Production technology of anti-ageing plastic woven bag

A technology of plastic woven bag and production process, applied in the field of production process of anti-aging plastic woven bag, can solve the problem of loss of transparency, easy aging and degradation of polypropylene material, loss of tensile strength, impact strength and bending strength of woven bag and other problems, to achieve the effect of inhibiting thermo-oxidative aging degradation, improving antioxidant efficiency, and improving color stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

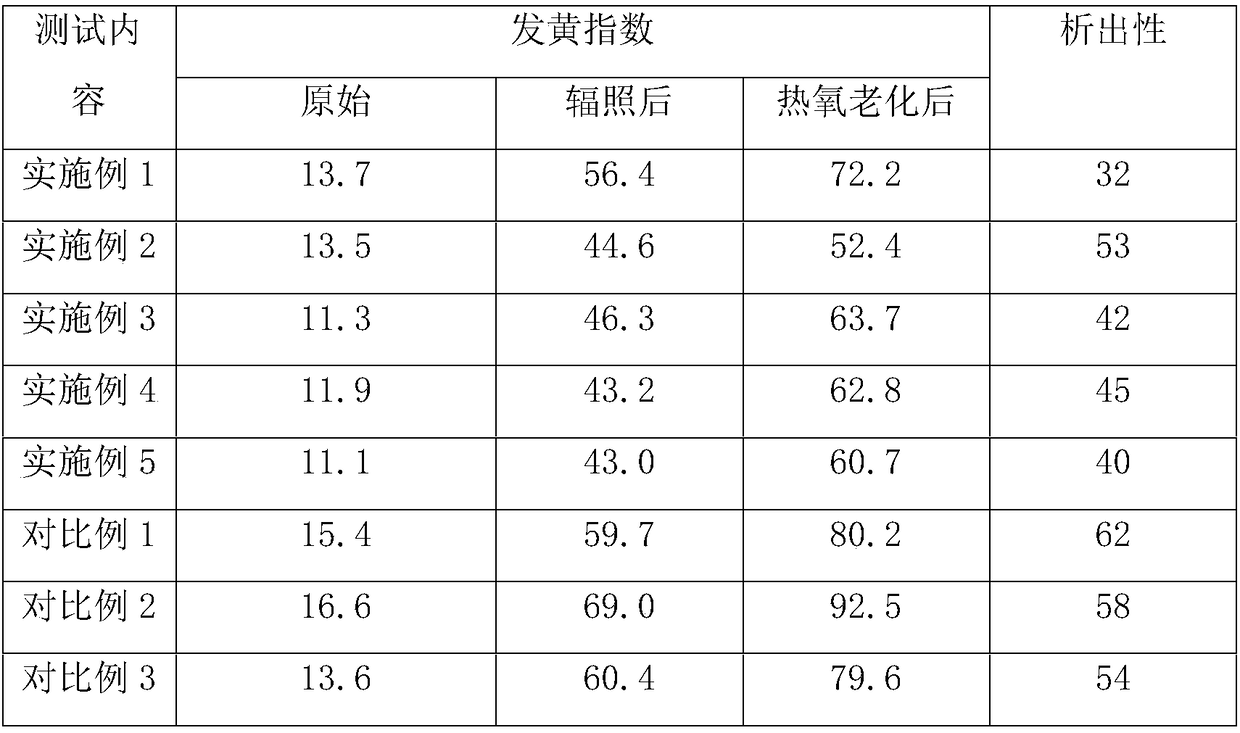

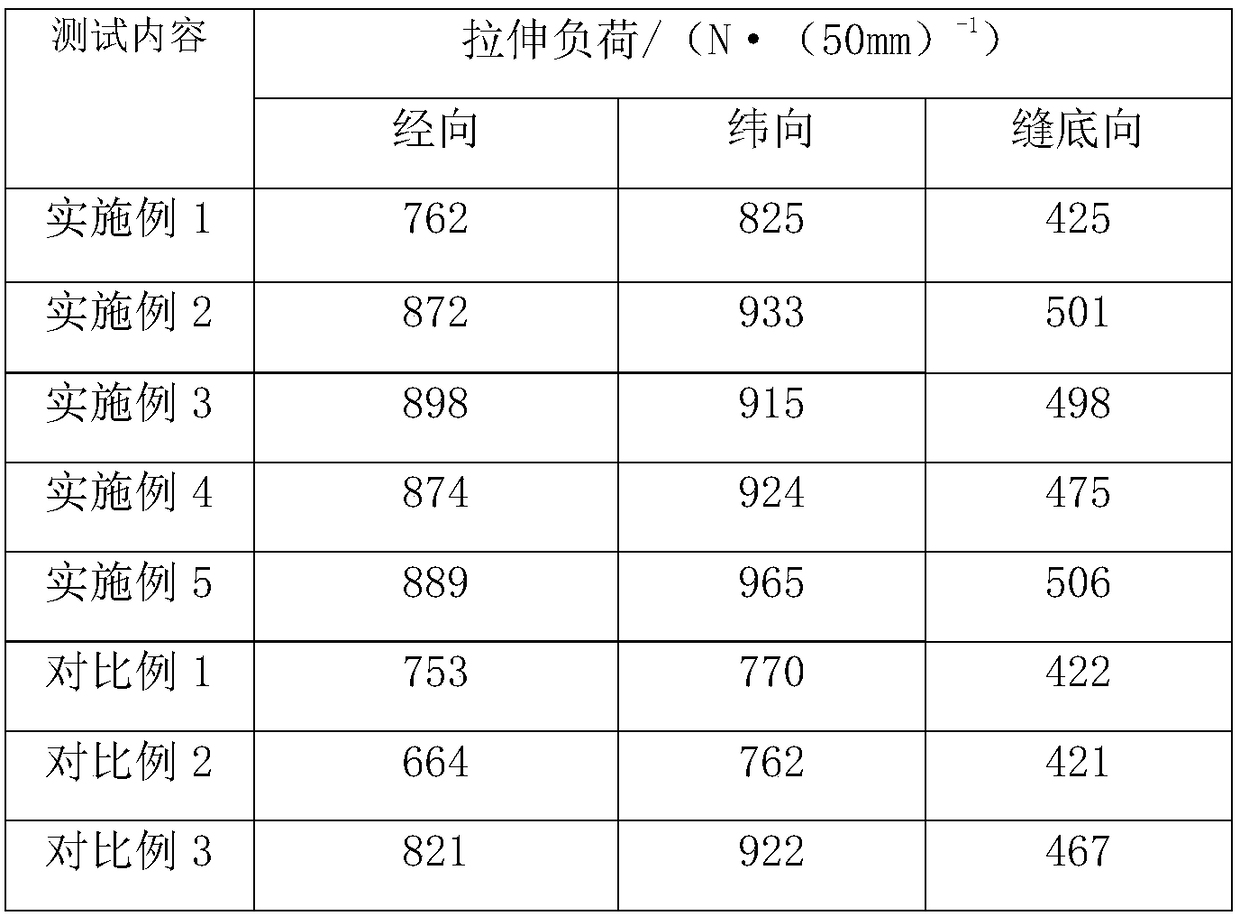

Examples

Embodiment 1

[0026] A production process of an anti-aging plastic woven bag, comprising the following steps:

[0027] S1: Raw material blending and drying: first add 100g of hindered amine light stabilizer aqueous solution to 10kg of filler masterbatch powder, stir and dry to prepare treated filler masterbatch, mix 100kg of polypropylene granules, 20g of cis-1 , 2-stilbene, 10g bis-octylamine, 5g aromatic phosphite, 0.02g hydroquinone, treated filler masterbatch, 100g2,2'-methylene-bis(4,6-di-tert-butyl Base phenyl) hydroxysodium phosphate is put into the drying mixer and stirred, put into the drying mixer and stirred, the drying temperature is 80-100 ℃, and the drying time is 30-50 minutes;

[0028] S2: wire drawing process: after the blending and drying of step S1, the material enters the extruder, is heated by the barrel and sheared by the screw and the barrel, and is extruded into a film through a die. The heating temperature is 175°C , and then cooled by water at 30°C, cut into embry...

Embodiment 2

[0034] A kind of production technology of anti-aging plastic woven bag, it is characterized in that: comprise the following steps:

[0035] S1: Raw material blending and drying: first add 500g of hindered amine light stabilizer to form an aqueous solution into 15kg of filler masterbatch powder, stir and dry to prepare a treated filler masterbatch, mix 100kg of polypropylene particles, 50g of cis-1 ,2-stilbene, 30g bis-octylamine, 10g aromatic phosphite, 0.05g hydroquinone, treated filler masterbatch, 200g2,2'-methylene-bis(4,6-di-tert-butyl Base phenyl) hydroxyaluminum phosphate is put into the drying mixer and stirred, the drying temperature is 80-100 ℃, and the drying time is 30-50 minutes;

[0036] S2: wire drawing process: after the blending and drying of step S1, the material enters the extruder, is heated by the barrel and sheared by the screw and the barrel, and is formed and extruded into a film by the die head. The heating temperature is 185°C , and then cooled by wa...

Embodiment 3

[0042] A production process of an anti-aging plastic woven bag, comprising the following steps:

[0043]S1: Raw material blending and drying: first add 250g of hindered amine light stabilizer to form an aqueous solution into 12.5kg of filler masterbatch powder, stir and dry to prepare a treated filler masterbatch, mix 100kg of polypropylene granules, 30g of cis Put 1,2-stilbene, 20g bis-octylamine, 7g aromatic phosphite, 0.03g hydroquinone, treated filler masterbatch, and 100g di-(p-methylbenzylidene)sorbitol into the dry mixer Stir, the drying temperature is 80-100°C, and the drying time is 30-50 minutes;

[0044] S2: wire drawing process: after the blending and drying of step S1, the material enters the extruder, is heated by the barrel and sheared by the screw and the barrel, and is extruded into a film through a die. The heating temperature is 180°C , and then cooled by water at 35°C, cut into embryo silk with a blade, and stretched through a drying plate to form a flat f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com