Mould with waste material slide-out component

A scrap and component technology, applied in the field of molds with scrap slip-out parts, can solve problems such as mold design limitations, scrap removal difficulties, and production line stoppages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

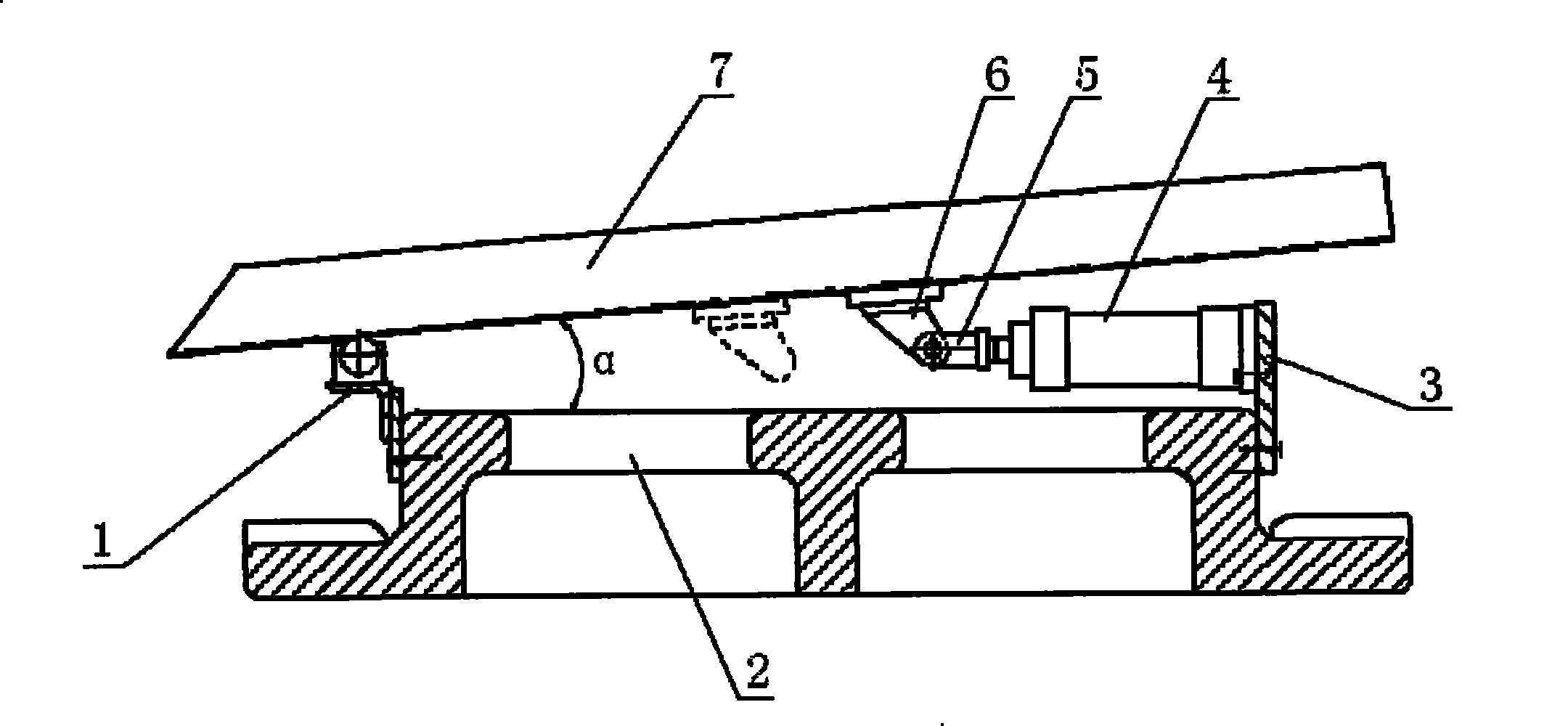

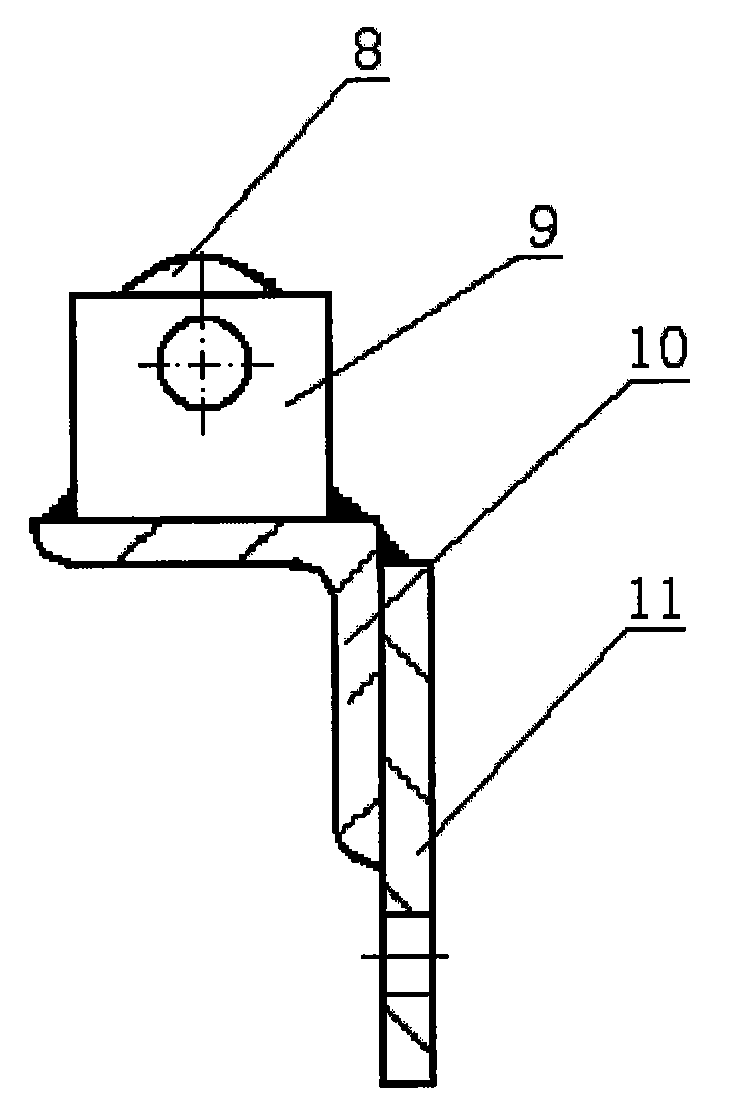

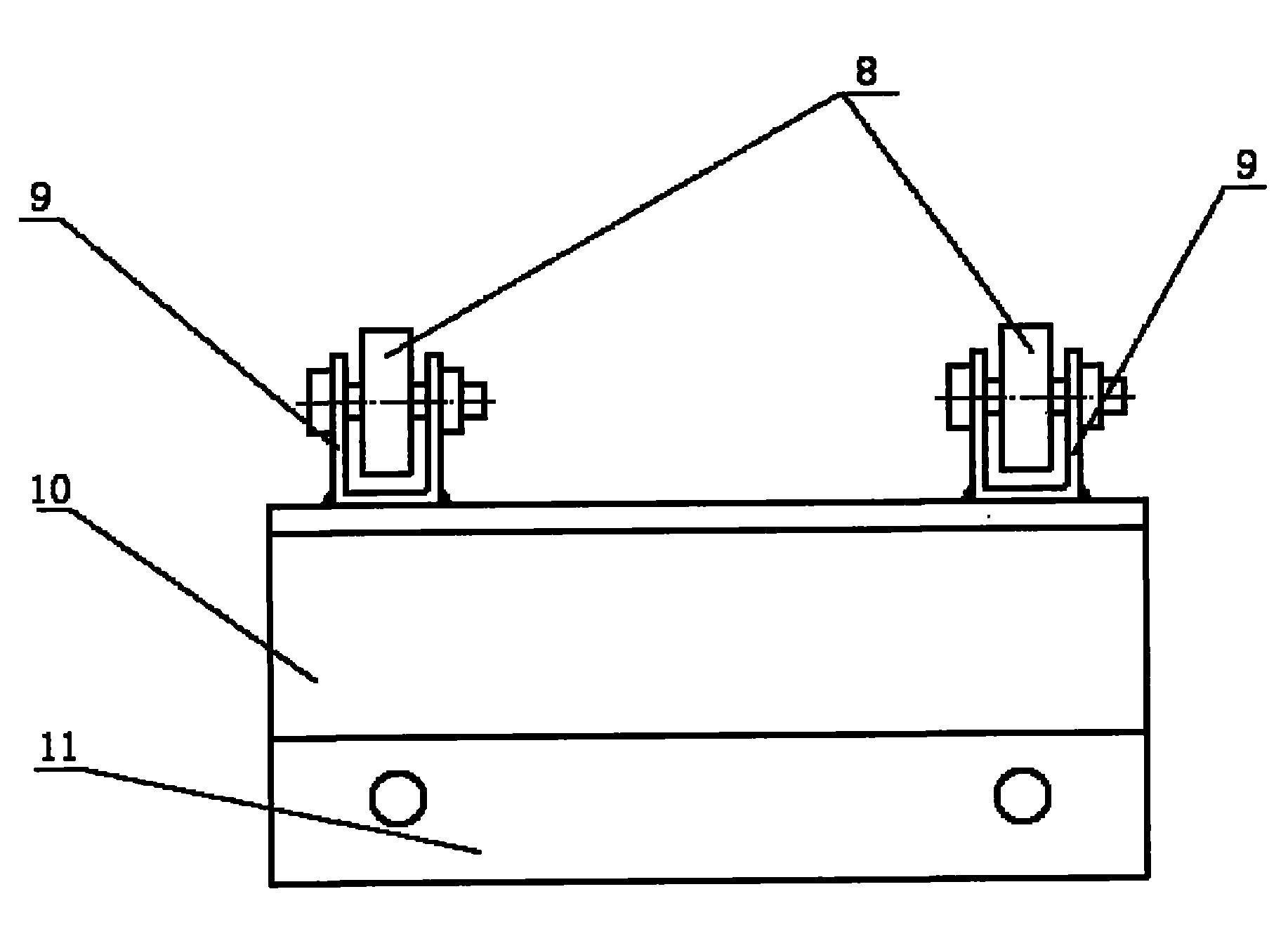

[0015] by figure 1 , figure 2 , image 3 As shown, a mold with a waste sliding part includes a waste chute 7, a rotating wheel mechanism 1, a pneumatic reciprocating mechanism, the waste chute 7 is arranged obliquely above the lower mold body 2, and the rotating wheel mechanism 1 is fixed to the lower mold On one side of the body 2, the rotating wheel mechanism 1 includes a connecting plate 11, a supporting angle frame 10, a wheel frame 9 and a rubber wheel 8. The connecting plate 11 is fixed on the lower mold body 2 by screws, and the wheel frame 9 is welded to the supporting angle frame 10 Above, the supporting angle bracket 10 and the connecting plate 11 are firmly welded. One end of the waste chute 7 is placed on the rubber wheel 8, and the distance between the two rubber wheels 8 can be adjusted, depending on the width of the waste chute, to ensure that the waste chute is stable when it moves. The pneumatic reciprocating mechanism includes a support plate 3 connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com