Laser peeling and lamination integration device

A laser peeling and film sticking technology, which is applied in the directions of lamination devices, chemical instruments and methods, lamination auxiliary operations, etc. The effect of improving capacity utilization, reducing manufacturing costs and saving factory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

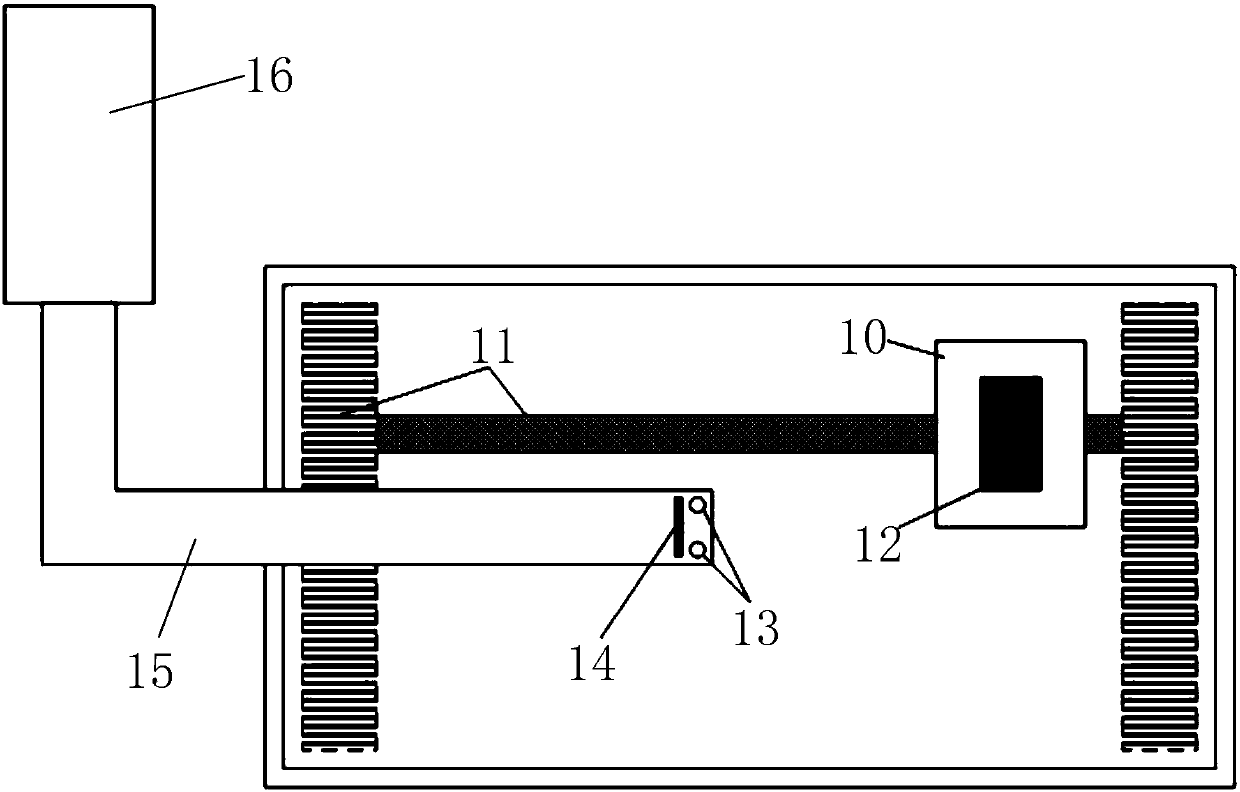

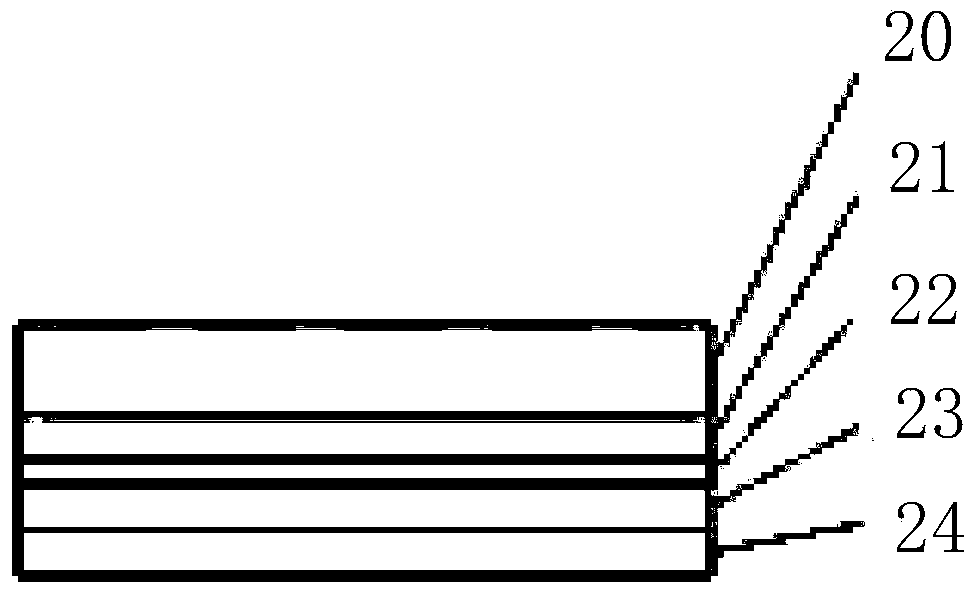

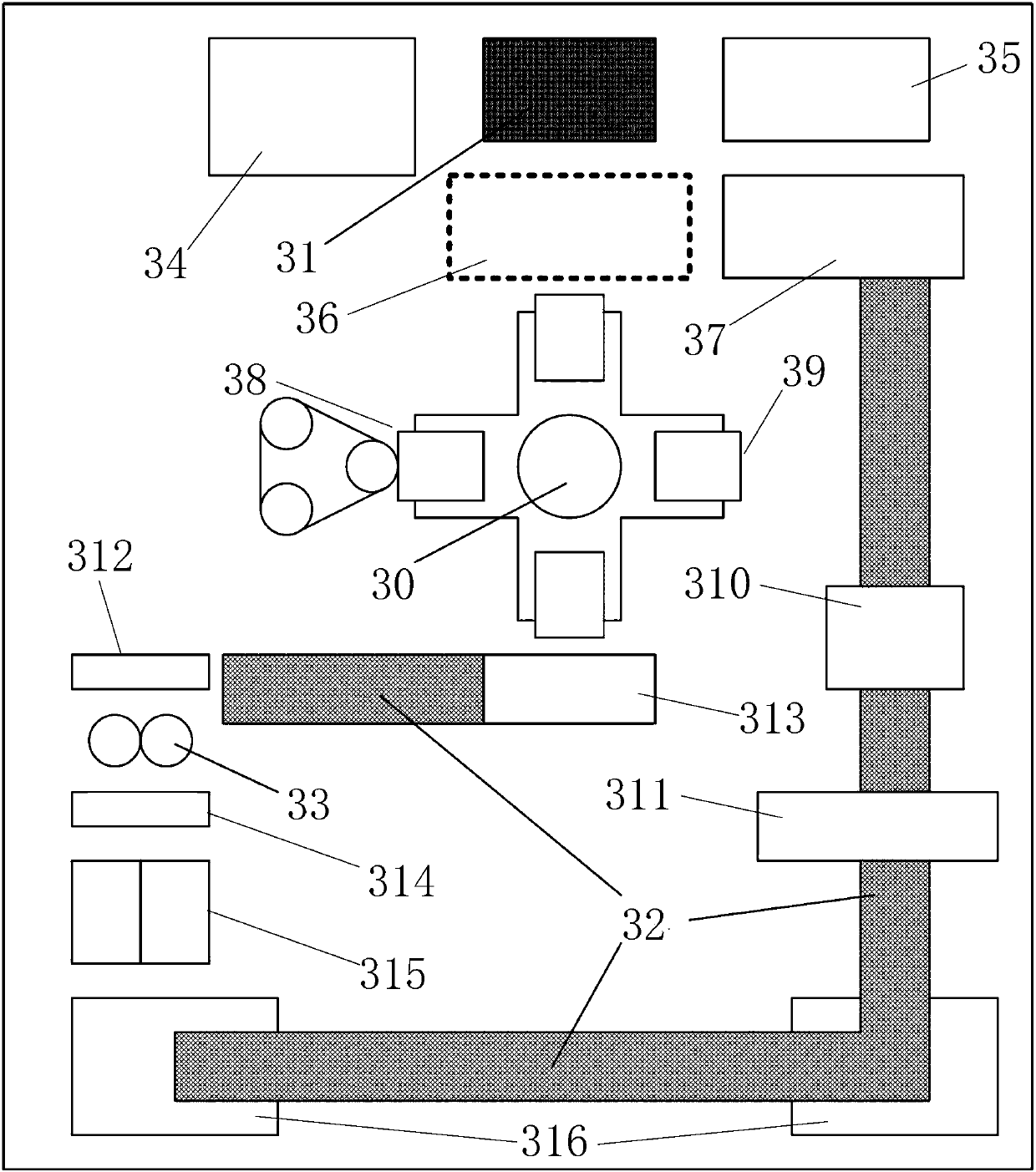

[0047] The following will combine Figure 1 to Figure 10 The laser peeling and film sticking integrated device provided by the present invention is described in detail, which is an optional embodiment of the present invention. It can be considered that those skilled in the art can modify and modify it within the scope of not changing the spirit and content of the present invention. polish.

[0048] Please refer to Figure 4 , and in conjunction with other drawings, the present invention provides a laser peeling and film sticking integrated device, including:

[0049] Two laser peeling workpiece tables 407 of mirror image setting, please refer to Figure 5 , for receiving the hard screen to be peeled off from the feeding station and transporting the hard screen to be peeled off 403 to the stripping station in turn, and transporting the peeled hard screen to the handover station in turn;

[0050] To understand laser lift off, please also refer to figure 1, which is a laser s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com