Creel

A technology of creel and bobbin, used in textile and papermaking, weft knitting, knitting, etc., can solve the problems of low yarn threading efficiency, many types of creel, and inability to expand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

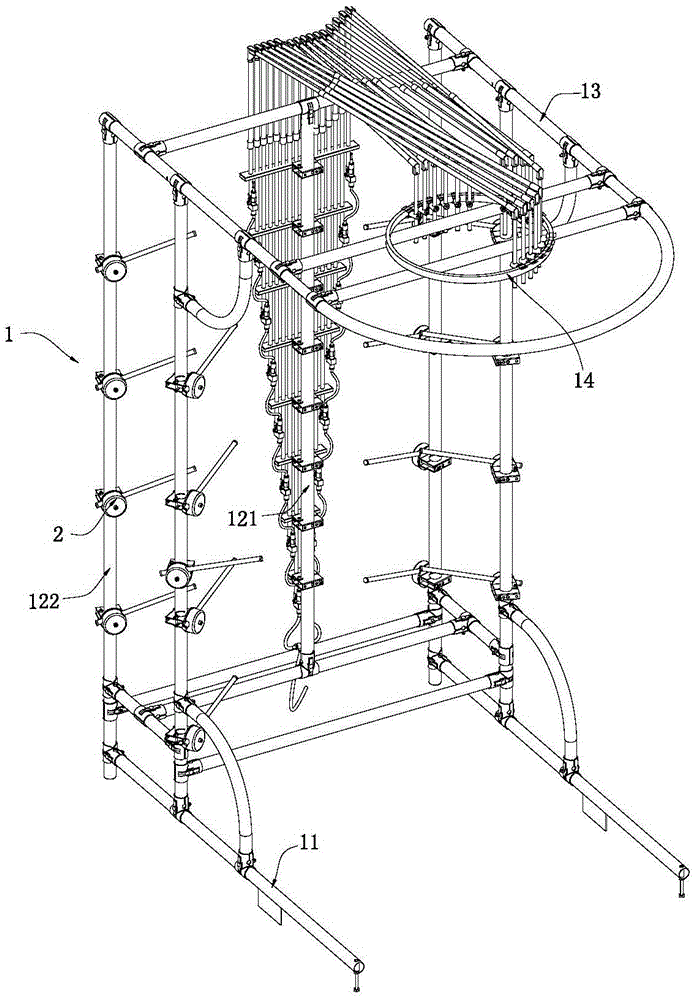

[0021] Such as Figure 1~Figure 5 A yarn creel shown includes a creel body 1 , several bobbin support devices 2 and several yarn threading channels arranged on the creel body 1 . The creel body 1 includes a bottom frame 11 , side frames arranged on the bottom frame 11 , a top frame 13 arranged on the side frames, and a yarn output tray 14 on the top frame 13 . The side frame includes a first side bar 121 and a plurality of second side bars 122 on both sides of the first side bar 121 .

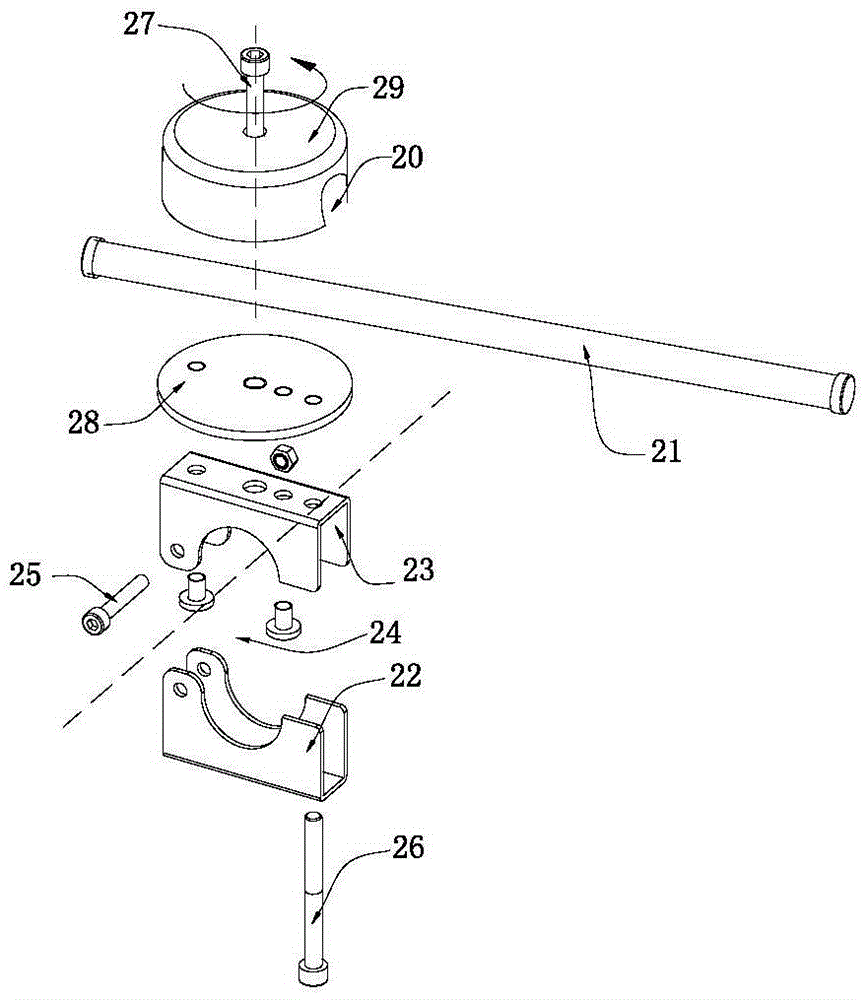

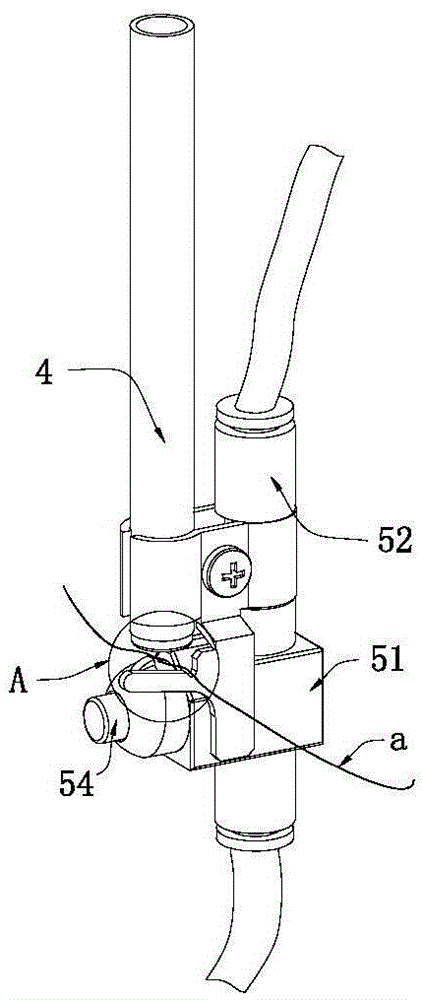

[0022] The bobbin supporting device 2 is arranged on the second side bar 122, and the bobbin supporting device 2 includes a base for positioning on the creel, a support positioned on the base, and a support positioned on the support. Yarn bobbin bar 21. The base includes a first loop 22 and a second loop 23 oppositely arranged, and a shaft hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com