Intelligent constant-tension yarn feeding method for knitting machine

A knitting machine, constant tension technology, applied in the directions of knitting, weft knitting, warp knitting, etc., can solve the problem of difficulty in reducing the variation of yarn tension, and achieve the effect of reducing the variation of yarn tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

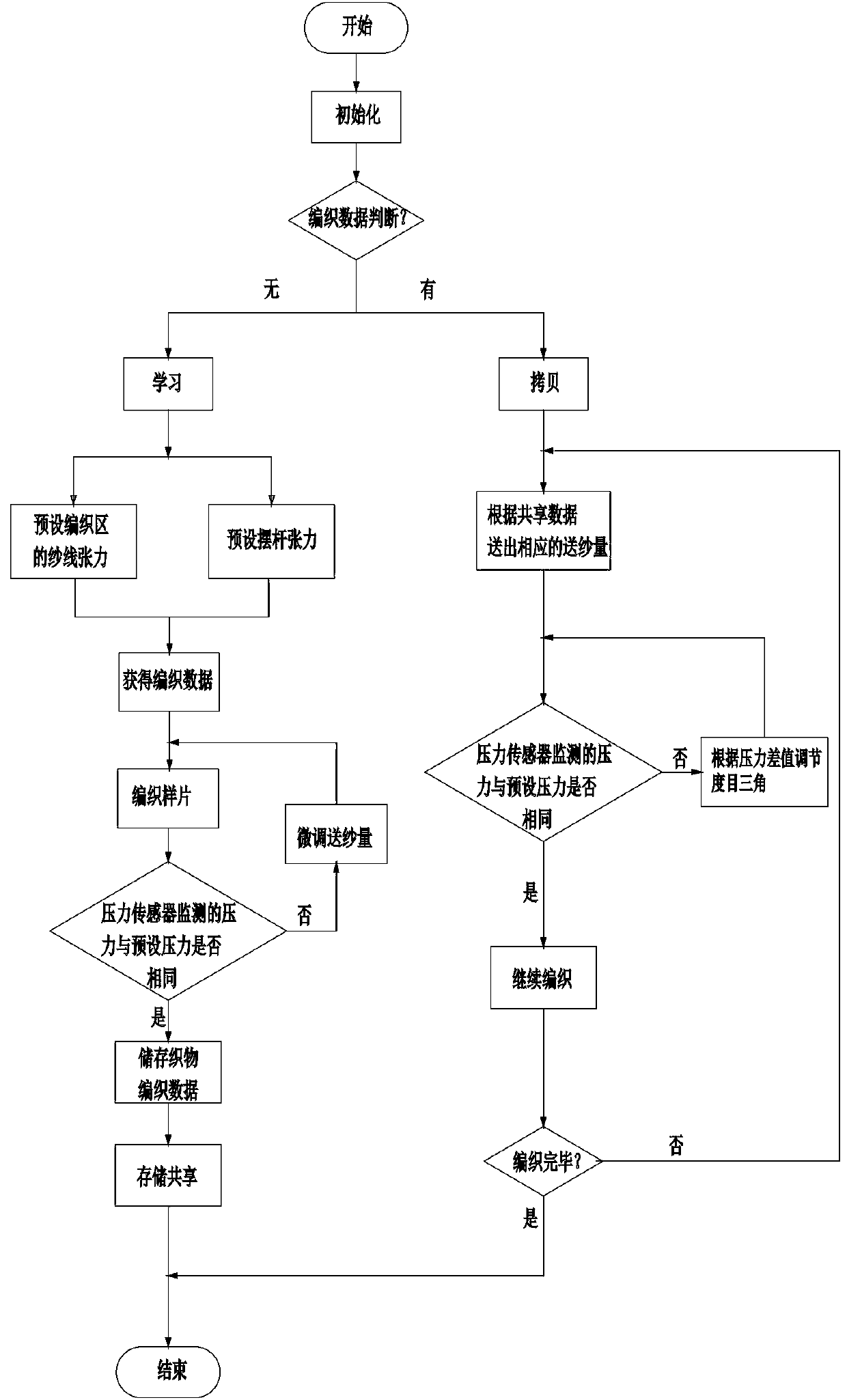

Method used

Image

Examples

Embodiment 1

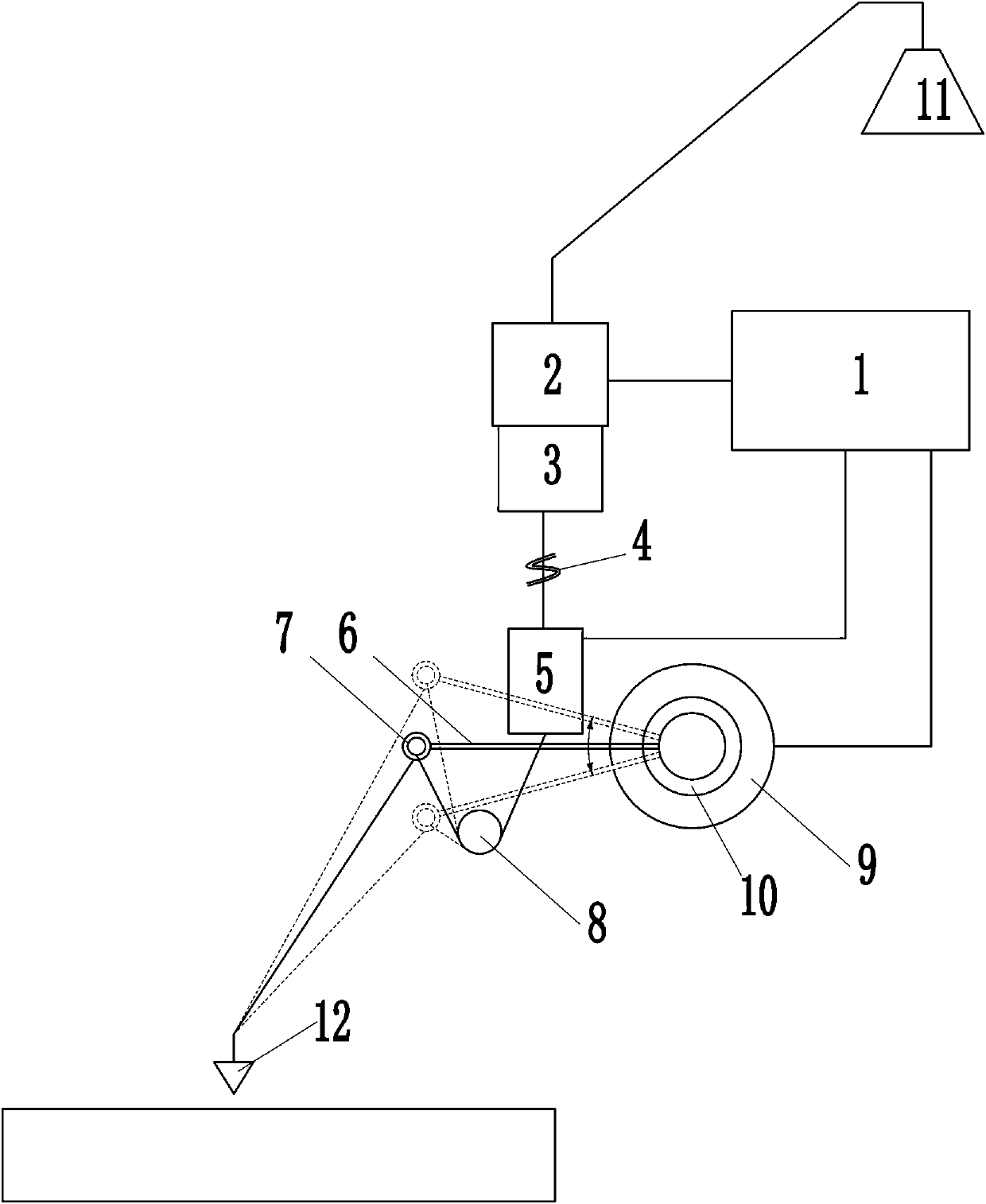

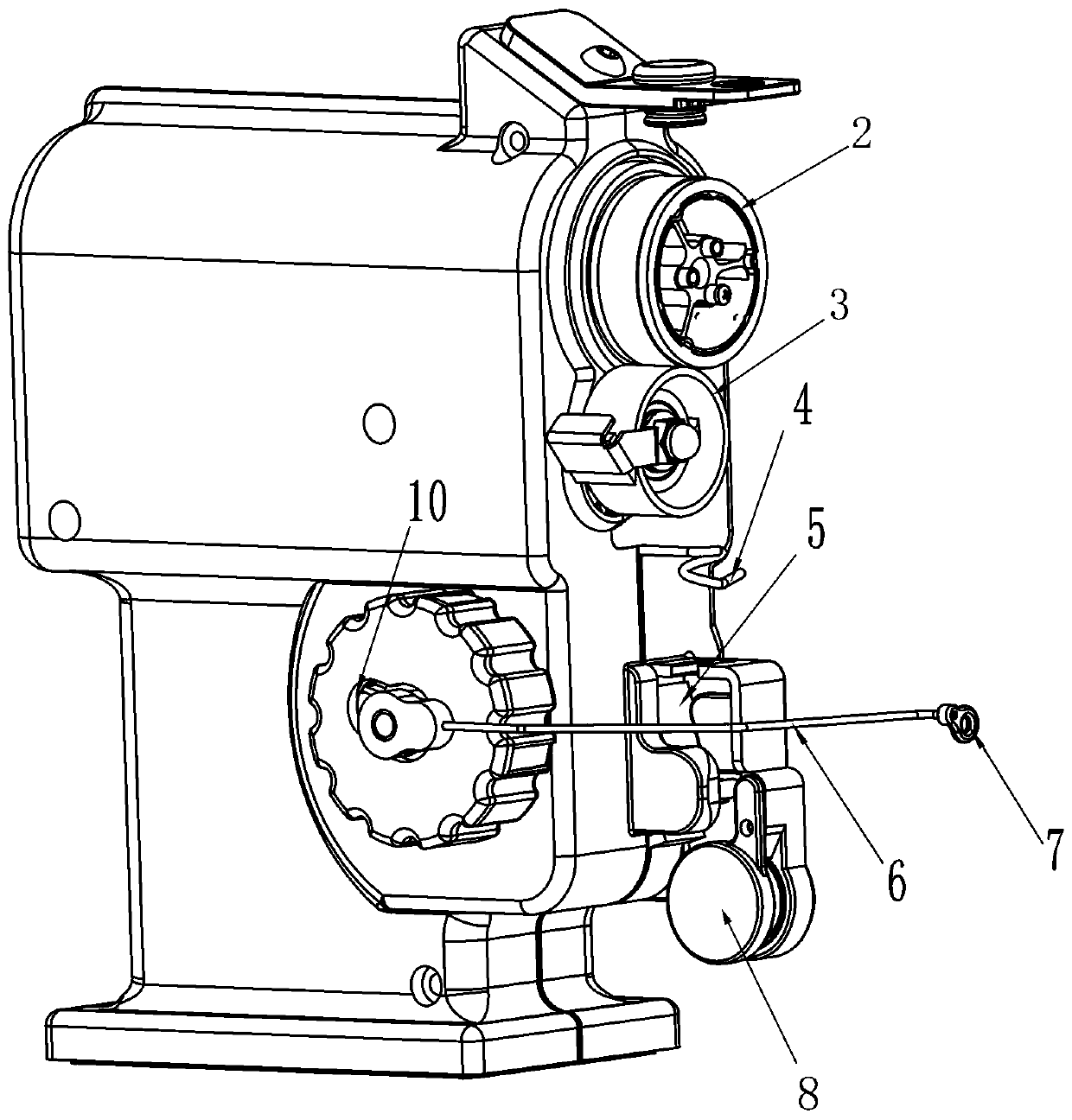

[0026] This embodiment includes a yarn feeding motor 1, the yarn feeding motor drives the driving wheel 2, and the driving wheel and the driven wheel 3 cooperate to extract the yarn from the yarn bobbin 11; it also includes a swing rod 6, and the end of the swing rod is provided with a spring 10 With the angle sensor 9, the spring 10 is used to manually adjust the tension value of the swing rod, and the angle sensor 9 is used to measure the deflection angle of the swing rod. The yarn is sent out from the yarn feeding motor, passes through a pressure sensor 5, then passes through the yarn wheel 8 and the ceramic ring 7 at the end of the pendulum in turn, and finally the yarn is fed by the yarn guide nozzle 12.

[0027] The swing rod 6 can be manually adjusted to a suitable position matching the preset tension value, and the force equal to the preset tension value is applied to the front end of the swing rod, which is opposite to the direction of the adjustable torsion force give...

Embodiment 2

[0033] This embodiment includes a yarn feeding motor 1, the yarn feeding motor drives the driving wheel 2, and the driving wheel and the driven wheel 3 cooperate to extract the yarn from the yarn bobbin 11; it also includes a swing rod 6, and the end of the swing rod is provided with a torque The generator 14, the torque controller 13 and the angle sensor 9, the torque generator 14 applies a variable torque to the swing rod, and the angle sensor 9 is used to measure the deflection angle of the swing rod. The yarn is sent out from the yarn feeding motor, passes through a pressure sensor 5, then passes through the yarn wheel 8 and the ceramic ring 7 at the end of the pendulum in turn, and finally the yarn is fed by the yarn guide nozzle 12.

[0034] The swing rod 6 can be electrically adjusted to a suitable position matching the preset tension value, and the force equal to the preset tension value is applied to the front end of the swing rod, which is opposite to the direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com