Method for positioning and mounting large-scale bridge support

A technology of bridge bearing and installation method, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of high positioning accuracy, affecting the overall force, and difficulty in gas discharge, so as to improve the overall force resistance and facilitate adjustment. Reliable, easy-to-follow results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] The invention provides a method for positioning and installing a large bridge support, the specific steps of which are as follows:

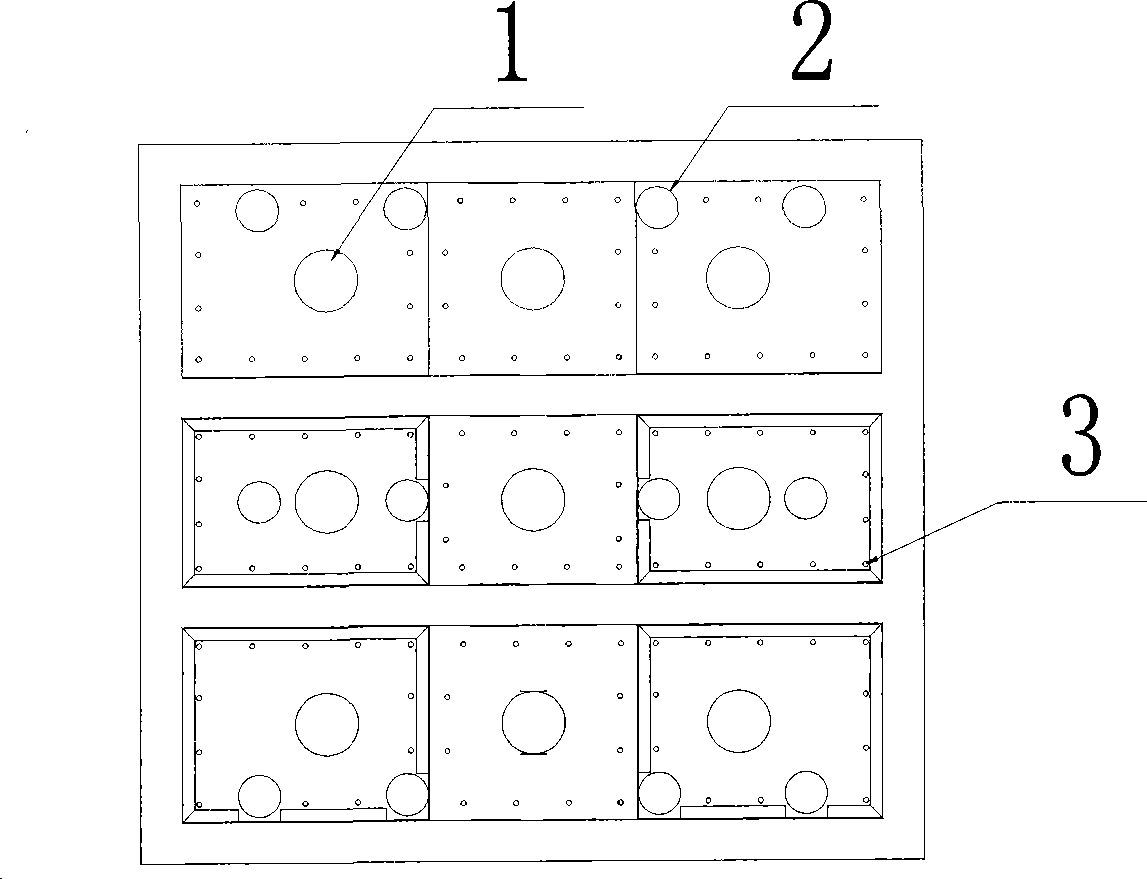

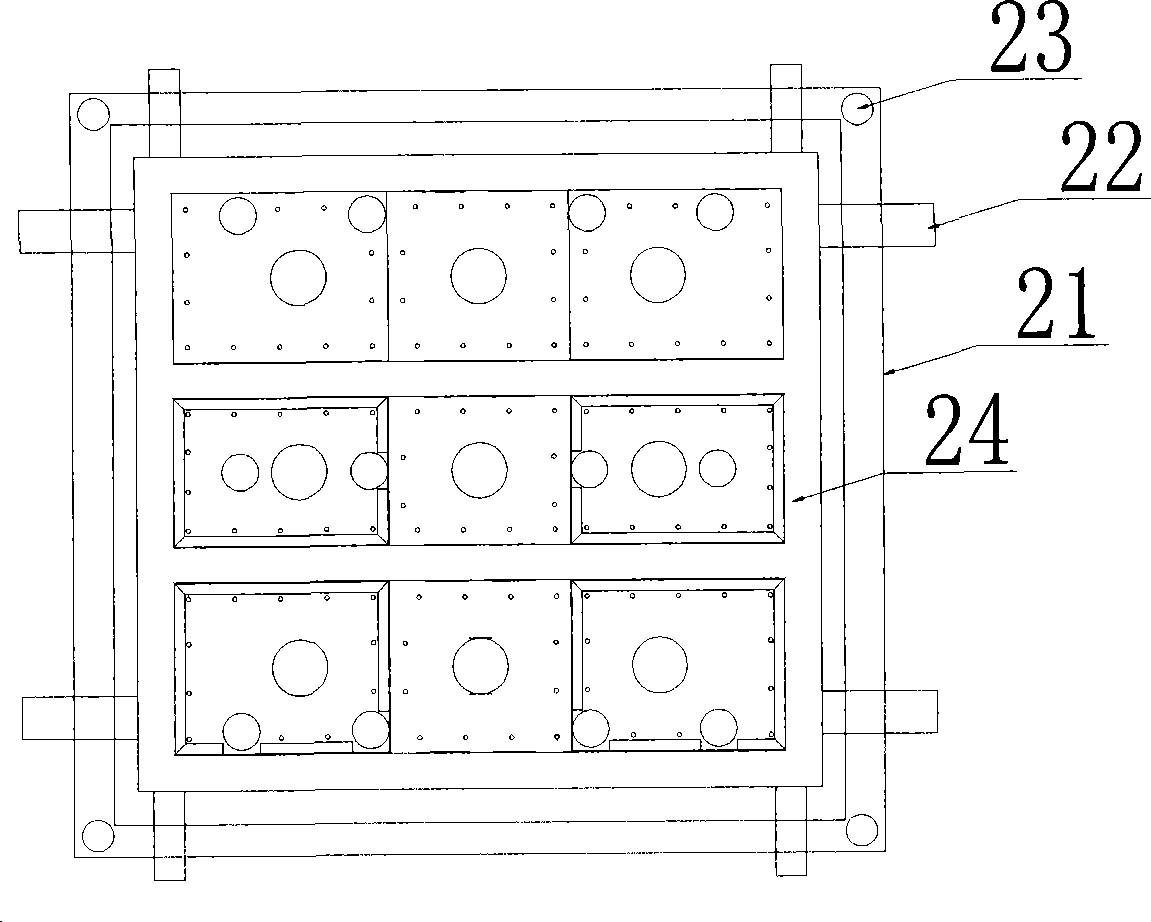

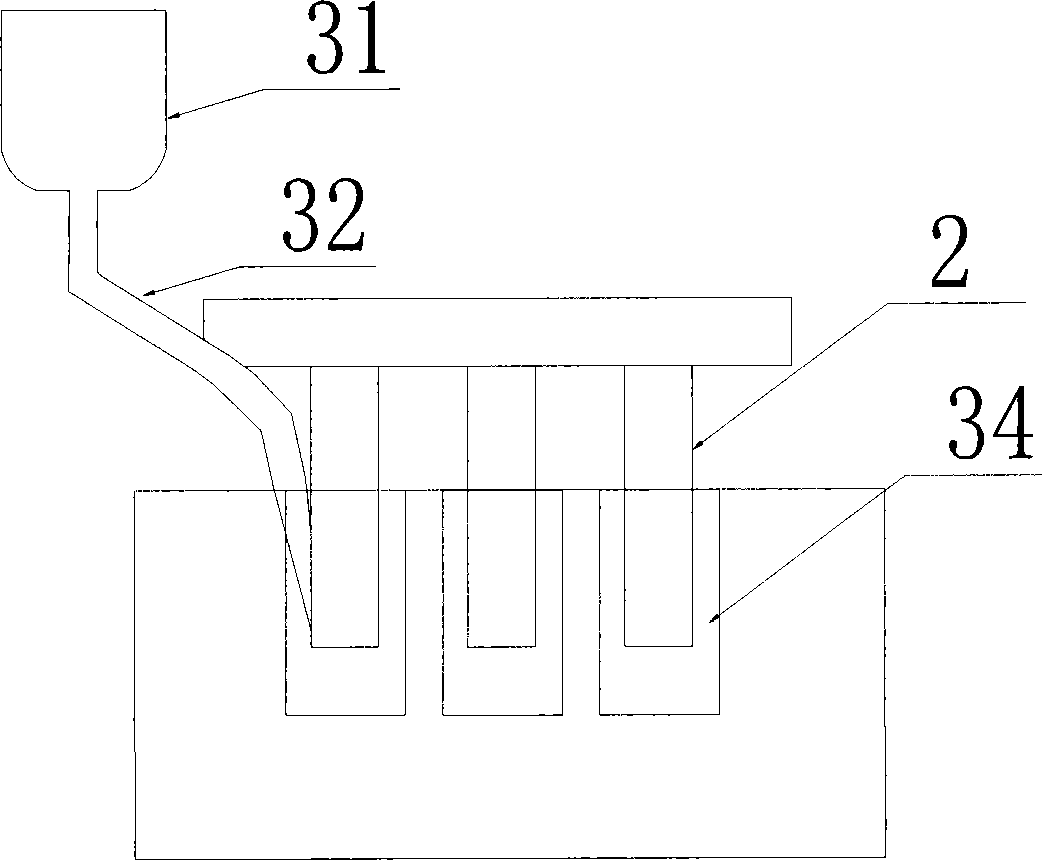

[0023] Step 1, making steel seat plate (see figure 1 ): The said steel seat plate is divided into 9 independent closed area structures according to 3×3, and a Φ300mm blanking hole 1 is reserved in the middle of the top surface of each independent closed area, and the surrounding area of each independent closed area is 5cm away from the edge. A number of air outlets 3 are arranged, the size of the air outlets 3 is adapted to the particle size of the coarse aggregate in the concrete, so as to ensure that the air outlets 3 will not be blocked during concrete pouring, and a number of anchor bolts 2 are also arranged on each independent closed area;

[0024] Step 2. Accurately locate the steel seat plate of the support (see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com