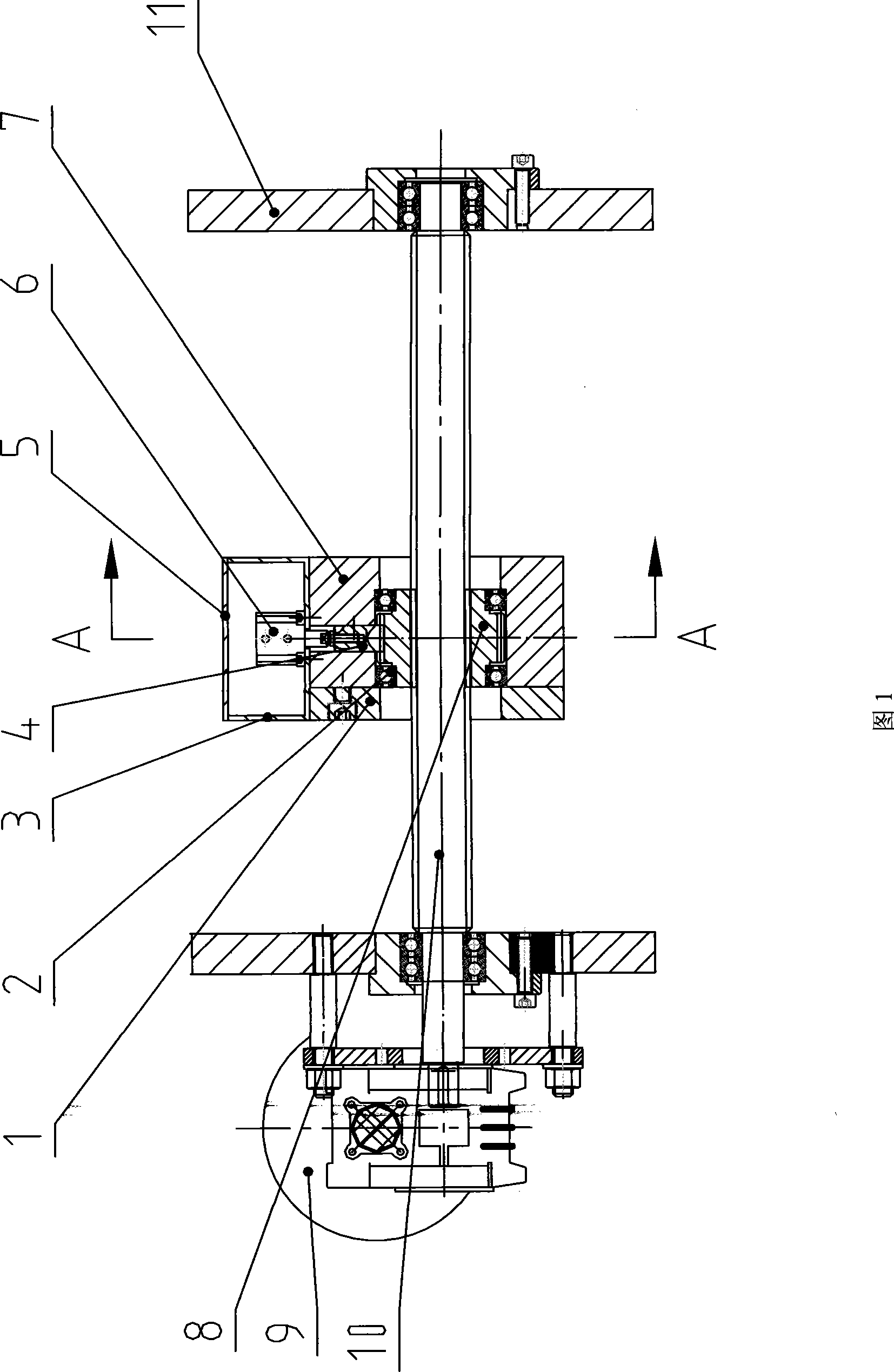

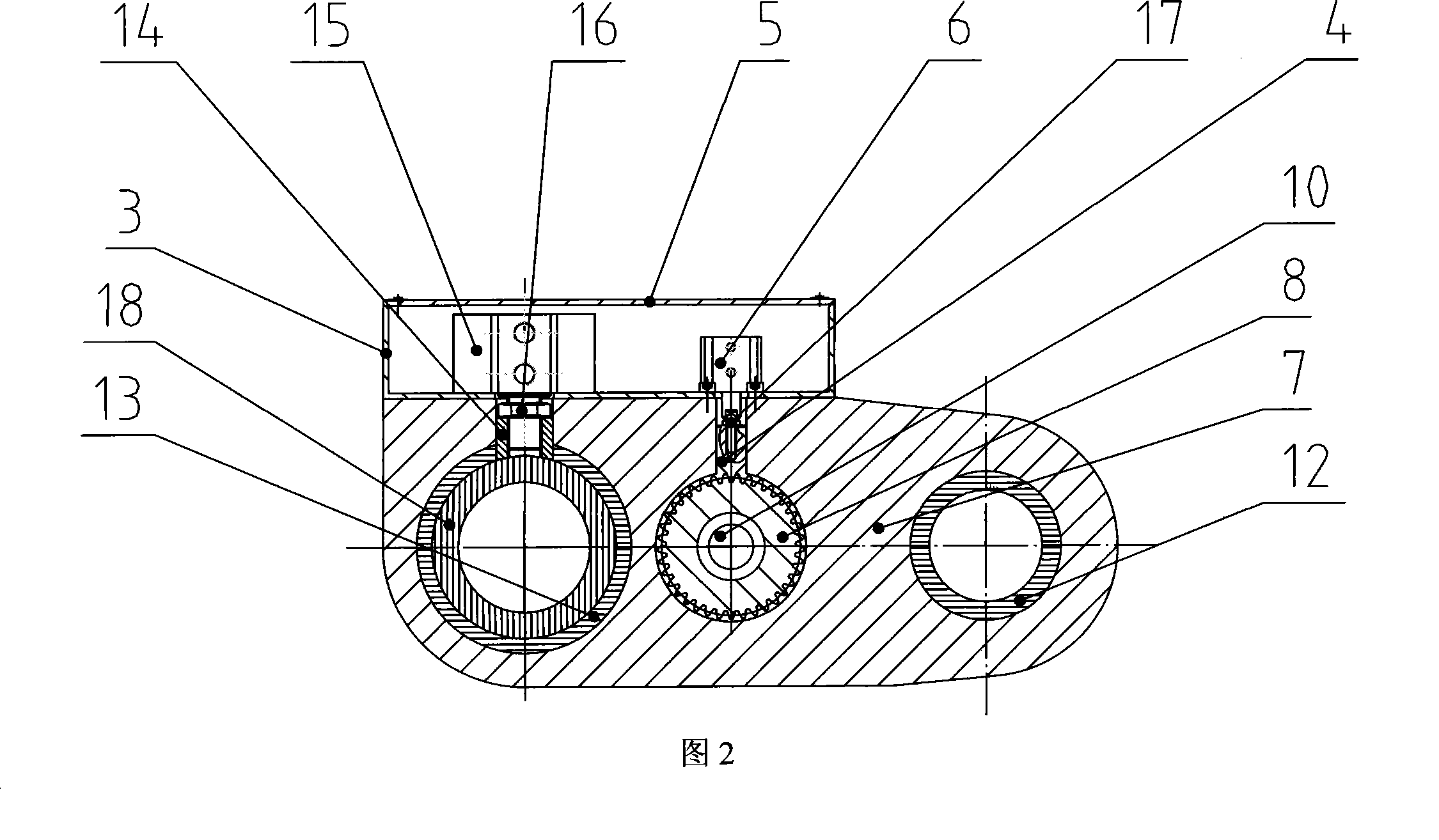

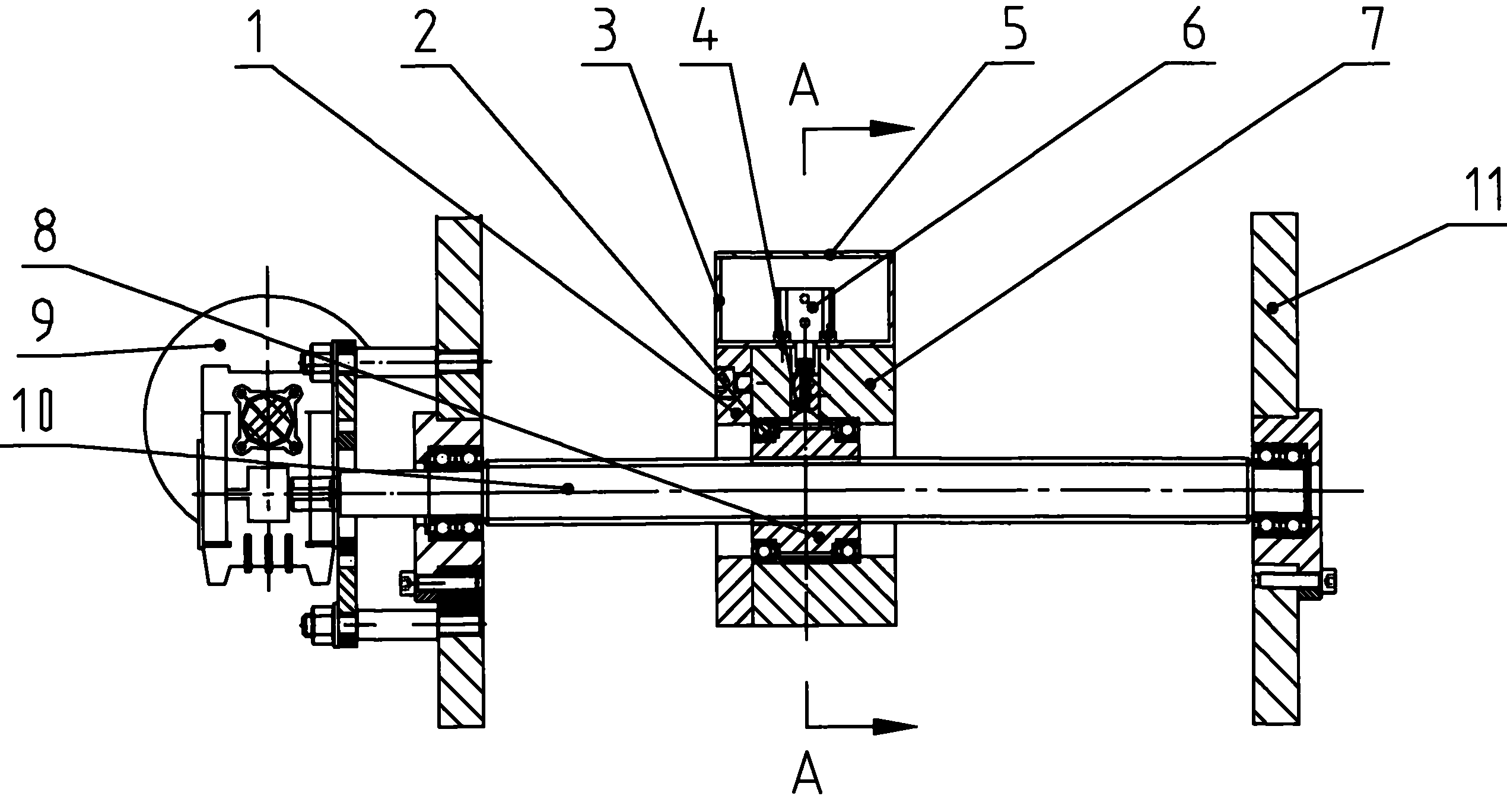

[0013] like figure 1 and figure 2 The specific embodiment of the present invention shown is a kind of tool post electric adjustment device, which includes wallboards 11 at both ends, a lead screw 10 installed between the wallboards 11, and a lead screw 10 installed on the outside of one end wallboard. Linked reducer 9, lead screw 10 is provided with a knife rest 7, inside the said knife rest 7 is provided with a gear 8 set on the lead screw 10, between the knife rest 7 and gear 8 is provided with a rolling bearing 2, the The outer edge of the gear 8 is provided with meshing teeth. The top of knife rest 7 is provided with cylinder 6, and the bottom of cylinder 6 utilizes nut 17 to be connected with a stop shaft 4, and stop shaft 4 is positioned at gear 8 directly above. A first guide shaft 18 and a second guide shaft 12 are also arranged between the wallboards 11 at the two ends, and a matching guide shaft hole is provided inside the knife rest 7; the periphery of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com