Magnesium alloy large continuous melting system

A magnesium alloy and smelting furnace technology, applied in the field of large-scale continuous smelting systems, to achieve the effects of improving metallurgical quality, improving working environment, and increasing smelting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

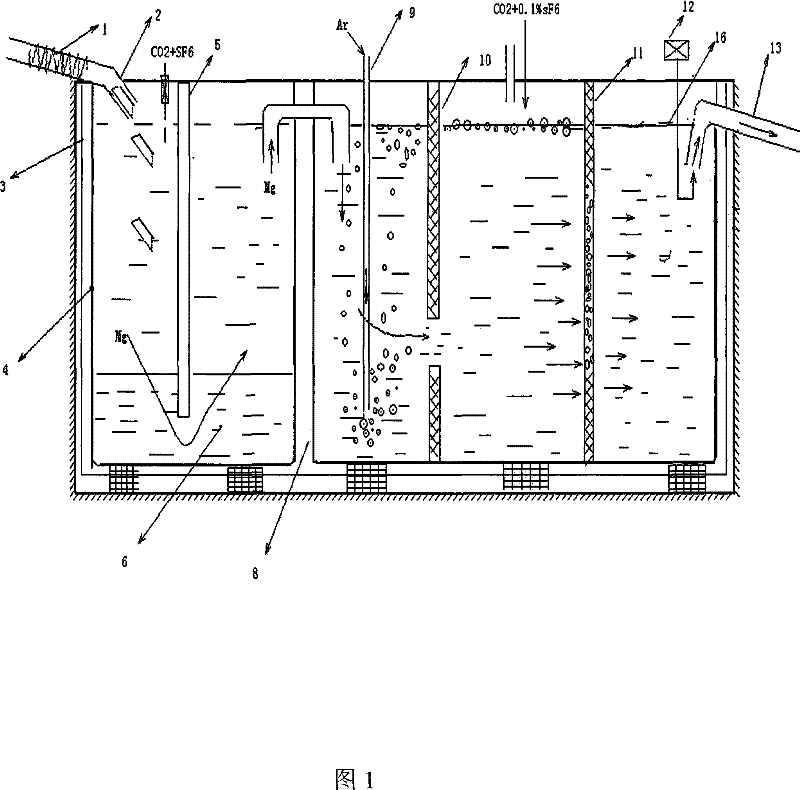

[0031] The large-scale continuous smelting system with an annual production capacity of 10,000 tons of magnesium alloy liquid is calculated as 60% of the annual smelting time utilization rate, and the smelting rate is 2 tons per hour. Design a large continuous melting system based on 2 tons per hour.

[0032] Since the magnesium alloy is heated at 480°C for a long time in the atmosphere, the oxidation is not obvious, and the temperature is even allowed to be higher during rapid heating. The preheating furnace needs to rapidly and uniformly heat 2 tons of magnesium alloy ingots from room temperature to close to 500°C. At the same time, the temperature must be uniform inside and outside. When the frequency of induction heating is low, the skin effect is low and the thermal conductivity of magnesium is good. Frequency induction heating. Calculated from the heat capacity of magnesium. Considering factors such as theoretical output power and thermal efficiency, the output power o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com