Cable clip rotary type anti-bouncing spacer

A rotary, anti-galling technology, which is applied in the direction of the device for maintaining the distance between parallel conductors and the suspension device of the cable, etc., can solve the problems of inability to reduce the torque effect of the conductor, and cannot change the shape of the ice or snow, so as to reduce galloping The effect of reducing the amplitude, reducing tension fluctuations, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

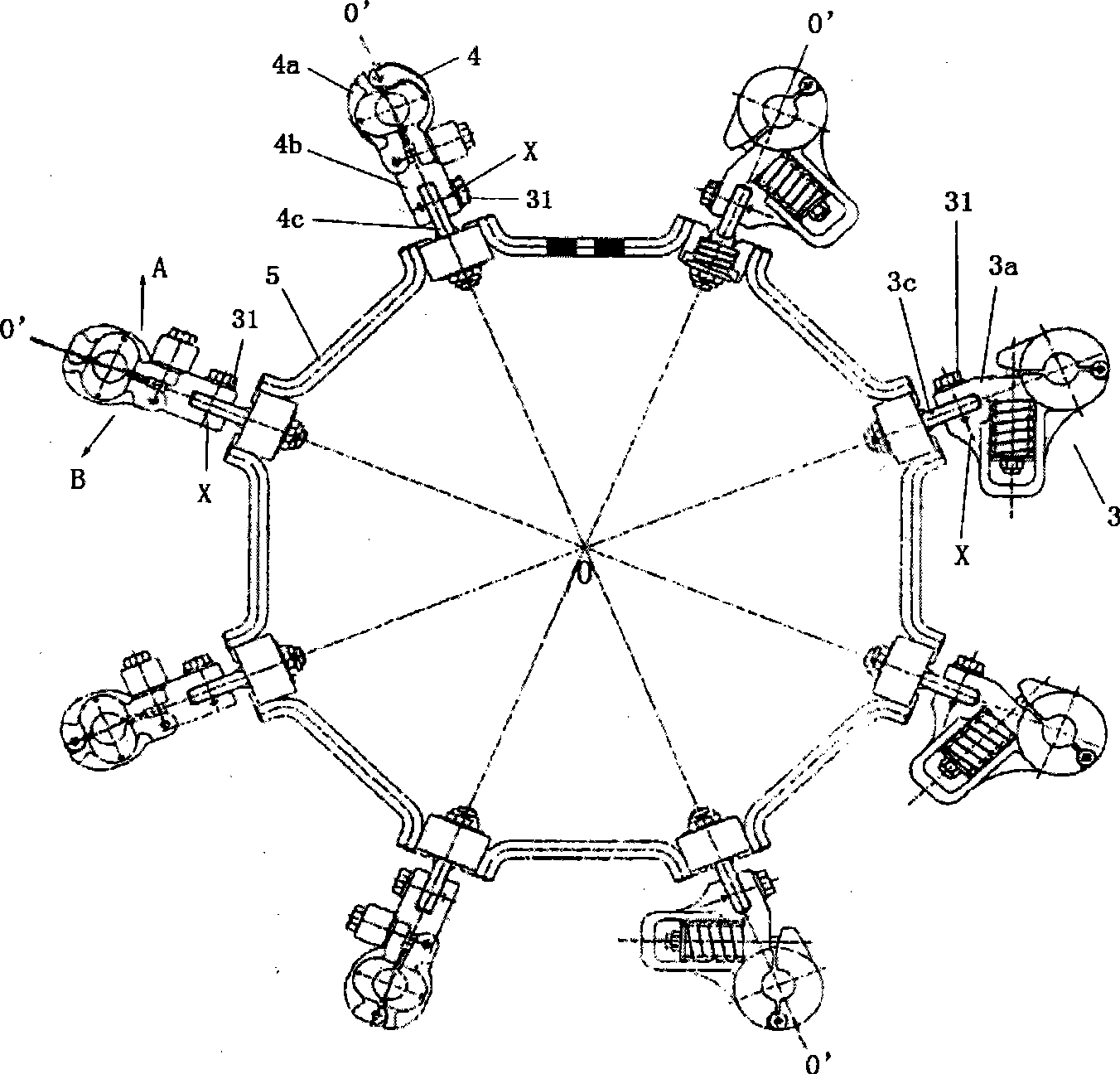

[0036] figure 2 It is a front view of the eight-split wire protection spacer 1 with four fixed clamps 3 and four rotary clamps 4 of the present invention. In this figure, four fixed wire clamps 3 and four rotary wire clamps 4 are continuously installed on one side of the wire clamp bracket 5 .

[0037] exist figure 2 Among them, the spacer bar 1 of the present invention has eight wire clips and a regular polygon (corresponding to the number of wire clips, octagonal in this embodiment) wire clip bracket 5, and the wire clips are installed at equal intervals. on bracket 5. The wire clamps include a fixed type wire clamp 3 and a rotary type wire clamp 4 .

[0038] In this example, if figure 2 As shown, the quantity of the fixed line clamps 3 is equal to the quantity of the rotary line clamps 4, each accounting for half of the entire line clamps.

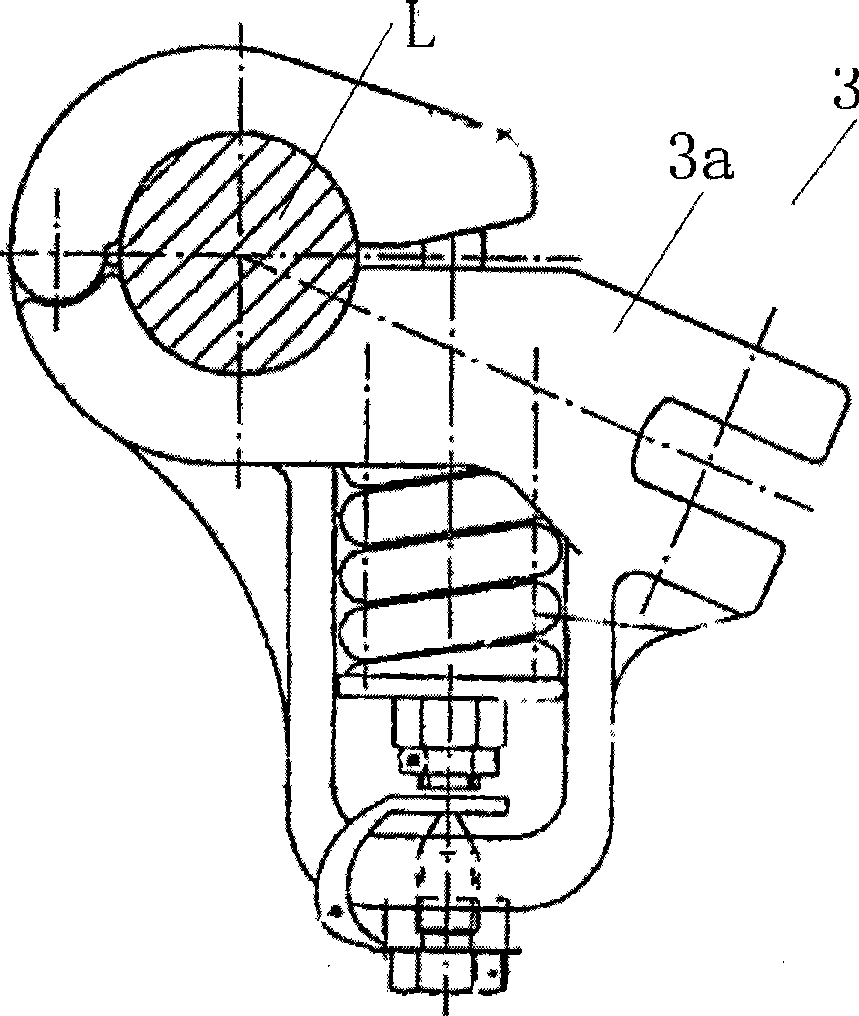

[0039] As shown in the figure, the rotary clamp 4 mainly includes a clamp head 4a, a clamp slider 4b and a support rod 4c. Th...

Embodiment 2

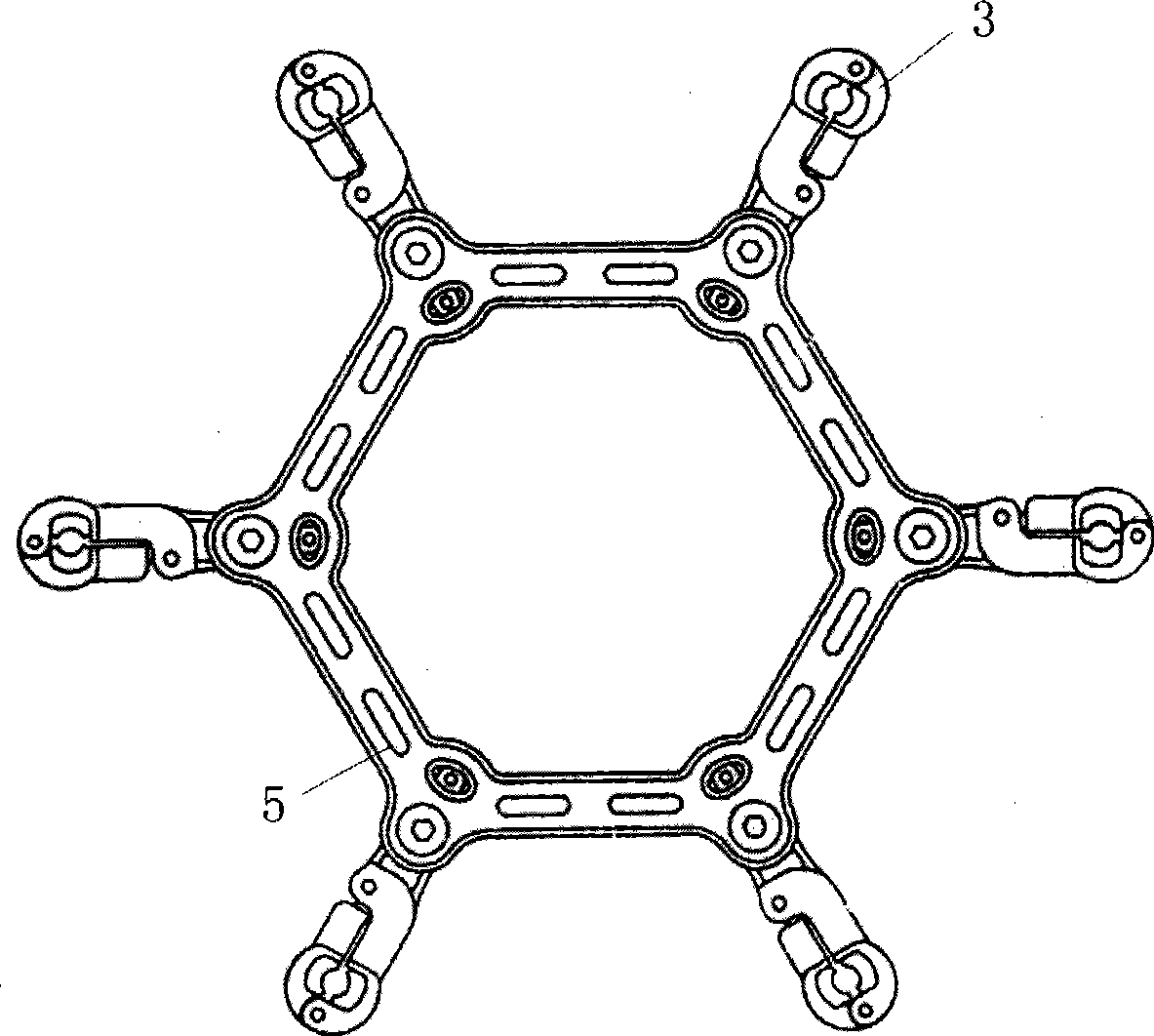

[0057] In Embodiment 1, except that 6 wire clips are installed on the wire clip rotary anti-flapping spacer, in which there are three fixed wire clips 3 and three rotary wire clips 4, the others are the same as in Embodiment 1, The clamp rotary anti-galling spacer of the present invention is obtained.

Embodiment 3

[0059] In embodiment 1, except that four wire clips are installed on the wire clip rotary anti-flapping spacer, in which there are two fixed wire clips 3 and two rotary wire clips 4, the others are the same as embodiment 1, The clamp rotary anti-galling spacer of the present invention is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com